Kensuke Goto

Head of the Global Sales Planning & Promotion Department

Mr. Goto has been a sales manager for a wide range of UACJ products. He joined the sales department at UACJ (Thailand) in 2014 where he oversaw sales of automotive heat exchanger materials and later moved to sales of can stock to global manufacturers. In 2020, he became Head of the Global Sales Planning & Promotion Department at UACJ Corporation where he is in charge of strategic planning for global sales.

Three Turning Points for Overseas Operations

Expanded capacity at UACJ (Thailand)

opens avenues to untapped markets

The UACJ Group’s supply framework for can stock has been structured for the production base in Japan to supply the Japan market, Tri-Arrows Aluminum in the United States the North American market, and UACJ (Thailand) the Thailand and Southeast Asian Market. This structure was used because we needed to ensure we could provide a stable supply to our domestic customers in Japan, who required unique specifications. Also, Tri-Arrows Aluminum needed to focus on meeting the rapidly growing demand for can stock in the United States, which is the world’s largest user of aluminum cans. UACJ (Thailand) had annual production capacity of under 200,000 tons, so it was dedicated to supplying the local market in Thailand and neighboring countries.

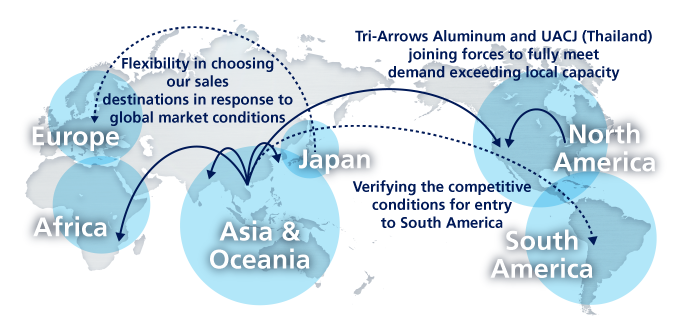

However, the third phase of investment to expand the production facilities at UACJ (Thailand) raised its annual production capacity to 320,000 tons in 2019. At the same time, local operators have become increasingly proficient and have doubled their monthly production volume to above 20,000 tons. Enhanced output by UACJ (Thailand) will allow us to supply to a wider base of users, and the company has even extended its supply range to the growing markets in Africa and the Middle East. The expanded supply range will not only increase sales, it will also diversify risk. The company is also preparing to broaden its coverage to include South America, where demand is also growing for can stock.

UACJ (Thailand) also gives us flexibility when choosing our sales destinations, allowing us to respond to changing global market conditions caused by trade agreements, tariffs, or other developments. One example is the trade friction between the United States and China. Aluminum demand in the United States surged when it restricted the import of Chinese products, and UACJ (Thailand) was able to help Tri-Arrows Aluminum meet demand that was beyond its capacity. Likewise, UACJ (Thailand) started delivering to South Korea to avoid tariffs placed on products from Japan. Bolstered by the augmented production capacity, the UACJ Group’s sales activities are branching out to reach new regions around the world.

Expanded supply range is bringing

new business with global manufacturers

The UACJ Group’s Can Stock Business has advanced to the next stage with the capacity expansion at UACJ (Thailand) and the ability to offer high quality products to new customers around the world. This new stage is enabling business with global beverage and can manufacturers. Global manufacturers need suppliers who can provide a large volume of can stock worldwide that is of consistent quality and highly cost competitive during contracts that last several years. These are the minimum standards to be considered as a candidate to supply can stock. UACJ is now positioned to meet and exceed those standards. The enhanced capacity of UACJ (Thailand) and the increase to an annual capacity of 450,000 tons at Tri-Arrows Aluminum in the United States with the further support from the 300,000 tons produced annually in Japan give us the stable supply system needed to become a business partner of the global manufacturers.

In addition, the three production bases previously only supplied locally and were considered to be operating as three distinct companies. However, managers from the three companies advocated for combining forces to create a global supply network. Customers have even noticed the difference, saying that we have become a global corporation, and we are now recognized as a fully unified group. I believe that this change in how our customers see the Group is significant.

Of course, a global supply system is not enough to win contracts.

Successful business negotiation requires appreciating a country’s business customs and national character and understanding the customer’s way of thinking and the speed of their decision-making. I realized this when I was on global sales team at UACJ (Thailand). One time when an American senior executive and I were in a sales meeting we were asked to give a price quote. In Japan, providing a quote usually takes time to formulate because we would consult with superiors and do other preparations. However, the American executive gave them a rough estimated right away. Although he had been authorized to enter a business deal, he also seemed to have an intuitive understanding that an on-the-spot decision would lead to a successful business negotiation and a satisfied customer. For the Group to increase its business partnerships with global manufacturers, we must develop human resources that have that sort of global business sense.

We must become a genuine global player to expand business with global customers

Bud PatelUACJ (Thailand) Co., Ltd.

General Manager Global Business Sales & Marketing Dept.

For the UACJ Group to establish key points of contact with global customers, it will need to promptly acquire information on important market trends and the competitive environment along with feedback from customers by being directly connected to the marketplace. To accomplish this, we must allocate key sales personnel who can establish and maintain long-term relationships with our customers and be directly involved in negotiations without needing the support of a trading company. Therefore, these individuals should be groomed over the long term instead of having their jobs rotated every several years. UACJ must aim to be a global player rather than just a Japanese company doing global business, and I am happy to say that it has already established a strong global presence in the global can stock market.

Identifying emerging needs at global manufacturers

Global manufacturers primarily need stable supply in all parts of the world and cost competitiveness. At the same time, those manufacturers have innumerable contacts with end users, and have a diverse array of both apparent and latent needs. It will not be enough for the UACJ Group to grow by meeting the natural rise in demand as populations increase and emerging countries expand economically. We also must have the structure to respond to a wide range of needs, including potential needs.

The Group is fully aware of this and has supplemented its R&D base in Japan with new bases in the United States and Thailand. The local bases shorten the time needed to respond to customers because we can examine their requests and issues locally without having to bring them to Japan. Communication in the local languages also enables immediate and more detailed responses. The overseas R&D bases will also develop products geared to local potential needs and will be actively involved in boosting sales and enhancing customer satisfaction.

Our customers are also increasingly concerned about environmental issues. In the last year or two, many customers started asking us for specifics about the percentage of recycled materials in our products and what our targets are. Now, these topics are discussed by virtually of our customers. We are also often asked if UACJ is a member or planning to join the Aluminium Stewardship Initiative. ASI is an international organization aiming to maximize the social contributions of aluminum producers, processors, and end users around the world by strengthening the sustainability throughout the aluminum supply chain. We were the first Japanese aluminum rolling manufacturer to join ASI. Beverage manufacturers of well-known brands as well as can manufacturers are strongly pushing for sustainability measures. My many years of experience in sales tells me that sustainability is going to continue to be a major buying factor in the years ahead.

One environmental problem that has gained a lot of attention recently is the plastic pollution from plastic bottles,

bags, and other waste that is flowing into the seas and having a tremendous impact on the marine ecosystem. Industries are responding by using less plastic in containers and packaging. Although not yet big enough to measurably affect aluminum demand, some beverage packaging companies in the United States are offering aluminum cups as an alternative to plastic cups used at baseball stadiums and outdoor events. We have even switched to serving water in aluminum cans to visitors to the Company. Among beverages, mineral water is the largest market, and converting even just 1% of that market to aluminum cans would add huge demand for aluminum. As we demonstrate the value of the UACJ Group in the global market, we will seek to form new markets while being sensitive to the demands and changes at our customers and in society.

Visitors to UACJ are served water in aluminum cans