Resource Conservation and Waste Reduction

Reducing Waste

The recoverable reserves of the UACJ Group’s core material, aluminum, are abundant compared to other metals, giving it what is called a “long mining life.” Nevertheless, the Group believes it is important to promote reuse and recycling in order to pass on resources to future generations.

In recent years, marine plastic litter has become a major social issue highlighting the need to create a plastic-free and recycling oriented economy. With this in mind, we are actively expanding our recycling efforts for aluminum cans and automotive parts to include horizontal recycling, where a used product is recycled to use as a resource to make the same product again. We are also continuing efforts fulfill our environmental activity target to help realize a recycling-oriented society by working to lower our basic unit of industrial waste volume and by promoting the 5Rs, which add refuse and repair to the 3Rs of reduce, reuse, and recycle.

* “Horizontal recycling” refers to the use of scrap from used products to produce raw materials to make the same kind of products again.

Fiscal 2022 Results

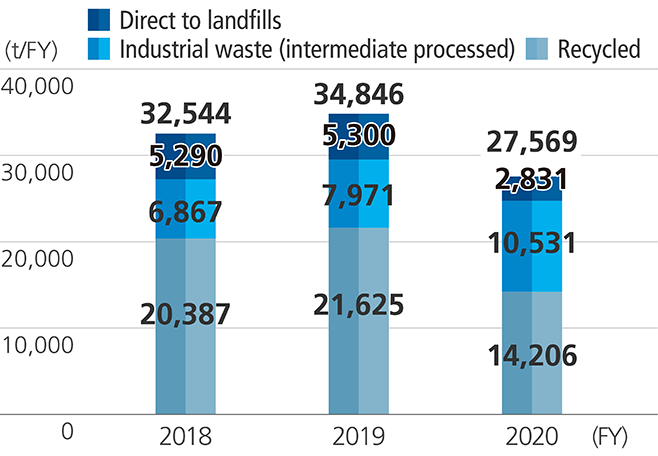

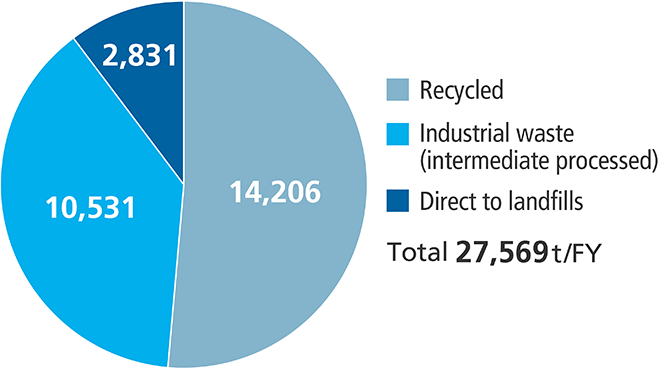

In fiscal 2022, the UACJ Group’s total volume of industrial waste generated at its production sites was 32,344 tons, a decrease of 0.7% compared to fiscal 2021. We attribute the reduction to the lower production volume and efforts to reduce waste plastics.

We will continue doing our part to create a recycling-oriented society by reducing and recycling industrial waste and promoting the conversion to more efficient resources.

The direct landfill ratio at our domestic business sites was 0.04%, as we continued to achieve our target of virtually zero emissions (direct landfill ratio of less than 1%).

Amounts of Industrial Waste Generated by the UACJ Group (Japan + overseas)

Breakdown of UACJ Group Waste by Handling Approach (FY 2022・Japan + overseas)

* Measurement scope:

(Through 2021)

(Japan) UACJ (Nagoya, Fukui, Fukaya), UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum), UACJ Extrusion Nagoya Corporation (Nagoya, Anjo), UACJ Extrusion Oyama Corporation, UACJ Extrusion Gunma Corporation, UACJ Extrusion Shiga Corporation, UACJ Foil Corporation (Shiga, Nogi, Isesaki), UACJ Foundry & Forging Corporation

(Overseas) UACJ (Thailand) Co., Ltd., UACJ Extrusion (Thailand) Co., Ltd., UACJ Extrusion Czech s.r.o., UACJ Foundry & Forging (Vietnam) Co., Ltd., UACJ Automotive Whitehall Industries, Inc., UACJ Foil Malaysia Sdn. Bhd.

