The History of Flat-Rolled Aluminum Production in Japan

Part 05

2013 to the present

Moving forward as

an integrated aluminum products manufacturer

Putting aluminum at the heart of the circular economy

UACJ is striving to help build a sustainable world by taking advantage of aluminum's recyclability.

Aiming to maintain competitiveness in the global market as a new group of companies

In the 2010s, competition intensified in the aluminum industry as companies newly entered growing markets in Asia and other parts of the world. In Japan, however, no significant growth in demand for flat-rolled aluminum was projected due to the declining population and shrinking customer base, which had been relocating to other countries. Recognizing that the domestic aluminum industry had no future within the confines of Japan, Furukawa-Sky Aluminum and Sumitomo Light Metal Industries acted decisively by merging their businesses effective from October 1, 2013, forming UACJ Corporation and its large group of subsidiaries. Collectively, their annual production capacity of flat-rolled aluminum exceeded one million tons, the third highest in the world at that time. The UACJ Group was also unique in the global industry for having an operating company for each of its major businesses of flat-rolled products, extrusion, foil, casting and forging, and precision-machined products. As integrated aluminum product manufacturer, the UACJ Group now aimed to be a competitive player on the world stage. To realize this ambition, management announced the UACJ Group's Vision for the Future in March 2014, and its first mid-term management plan, Global Step I, in December of the same year, as a set of specific initiatives for each business under the vision.

Following the completion of this plan, management launched its second mid-term management plan in May 2018 with the goal of "maximizing the possibilities of aluminum in ways that contribute to society and the environment."

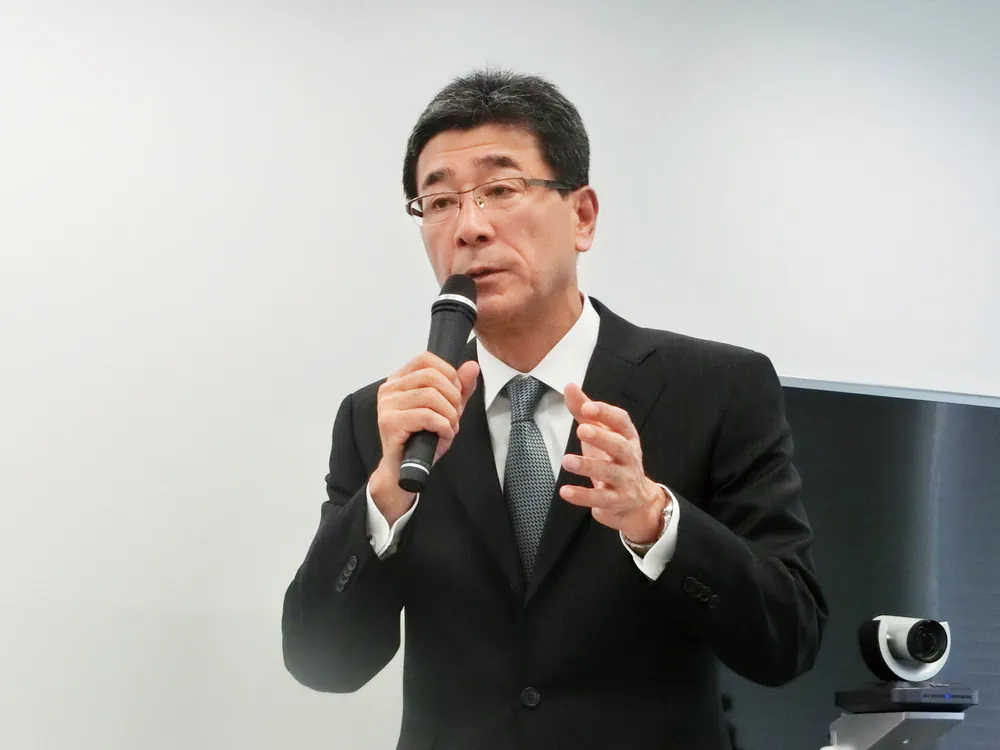

Former UACJ President Mitsuru Okada presenting the UACJ Group's Vision for the Future in 2014

