The History of Flat-Rolled Aluminum Production in Japan

Part 01

1898 to 1944

Founding the industry

and expanding as

a private enterprise

"We will do our utmost to establish

an aluminum product manufacturing business

that meets the needs of consumers"

Furukawa Electric's basic principle for conducting business, stated in 1930

The dawn of Japan's aluminum industry

In 1886, French engineer Paul Héroult and American engineer Charles Martin Hall independently developed an industrial aluminum smelting process using electrolysis (known as the Hall-Héroult process), marking a major historical breakthrough. Then in 1888, Austrian chemist Carl Josef Bayer discovered a process for extracting alumina from bauxite (known as the Bayer process). Aluminum had been a scarce and expensive metal, but these developments made it possible to dramatically reduce production costs and ensure high levels of purity.

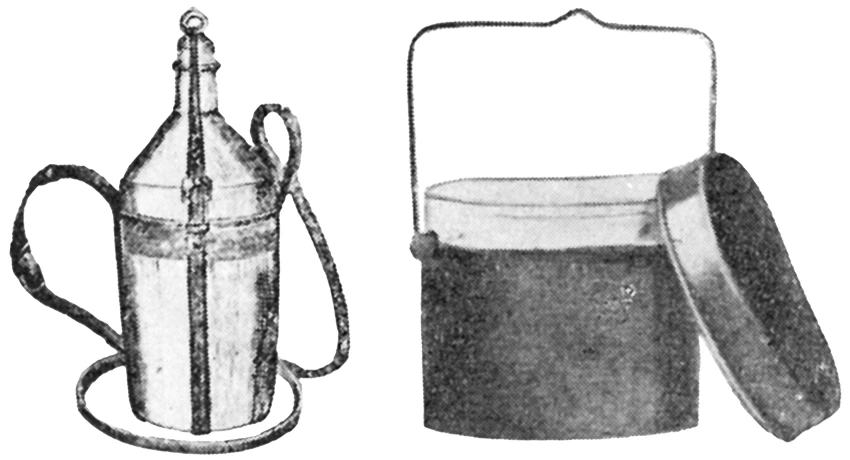

In Japan, it was the government that initially paid attention to aluminum, as it wanted to replace bamboo water bottles and wicker lunch boxes used by the military with modern aluminum versions like those in Europe. In 1894, the first domestically made aluminum canteens and mess kits were supplied to the military.

An aluminum canteen and mess kit, both made around 1894

Founding of Japan's first flat-rolled aluminum business

UACJ's roots extend back to businesses launched by a major family-run conglomerate, the Sumitomo Group, and an important industrialist, Ichibei Furukawa, around the turn of the 20th century.

The Sumitomo Group, which had grown wealthy by refining copper since in the early 1600s, established Sumitomo Copper Rolling Works in Osaka's Ajigawa district in 1897. While the group had used profits from its refining operations to expand into various businesses, such as trading and currency exchange, after encountering difficulties following Japan's Meiji Restoration from 1868, it decided to build the factory to manufacture copper products. Upon hearing this news, the Meiji government commissioned the factory to produce aluminum. In 1898, a year after the factory opened, the group became the country's first private enterprise to manufacture flat-rolled aluminum.

Ichibei Furukawa rapidly accumulated a fortune from a copper smelting facility he founded in 1884. Interested in the potential of aluminum, he commenced research on aluminum electrical wire and acquired a stake in an Osaka-based company that had set up an aluminum rolling mill in 1905. Later, Furukawa's own firm, Furukawa Mining Co., Ltd., absorbed this company by merger and began to manufacture flat-rolled aluminum.

The shop floor of Sumitomo Copper Rolling Works

Expanding aluminum rolling operations

In 1925, the Sumitomo Group moved the operations of Sumitomo Copper Rolling Works to a factory newly built in Osaka's Sakurajima district. Production lines integrating various processes from casting to rolling were installed in the new factory. The group went on to establish Sumitomo Metal Industries, Ltd., in 1935, which constructed another new factory, Nagoya Light Alloy Works (currently Nagoya Works), in 1941. Equipped with the latest technologies, the facility became the country's largest supplier of aluminum parts for aircraft.

Meanwhile, Furukawa Electric declared its basic principle for conducting business in 1930: “We will do our utmost to establish an aluminum product manufacturing business that meets the needs of consumers.” Then in 1933, the company increased its manufacturing machinery and built a new factory in the city of Nikko, Tochigi Prefecture (later renamed Nikko Works), equipped with a smelting furnace and forging equipment. This boosted production capacity of duralumin sheets and rods by about five times, and launched the flat-rolled aluminum business as the company's growth driver. Later, the company constructed a new forging factory and aluminum pipe and rod factory in the city of Oyama, also in Tochigi Prefecture, between 1943 and 1944.

The origins of extra super duralumin in Japan

In 1917, the Sumitomo Group set up Japan's first private sector research organization tasked with improving the country's technological capabilities. This led to the successful reproduction of duralumin, a new aluminum-copper alloy developed in Germany. The group branded it as Sumitomo Aluminum, built production facilities in 1920, and commenced mass production the following year. Around the same time, Furukawa Electric had been producing research prototypes of duralumin. After conducting full-fledged research in 1924, it commenced commercial production two years later.

In the years that followed, manufacturers around the world competed to develop a super duralumin exceeding the strength of the original duralumin. In Japan, however, users were calling for aluminum alloys even stronger than super duralumin. In 1936, Sumitomo Metal Industries succeeded in developing an “extra super duralumin,” later classified as the aluminum alloy 7075. In later years, this development prompted major advances in aircraft design, changing the course of history. Even today, 7075 remains in the top class of aluminum alloys in terms of hardness and strength, and is still used in a wide range of industries, such as transport and aerospace.

Duralumin was reverse engineered in Japan after researchers analyzed this fragment of the frame of a German airship.

Historical highlights 1

The Japanese first learned about aluminum in 1867 from a delegation returning from the world's fair held in Paris in the same year. The delegation reported “a high-priced, lightweight metal called aluminum” that had been exhibited. At that time, aluminum was very scarce and only used for luxury kitchen utensils in Europe since its production was extremely costly.

Gaining momentum from Japan's postwar revival

and rapid economic growth