Special Feature(January 2016)

In August 2015, the UACJ Group established a fully integrated manufacturing network and commenced full-fledged operations at the Rayong Works of UACJ (Thailand) Co., Ltd. (UATH), which the Group is positioning as its core Asian factory. Here, we again introduce some of the Rayong Works’ characteristics.

Rayong Works in an Ideal Location for Demand and Distribution

The Rayong Works, with an extensive site measuring around 500,000m2, is located in the center of Asia. This facility is home to numerous manufacturers of cans and heat exchangers, which are made from aluminum materials. The plant is approximately 100km from the international airport serving Bangkok, Thailand's capital, and around 30km from a port. This advantageous location should allow the Rayong Works to leverage its high production capacity on both the demand and distribution fronts to support the development of the Asian economy.

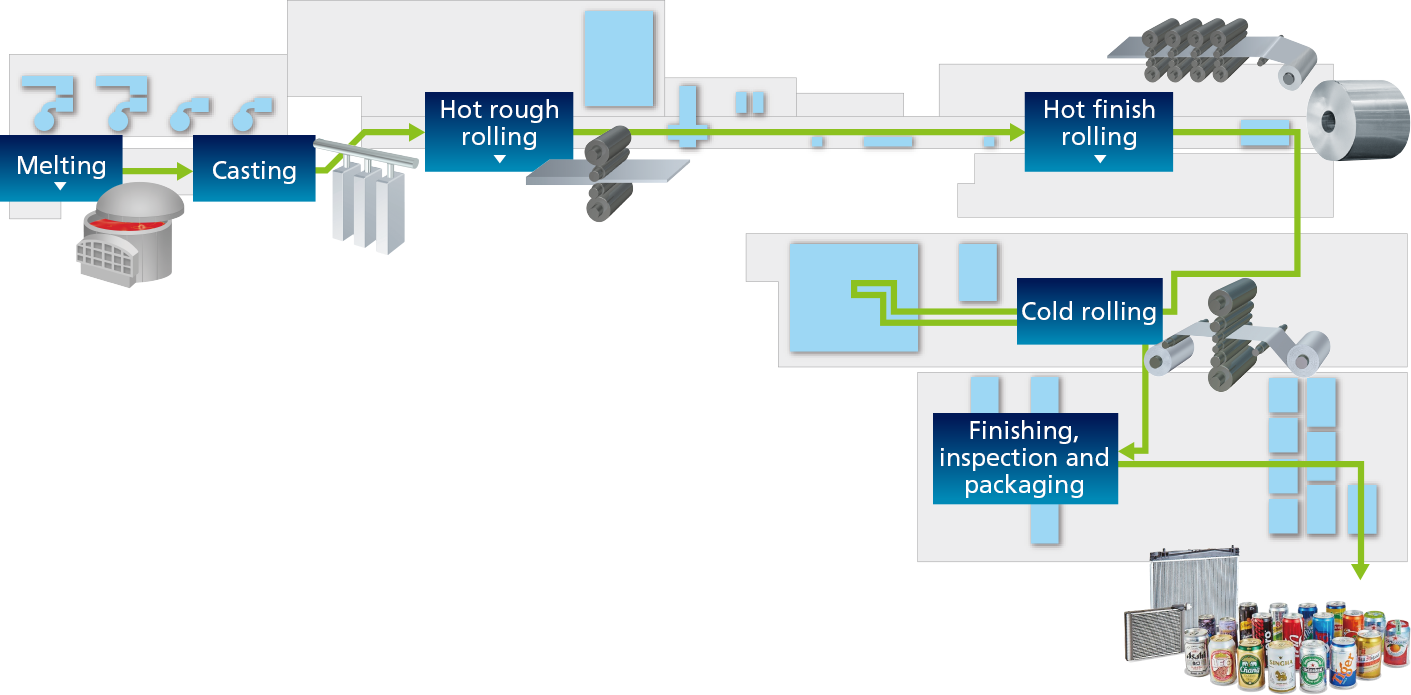

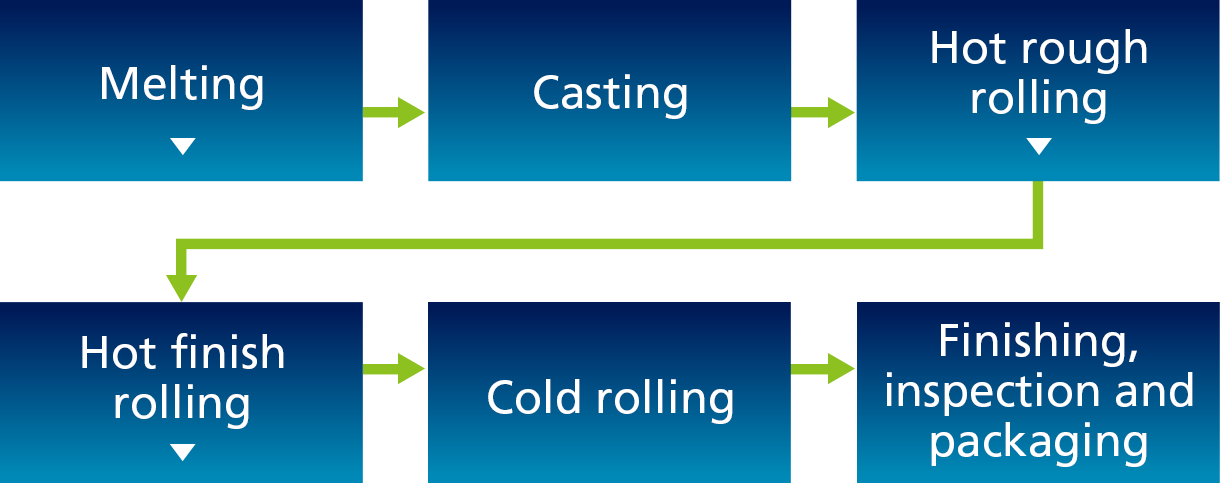

The Fully Integrated Manufacturing Line, Now Completed, and Principal Equipment

- A large-scale facility that can respond to demand increases

- Fully integrated manufacturing from casting to finishing allows for speedy supply

- Rayong Works’ sheet materials used in beverage cans and heat exchangers

Principal Equipment

- Melting and Casting Furnace

- A melting and casting furnace capable of simultaneously producing five large ingots weighing 33.5 tons

- Hot Rough Rolling Mill

- A large, 372m-long rough rolling mill that rolls 500mm-thick ingots down to around 30mm by running the material repeatedly through its rollers 15 times

- Hot Finishing Rolling Mill

- A four-stand continuous rolling mill that rolls 30mm plates down to uniform sheets 2–3mm thick

Message from UATH President Yamaguchi

We will contribute to manufacturing in Thailand by localizing UACJ’s manufacturing prowess.

As the person responsible for UATH, I aim to contribute to the company’s development of production in Thailand, as well as the expansion of the UACJ Group. To this end, we are working to combine the DNA we have inherited—high-quality manufacturing capabilities cultivated in Japan—with the local culture and employee temperament to create Thai-style manufacturing. Eventually, I believe we will reach the stage where the company can be operated entirely by local employees.

The first steps will be to educate our employees and invest in resources to expand our facilities, as we work to create a manufacturing system on a par with those in Japan. In the future, we intend to create a network that will allow us to ship products not just in Asia but also to countries in the Middle East and throughout the world. At the same time, we will consider increasing the variety of products we offer.

UACJ (Thailand) Co., Ltd.