The History of Flat-Rolled Aluminum Production in Japan

Part 02

1945 to 1972

Gaining momentum

from Japan's postwar revival and

rapid economic growth

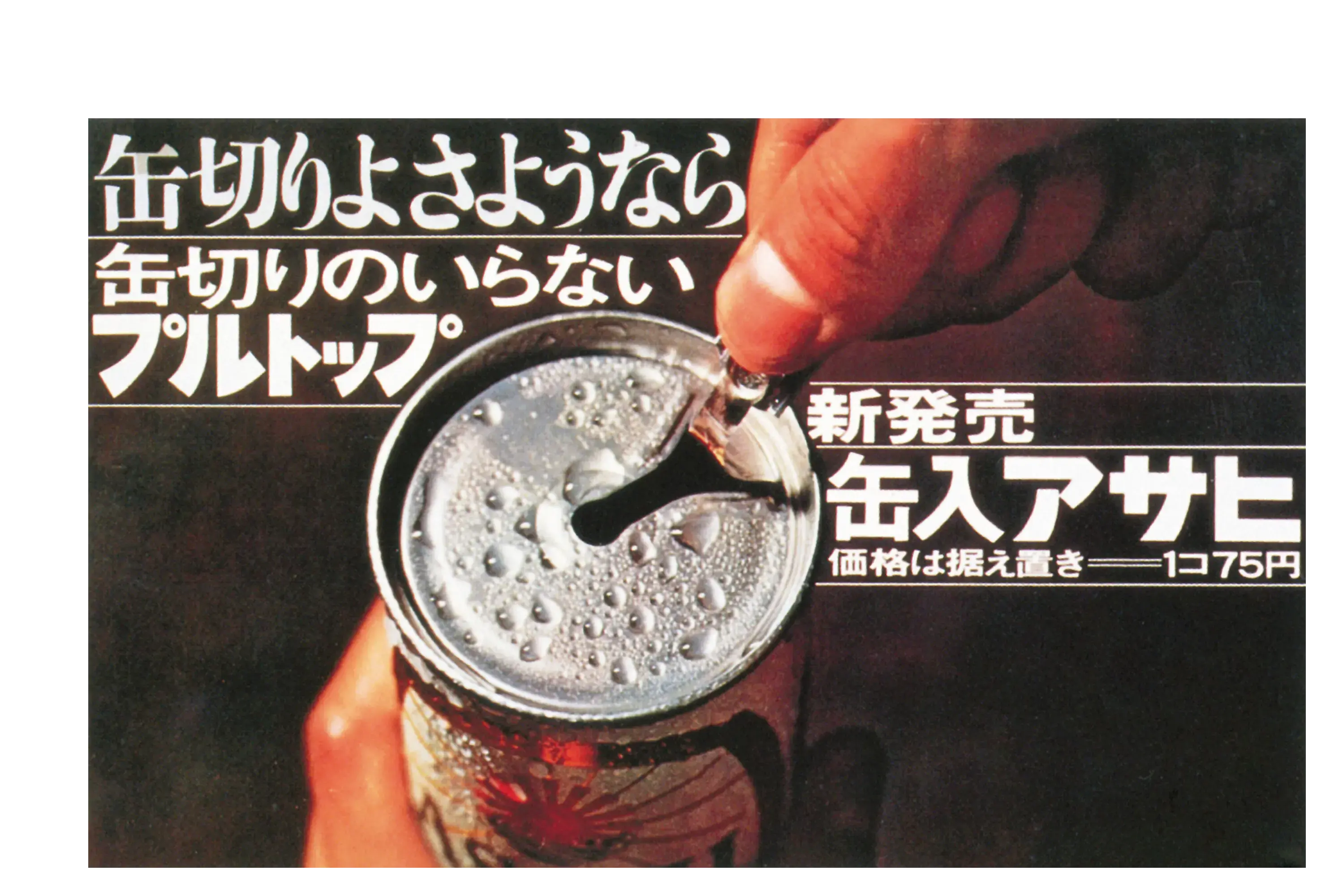

Sayonara to the can opener

This advertisement for aluminum cans with a pull tab was a hit with Japanese consumers in 1965.