Expanding manufacturing operations globally

Before the merger, Furukawa-Sky Aluminum had already been focusing on Thailand as a manufacturing base for meeting growing global demand for aluminum products. The country was home to a thriving automobile industry that needed a steady supply of aluminum parts, and many factories were being constructed by beverage makers, a source of demand for aluminum can stock. To tap this demand, Furukawa-Sky Aluminum established a subsidiary in Thailand and began constructing a large-scale manufacturing facility in the city of Rayong in March 2012, starting with a production line integrating all processes from cold rolling to finishing. With the establishment of UACJ in 2013, the subsidiary was renamed UACJ (Thailand) Co., Ltd.

The new facility, Rayong Works, commenced operations in January 2014. Despite various problems, including a fire caused by an equipment malfunction during rolling operations, a second phase of expansion of casting and hot rolling facilities was completed in August of the following year. Rayong Works then began operating as one of Asia's largest aluminum rolling mills, and was the first integrated flat-rolled aluminum plant operated by a Japanese manufacturer outside Japan.

UACJ (Thailand) has been working toward its goal of having Rayong Works operated primarily by domestic personnel. Rather than wholly adopting Japanese management practices, the company aims to build on its unique strengths by operating the factory according to best practices that suit its employees and local culture.

UACJ (Thailand)'s Rayong Works in 2015

Establishing a three-country manufacturing network

Demand for aluminum automotive parts and body panels had also been rising as automakers worked to improve fuel efficiency by reducing vehicle weight amid increasingly strict exhaust regulations in various countries, including the United States. Aiming to meet this growing demand, UACJ jointly established Constellium-UACJ ABS LLC in 2014 with Constellium N.V., a France-based conglomerate, to manufacture and sell automotive body panels in the U.S. To ensure a stable supply of base metals to this joint-venture and make its production of can stock more efficient, UACJ invested in the expansion of casting and hot rolling lines at Logan Mill, operated by its American subsidiary, Tri-Arrows Aluminum Inc.

By expanding these facilities along with Rayong Works, the UACJ Group accomplished its goal of establishing a three-country manufacturing network capable of supplying aluminum products worldwide.

Over the years, UACJ (Thailand) continued to train its workforce and boost annual production capacity at Rayong Works. Annual capacity surpassed 100 thousand tons in 2017, and the company expanded its customer base to more than 50 companies, which were not only in Southeast Asia but also Australia and the Middle East. With demand for aluminum can stock projected to grow across these regions, UACJ proactively invested in a third phase of new production facilities at Rayong Works to ensure a stable supply in the future. It also expanded Logan Mill in the United States, adding a casting line in 2018 and a cold rolling mill in 2020.

Besides increasing production capacity, UACJ internationalized its research and development organization by setting up R&D centers in both the United States and Thailand. Under the direction of its Research and Development Division in Nagoya, these new R&D centers have been collaborating with operations in Japan to develop new products for growing markets and provide prompt technical support.

Logan Mill operated by Tri-Arrows Aluminum in the United States

A casting facility under construction at Rayong Works

Responding to a tough operating environment with structural reforms

Demand for aluminum products fell sharply in 2018 due to trade friction between the United States and China along with a slowdown of China's economy. To boost profitability and competitiveness amid such difficult business conditions, UACJ launched a set of structural reforms in October 2019 with the goals of increasing earnings capacity, improving its financial structure, and increasing the speed and efficiency of management decision-making. The Company began by selling off its copper business in order to better allocate operating resources in the aluminum business. It also decided to close Nikko Works, a long-established facility originally founded by Furukawa Electric. Then in December 2019, it decided to liquidate Constellium-UACJ ABS, as progress in launching full-scale operations of this joint-venture company had fallen behind original expectations. As a result of executing these decisive measures, UACJ recorded positive free cash flow for the first time since its establishment in its consolidated financial results for the fiscal year ended March 31, 2020.