(From 2022) All operating sites

Waste Amounts by Type and Main Post-Recycling Application (FY 2022, Japan)

| Waste Type | Tons Generated | Percent Recycled | Main Post-Recycling Application |

|---|---|---|---|

| Sludge | 8,222 | 90 | Raw material for cement |

| Waste oil | 3,158 | 94 | Fuel |

| Wood waste | 1,880 | 90 | Fuel, fertilizer |

| Waste plastic | 1,189 | 58 | Fuel |

| Slag | 1,160 | 100 | Roadbed material |

Industrial Waste Reduction Examples (Fiscal 2021 Activities)

| Business Location | Theme | Reduction (t/yr.) |

|---|---|---|

| Multiple operating sites | Reduction of waste plastics through reuse and conversion to value | 320 |

| Multiple operating sites | Reduction of sludge through improvement activities | 120 |

| Fukui Works | Reduction of waste plastics through reuse and conversion to value | 70 |

| Multiple operating sites | Reduction of paper waste through digitization of operations, etc. | 30 |

Industrial Waste Subcommittee

At UACJ, the Industrial Waste Subcommittee, consisting mainly of representatives of Japanese business locations generating significant amounts of industrial waste, meets regularly to promote reductions and proper processing of industrial waste. It does this by establishing a common understanding of separation and processing information, and by examining and promoting improvements in separation practices, and establishing a common understanding of reduction measures, at individual business locations.

Generation of Hazardous Waste

The UACJ Group is working to reduce emissions of hazardous wastes, such as strong acids, strong alkalis, and flammable waste oil, that are considered to put a heavy burden on the environment. We define hazardous waste in Japan as substances that are specially controlled industrial waste and overseas in accordance with the laws and regulations of each country.

In fiscal 2022, the UACJ Group generated 1,171 tons of hazardous waste (including 1 ton for direct landfill, 187 tons for intermediate treatment, and 983 tons for recycling) in Japan, and 10,984 tons (including 398 tons for direct landfill, 10,260 tons for intermediate treatment, and 326 tons for recycling) overseas. The Group engages in various types of efforts to reduce hazardous waste. One such effort is reusing sodium aluminate, a strong alkali that is a byproduct of the extrusion process, as a neutralizing agent for wastewater treatment at paper manufacturing companies.

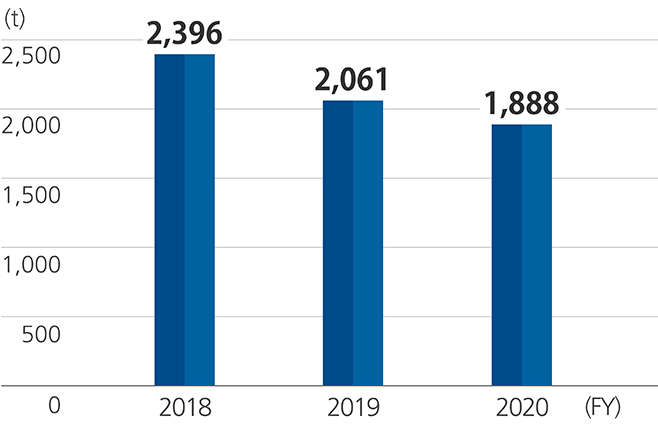

Reducing Amounts of Waste Plastic Generated

Packaging materials such as polyethylene sheets used for shipping products are increasingly being treated as industrial waste, especially after China stopped importing waste plastic several years ago. One of the ways we are seeking to reduce the amount of plastic used for our products is by working with our business partners to use thinner packing sheets. These and other efforts have helped us minimize the amount of waste plastic as industrial waste. We are also planning to increase the recycling of waste plastic in response to the growing demand from society with the adoption of the Act to Promote the Recycling of Plastic Resources in April 2022.

Waste Plastic Production Volume (Japan)

Reduction of Wood Waste

We promote the reuse, recycling, and conversion to other materials of wood used in our product materials and product packaging. Wood used to be the primary packaging material for some of our products but, because the wood materials were not recyclable and became industrial waste, we reengineered the packaging to use corrugated paper, for which recycling has become common. In fiscal 2022, we reduced waste wood by 181 tons (-8.8%) from fiscal 2019.