New companies created as Japan rebuilt after the war

As Japan's economy grew dramatically following the end of World War II, the country's aluminum product manufacturers worked to enhance their technologies and boost production capacity to capture rapidly expanding markets. In 1959, Furukawa Electric Co., Ltd., formed a capital alliance with U.S.-based Alcoa Inc. with a view to acquire advanced technologies, and established Furukawa Aluminum Co., Ltd. In the same year, Sumitomo Metal Industries, Ltd., split off its aluminum business and established it as Sumitomo Light Metal Industries, Ltd. The new company then upgraded its facilities and installed one of Japan's largest hot rolling mills in 1966.

In 1964, another company that would play a major part in UACJ's history, Sky Aluminum Co., Ltd., was founded as a new flat-rolled aluminum manufacturer. Although a latecomer in the industry, it soon established a solid presence with the opening of its Fukaya Plant (currently Fukaya Works) in 1967, equipped with hot rolling machinery capable of producing the widest aluminum coils in the country at that time.

Celebrating the establishment of Sumitomo Light Metal Industries

Rapid economic growth pushes up demand for aluminum appliances and building materials

Japan's aluminum industry faced serious shortages of materials immediately after the war's end, and started reusing aluminum from airplanes to manufacture sheets and extruded items for everyday goods like pots, kettles, and lunchboxes. Around 1950, aluminum began being used in the transport industry for ships and aircraft, creating a bright outlook for aluminum producers.

From 1955, the aluminum industry expanded at a quick pace on the back of the country's rapid economic growth. Large-volume orders came from household appliance manufacturers, which, recognizing aluminum's light weight and rust-resistance, starting using the metal for the inner tub of washing machines. Within the span of just a decade, almost every Japanese household owned a washing machine, eliminating the labor of washing clothes with a washboard and basin. Then as household refrigerators became part of every home, aluminum manufacturers received steady orders for materials used in evaporators, an essential component for refrigeration.

In the 1960s, demand for aluminum window frames rose rapidly, prompting aluminum producers to build new factories. Aluminum had gained a strong reputation as a building material, and attracted widespread attention when it was used on the exterior of the country's first modern skyscraper completed in 1968. Amid this boom, Furukawa Aluminum established Furukawa Color Aluminum Co., Ltd. (currently UACJ Aluminum Center Corporation and Utsunomiya Color Aluminum Works) in 1972 as a dedicated manufacturer of color-coated aluminum.