Rising demand for recycled aluminum and can stock amid growing environmental awareness

Prompted by the shift to electric vehicles, the automotive industry has been rapidly transformed by once-a-century technological innovations and new business models. Anticipating higher demand for aluminum automotive components as automakers strive to reduce vehicle weight, UACJ constructed a new factory building at its Fukui Works in July 2020 to mass-produce body panels. It also invested in new equipment to boost production capacity of aluminum automotive parts made by its subsidiary, UACJ Automotive Whitehall Industries, Inc., in the United States, and formed a partnership with subsidiaries of CITIC Group Corporation in China to produce such parts for the Chinese market.

At the same time, UACJ has been stepping up its development of automotive components made from recycled aluminum in response to customers that aim to reduce the environmental impact of their manufacturing operations. This led to the successful adoption of recycled aluminum body panels for the Toyota Mirai, a hydrogen fuel cell vehicle, in December 2020. The panels were jointly developed with Toyota Motor Corporation.

Meanwhile, demand for aluminum can stock remained strong in North America amid rising environmental awareness and a shift away from the use of plastic. From 2020, household consumption of canned beverages rose rapidly due to the impact of lockdowns in urban areas during the COVID-19 pandemic. Tri-Arrows Aluminum successfully met this brisk demand for can stock, its mainstay product, by supplementing its production in the United States with shipments from the UACJ Group's operations in Japan and Thailand.

In July 2019, UACJ (Thailand) began operating new production facilities following UACJ's third phase of investment in Rayong Works. This immediately boosted output and sales volume, resulting in the first quarterly profits posted by the subsidiary in the 2019 October-to-December quarter. From the outset of 2021, sales volume increased markedly on the tailwind of strong international demand for can stock. Although logistics costs rose sharply due to the pandemic, UACJ (Thailand) remained profitable and recorded record-high sales volume in fiscal 2021, ended March 31, 2022, by leveraging its production and sales capacity to capture robust market demand.

A continuous annealing and processing line newly installed at Fukui Works

Long-term management vision extending through 2030

The UACJ Group renewed its corporate philosophy in February 2020 and carried out various events for promoting it group-wide, including round-table discussions among senior managers and employees. To concisely express the philosophy and its vision for the future, the Group created a new corporate slogan in 2021, “Aluminum lightens the world.”

In May 2021, the Company announced its long-term roadmap for contributing to society, UACJ Vision 2030, along with a third mid-term management plan designed to realize the vision.

In the same year, the Company formulated the UACJ Group Sustainability Policy, recognizing that for a business to supply aluminum, an essential metal for building a sustainable planet, it must also operate sustainably. Likewise, the Group specified six materiality issues to prioritize in its initiatives, including its response to climate change. Accordingly, it set ambitious targets for reducing Scope 1 and 2 CO2 emissions with the goal of becoming carbon neutral by 2050.

To make the most of the environmental benefits offered by aluminum, the Group began taking steps to reduce its environmental burden across the entire supply chain, and implement various initiatives for putting aluminum at the heart of the circular economy. For example, UACJ (Thailand) and Tri-Arrows Aluminum began recycling scrap aluminum using specialized melting furnaces. In Japan, UACJ formed an alliance with Toyo Seikan Group Holdings to promote closed-loop recycling of aluminum cans1, and is leading efforts to establish a domestic recycling system for used beverage cans in collaboration with Yamaichi Metal Corporation. In addition, UACJ has joined and acquired certification from the Aluminum Stewardship Initiative, and international certification organization.

In October 2023, UACJ celebrated the 10th anniversary of its establishment. By leveraging the strengths of each of its businesses, the UACJ Group has been providing products and solutions globally for a decade. With an unwavering belief in the potential of aluminum, the Group will continue making the most of the metal's benefits to contribute to society and the environment going forward.

UACJ's corporate slogan and logo

Historical highlights 5

In recent years, the public has increasingly recognized that aluminum can help reduce environmental impacts. Many people are aware, for example, that recycling rates for aluminum cans are comparatively high compared to other materials. In Japan, 93.9% of aluminum cans were recycled in 2022, and the can-to-can recycling rate (the percentage of all recycled cans reused again as cans) reached 70.9%, up 3.9 percentage points compared with the previous year. Aluminum cans can be recycled again and again without reducing the aluminum's quality, so progress in recycling can continue far into the future.

Founding the industry and expanding as

a private enterprise