Business Summary

Flat Rolled Products Business

Utilizing World-leading Manufacturing Capabilities to Deliver High-quality Flat Rolled Products

UACJ boasts some of the most advanced aluminum sheet manufacturing capabilities in the industry, including precise thickness control technologies and one of the world’s largest rolling mills, measuring 400m long and 4.3m wide. This technological prowess enables us to supply the best products to a wide range of industries.

- Aluminum can stock and closure materials

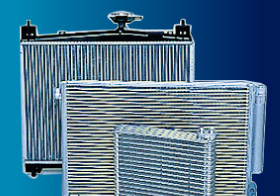

- Automotive heat exchanger materials

- BiW (Body-in-White) panels

- LNG tank materials

- Aviation and aerospace materials

- IT materials

- Air-conditioner compressor fin materials

- Liquid crystal and semiconductor equipment thick plates

- Litho sheet materials

- Construction plate

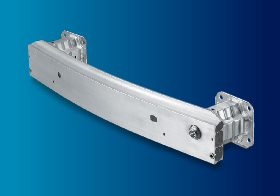

Automotive Parts Business

Supplying aluminum bumper assemblies, battery materials, and a wide range of other auto parts

UACJ is the top aluminum product manufacturer in Japan.

Leveraging the Company’s extensive know-how and technical expertise, the automotive parts business promptly responds to the needs of customers worldwide by supplying aluminum auto parts and components that meet strict requirements for high quality.

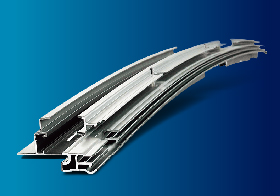

Extrusion & Metal Components Business (Extrusion)

Utilizing Comprehensive, Industry-leading Technological Prowess to Meet Needs in a Wide Variety of Fields

Supported by engineers highly experienced in manufacturing, molding design and various extrusion processing fields, UACJ utilizes its technological prowess to produce extruded products of the highest quality. Capitalizing on these comprehensive capabilities, we are able to meet the needs of customers from a wide variety of fields such as automotive, industrial machinery, aviation and office equipment. We continuously work to further improve technologies and quality at our production sites in Japan and overseas in order to better meet demands for higher quality.

- Automobile heat exchanger and tubing materials

- Motorcycle frame materials

- Photocopier photoconductive drum materials

- Machine parts materials

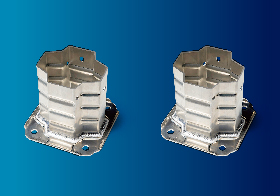

Extrusion & Metal Components Business (Metal Components)

Utilizing a Vast Array of Equipment and Technologies in Response to Various Processing Needs

From roll forming processes to joining processes, surface treatment and painting, UACJ has the facilities and technologies to respond to virtually any processing needs. Regardless of size, shape or function required, we’re ready to meet the needs of a wide variety of industries.

- Structural products

- Welded products

- Heat dissipation/cooling products

- Functional material products

Aerospace and Defense Materials Business

Providing One-Stop Service, from Material Development to Manufacturing and Finishing

We mainly manufacture castings and forgings used in aircraft, rockets, and other transportation equipment such as high-speed trains and automobiles. Utilizing our unique facilities, we have established an integrated manufacturing system that handles everything from research and development of aluminum materials to ingot-making, heat treatment, and finishing to supply high-quality products.

- Forged products for aviation and aerospace materials

- Forged products for railcars

- Forged products for liquid-crystal production facilities

- Turbocharger compressor wheels

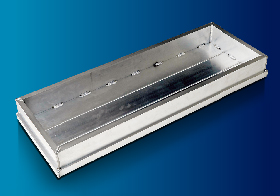

Foil Business

Utilizing Unparalleled Foil Technologies to Supply Products Designed to Meet the Latest Needs

UACJ produces aluminum and metallic foils of the highest quality for use in a variety of fields. Applications include everything from foil for lithium-ion battery current collectors and packaging for foodstuffs and products in the medical industry to everyday products like foil for use in the home.

- Medical industry and chemical products packaging foil

- Foodstuffs and packaging foil

- Lithium-ion battery current collector foil

- Daily-use foil