Special Feature(December 2017)

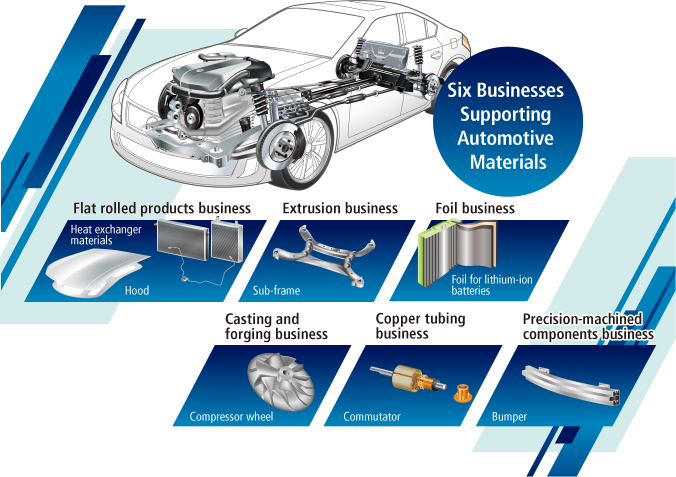

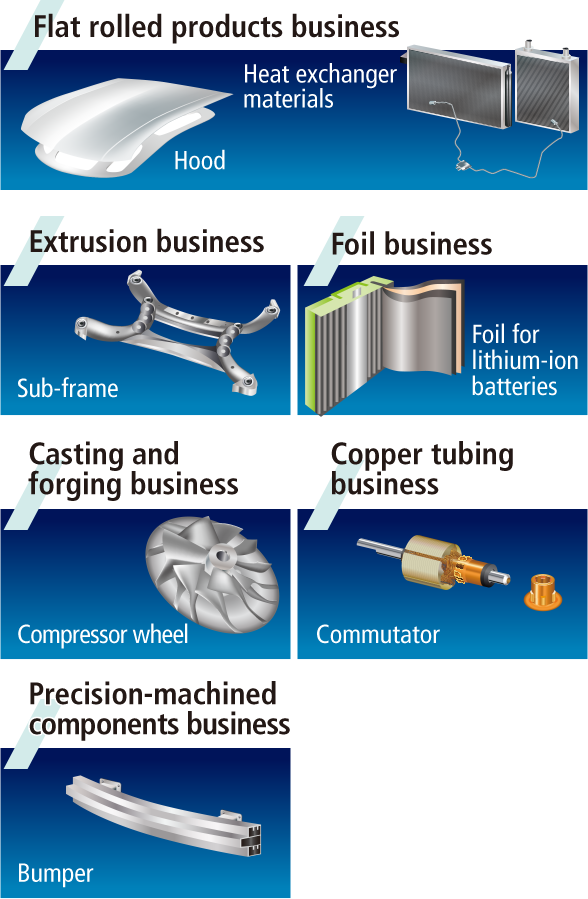

Aluminum is being used more frequently as a material befitting “automotive advancement” as vehicles become more lightweight and are increasingly powered by electricity.

In this section, Kazuhisa Shibue, chief executive of the Research & Development Division, discusses the future of automobiles and UACJ’s efforts to cultivate further applications for aluminum.

Developing Materials One Step Ahead of the Adoption of Electric Vehicles

As environmental regulations on automobiles grow increasingly stringent, the trend toward more lightweight vehicles and the adoption of electric vehicles (EVs) is accelerating. The materials of which EVs are made differ from their engine-powered counterparts, and as EVs become increasingly popular, demand to develop EV-specific materials is growing. In addition to existing automakers, companies from other fields are energetically entering the EV field. As a materials manufacturer, we see this as a chance for market cultivation.

As a materials manufacturer, we see this as a chance for market cultivation.

The UACJ Group views this transformation of the automotive industry as a major business opportunity. Accordingly, we are stepping up our R&D into aluminum materials for EVs. We are developing storage battery materials, such as electrolytic aluminum foil for lithium-ion batteries and aluminum alloy sheets for battery cases, as well as other materials that anticipate EV needs, such as lightweight structural materials to help extend the cruising range.

Creating New Value through R&D into New Materials and New Production Technologies

To foster increased demand for aluminum, we need to cultivate new applications and work to reduce costs. UACJ is collaborating with large automotive parts manufacturers to develop new joining technologies that should help improve productivity and lower costs. In addition, we are participating in an industry–academia collaboration project sponsored by the New Energy and Industrial Technology Development Organization (NEDO) in an effort to develop a refining process that will make aluminum more cost-competitive. Going forward, we will continue to pursue R&D to create new value for aluminum.