An aluminum washing machine tub

Growing adoption of aluminum cans for soft drinks and beer

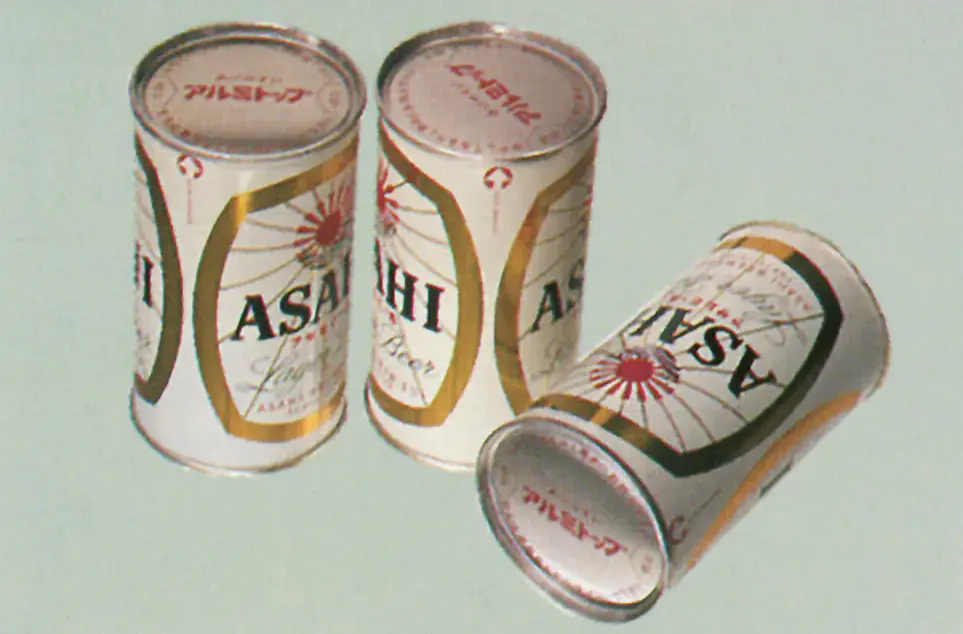

Another major trend in the 1960s was the growing adoption of aluminum cans. Producers had started using aluminum for food cans, and beer began being sold in aluminum cans in the United States from 1959. In Japan, Sumitomo Light Metal Industries developed flat-rolled aluminum for can lids in 1964 and supplied it to can manufacturers. Soon after, can lids came with a pull tab, eliminating the need for an opener. They were immediately popular in Japan thanks to a beer maker's advertising campaign declaring “sayonara” to the can opener. Later, Sky Aluminum began manufacturing aluminum for can bodies, enabling the production of all-aluminum cans for beer in 1971. Besides being light weight, the cans were highly regarded for preserving flavor and allowing detailed printing on the surface. Before long, aluminum cans were being used for soft drinks. Recognizing that the era of the aluminum can had begun, Sumitomo Light Metal Industries and Sky Aluminum expanded their production facilities to meet demand for can stock, which has continued to rise to this day.

Japan's first beer cans made with aluminum lids

Broadening applications to railway and energy sectors

With the rapid growth of Japan's economy, the country's railway network expanded at a fast pace. Aluminum was steadily adopted as materials for railway cars thanks to its light weight and strength. Sanyo Electric Railways, for example, replaced steel with aluminum for the body panels of its 2000 series of railcars that debuted in 1962, reducing the weight of the railcars by about 15%. This created various advantages for the railway, such as cutting down electricity consumption by 8% and reducing wear and tear on peripheral parts. From around 1967, aluminum was adopted for subway cars and shinkansen bullet trains. It was also used for container ships and semi-trailer trucks as applications continued to spread in the transport industry.

The use of aluminum also extended to the energy sector as extremely robust tanks were needed to store liquified natural gas (LNG), which had been attracting attention as a new energy source. For the gas to liquify, a temperature of minus 162 degrees Celsius must be maintained inside these tanks. Ahead of this trend, Sky Aluminum began developing aluminum thick plates for LNG tanks capable of withstanding such extremely low temperatures, and supplied them for Japan's first large-scale aluminum LNG storage tanks installed in 1968 at an industrial complex in Oita Prefecture.

Through such applications, aluminum became indispensable for industrial development and people's livelihoods during Japan's economic growth in the postwar period.

An LNG carrier with aluminum tanks

Historical highlights 2

In 1962, Sumitomo Light Metal Industries developed an innovative aluminum alloy called 7N01 (currently 7204) by adding zirconium. Offering high strength along with excellent resistance to corrosion and heat, the alloy was used in Japan to make railway car seat mountings and aircraft components. Applying the same technologies, the company developed an even more extrudable aluminum alloy called 7003 in 1967. This product was used for a broad range of applications, including container ships, semi-trailer trucks, and railway cars, particularly shinkansen bullet trains at a time when aluminum was being widely adopted by Japanese National Railways (currently Japan Railways Group, or JR) and subway operators. In addition, the 7003 alloy became Japan's first aluminum alloy to be registered abroad when it was registered by the Aluminum Association, a U.S.-based trade association for the aluminum production, fabrication, and recycling industries along with their suppliers.

Surviving the impact of global oil crises and

regaining momentum