Special Feature (December 2022)

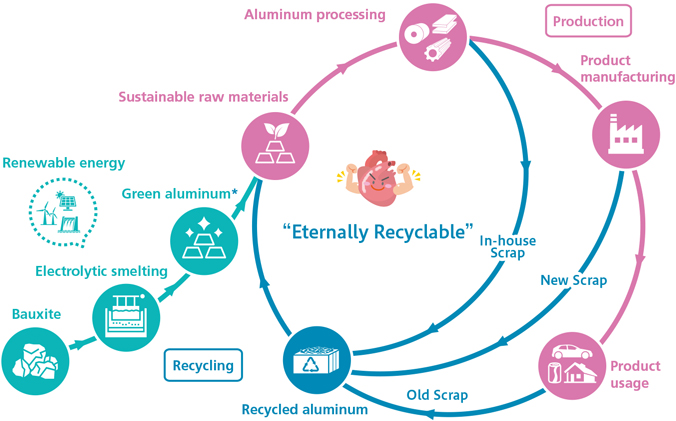

Aluminum can be recycled into the same products over and over again, making it an indispensable material for the planet. We can tackle the global issue of reducing CO2 emissions by recycling aluminum, but a number of hurdles still must be overcome to establish such recycling systems. As a company specializing in aluminum products, UACJ is taking the lead in addressing these challenges and is determined to play a central role in the industry going forward.

*1 Aluminum produced using electricity from renewable energy sources to lower the environmental impact

Benefit 1 Lower environmental impact at the aluminum smelting stage

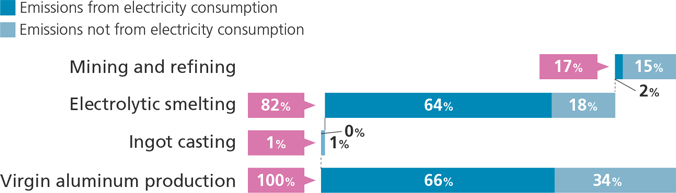

A vast amount of electricity is consumed to produce virgin aluminum. In fact, electricity consumption accounts for 66% of all greenhouse gases (GHGs) emitted from mining to smelting and the final casting of ingots. The smelting stage, however, can be eliminated by recycling aluminum, thereby drastically reducing GHG emissions. Because it is recognized as a metal that can help alleviate environmental burdens, global demand for aluminum is on the rise. Since this demand cannot be met by recycled aluminum alone, production of virgin ingots is still necessary.

Therefore, efforts are underway to produce these ingots using electricity from renewable energy sources in the smelting process, and widely supply this “green aluminum” to the world.

Breakdown of GHG emissions from virgin aluminum production

- Source: Data published by the International Aluminum Institute

Benefit 2 Lower environmental impact of recycled aluminum

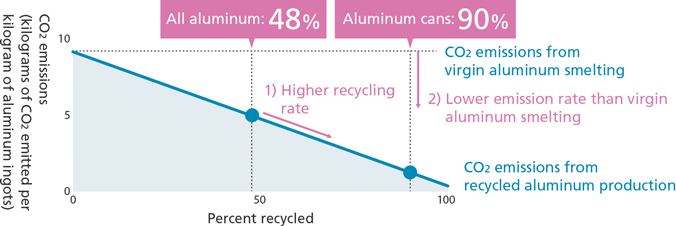

Recycled aluminum production emits only about 3% of the CO2 emitted from the production of virgin aluminum ingots. Accordingly, raising the aluminum recycling rate can substantially reduce environmental impacts at the product manufacturing and usage stages. Significant progress has been made in aluminum can recycling, especially, but challenges remain for recycling other aluminum products. To provide solutions for these challenges, UACJ is collaborating with business partners while drawing on its many years of expertise in aluminum alloy processing and development to set up systems for recovering aluminum from products besides cans, and exploring ways to remove impurities that accumulate as recycling is repeated.

Comparison of aluminum recycling rates and CO2 emissions

- Source: Aluminium Vision 2050 published by the Japan Aluminium Association in September 2020

- Formula: (CO2 emissions from virgin aluminum smelting) x (1 – percentage recycled) + (CO2 emissions from recycled aluminum production) x (percentage recycled)

UACJ’s initiatives for spurring advances in recycling methods

Developing an alloy production process to allow the use of various kinds of scrap

The varying properties of scrap aluminum, even when the same alloys are collected, is an obstacle to recycling. To overcome this hurdle, UACJ is applying its expertise built up over many years to develop an alloy production process that allows various kinds of scrap aluminum to be used in the same way as new aluminum ingots.

Enabling scrap aluminum to be recycled directly

Directly recycling scrap aluminum into new materials can reduce the overall environmental impact of recycling operations. Toward that end, the Company has established an integrated aluminum can recycling system that allows scrap to be used as is, without any special treatment.

Developing technologies for sorting different alloys and removing impurities

Closed-loop recycling can be greatly facilitated if aluminum scrap is sorted by the types of alloys. Therefore, in collaboration with customers, UACJ plans to step up efforts to sort and retrieve processed scrap aluminum. Furthermore, the Company is working to develop and apply new technologies, such as ionic liquid smelting, to remove impurities from collected scrap, which would allow it to be used in the same way as virgin aluminum.

Benefit 3 Lower environment impact at the product usage stage

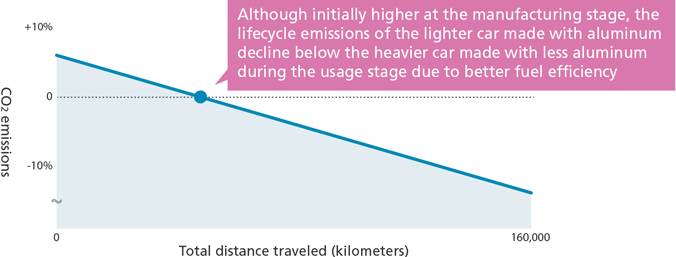

Among aluminum’s many beneficial properties, its light weight can contribute to reducing environmental impacts during the product usage stage. For example, using aluminum auto parts to reduce overall vehicle weight helps reduce CO2 emissions.

Environmental impacts can be reduced substantially if aluminum materials suited for all-new applications are developed and supplied in the future. From that standpoint, the Company is widely promoting its UACJ Smart brand of environmentally friendly products, working with other manufacturers in educational and branding initiatives, and accelerating its development of aluminum products for new applications.

Lifecycle CO2 emissions of a car made with aluminum