Amounts of Wood Waste Generated

Thermal Recycling of Packing Materials

We contract the handling of our waste plastics, such as protective sheets and binding bands for products used as packaging materials, to waste disposal companies that use the materials as a fuel source for thermal recycling (energy recovery), such as for incinerators that generate electricity primarily from waste materials.

Activities Aimed at Reducing Office Waste

At UACJ, individual offices act to protect the environment by separating their waste (separating paper from plastic) and segregating materials (newspapers, copier paper, magazines, and cardboard) for recycling.

Effective Use of Water Resources

Approximately 70% of the earth’s surface is covered by water, but only about 0.01% of all of the earth’s water is fresh water - water that can be easily used by humans.

From a global perspective, these precious freshwater resources are recyclable. With uneven distribution, however, there are already countries and regions facing serious risks of water shortages. Across the world, approximately 700 million people live with inadequate water supplies, and approximately 1.8 million children die every year because of a lack of clean water.

The UACJ Group strives to use and manage water resources effectively based on its keen awareness of these circumstances. Each of our business locations tracks its water usage by water source. Data on our water usage has been tallied and is included in the material balance information presented in the Business Activities and Environmental Impacts section.

Fiscal 2022 Performance

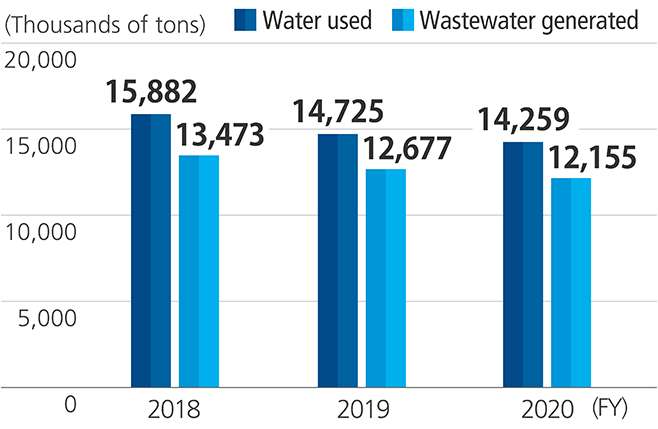

The UACJ Group source water for its operations mainly from groundwater and third parties (including industrial water and tap water), with the vast majority coming from third party sources.

Prior to discharge, the wastewater undergoes neutralization and coagulation-sedimentation treatment, and the water quality of the wastewater is evaluated using specific indicators*, such as pH, COD, and SS. Only wastewater that is verified as meeting statutory quality levels is discharged.

In fiscal 2022, the UACJ Group’s total water intake volume was 11,191,000 tons, a decrease of 523,000 tons from fiscal 2021. We attribute the reduction to the lower production volume.

*pH is potential of hydrogen, COD is chemical oxygen demand, SS is sedimentable solids

Volumes of Water Used and Wastewater Generated

* Measurement scope:

(Japan) UACJ (Nagoya, Fukui, Fukaya), UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum), UACJ Extrusion Nagoya Corporation (Nagoya, Anjo), UACJ Extrusion Oyama Corporation, UACJ Extrusion Gunma Corporation, UACJ Extrusion Shiga Corporation, UACJ Foil Corporation (Shiga, Nogi, Isesaki), UACJ Foundry & Forging Corporation

(Overseas) UACJ (Thailand) Co., Ltd.

Water Usage by Source (Japan + overseas)

(Thousands of tons)

| Water sources | Fiscal 2021 |

|---|---|

| Groundwater | 3,404 |

| Third party (industrial water, etc.) | 8,310 |

| Total water usage | 11,714 |

| Discharge destinations | |

| Fresh surface water (rivers, etc.) | 7,835 |

| Seawater | 273 |

| Third party (sewage water, etc.) | 1,743 |

| Total water discharge | 9,852 |

* Measurement scope:

(Japan) UACJ (Nagoya, Fukui, Fukaya), UACJ Color Aluminum Corporation, UACJ Extrusion Nagoya Corporation (Nagoya, Anjo), UACJ Extrusion Oyama Corporation, UACJ Extrusion Shiga Corporation, UACJ Extrusion Gunma Corporation, UACJ Foil Corporation (Shiga, Nogi, Isesaki), UACJ Foundry & Forging Corporation

(Overseas) UACJ (Thailand) Co., Ltd.