UACJ Assets

Environmental Initiatives

Environmental Management

Towards Realizing a Sustainable Society

The UACJ Group considers environmental conservation and realization of a recycling-oriented society important management issues. In addition to abiding by environmental laws and regulations and corporate statutes, we are working to reduce the environmental impact of all business activities.

To promote environmental management throughout the Group, we establish UACJ Group Environmental Policies every year, setting objectives for reducing environmental impact during business operations in that year. These policies are developed in accordance with basic environmental policies based on the UACJ corporate philosophy and guidelines. Under the policies, we carefully consider the environment in all stages of the product lifecycle, from development and manufacturing to sales, use and recycling.

Maintaining Environmental Management Promotion Systems

We have established a Group-wide Environmental Committee, chaired by the Chief Environmental Officer, to promote environmental activities and raise environmental awareness among employees. As a general rule, the committee meets one time each year to discuss policies and goals related to environmental activities. At the same time, the Environmental Safety Division works to ensure the practical implementation of policies and goals.

Additionally, environmental management systems are in the process of being implemented at all Group sites, and nearly all production sites have acquired ISO 14001 certification. Some of our smaller facilities have also acquired Eco Action 21 certification in accordance with guidelines released by Japan's Ministry of the Environment. All sites carry out initiatives based on management systems and work to continuously upgrade certifications.

Preventing Global Warming

Saving Energy at Every Stage Beginning from Manufacturing Processes

As a means of contributing to the prevention of global warming, the UACJ Group has introduced initiatives to reduce the use of energy throughout all business activities, including everything from manufacturing and distribution to the use of electricity in offices.

During manufacturing processes, in particular, where energy consumption is high, we are promoting initiatives to improve production efficiency at each site and are switching to substitute fuels, among other measures.

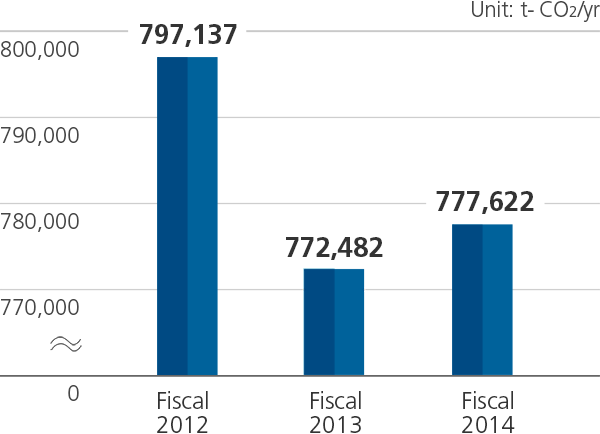

As a result of the reallocation of product mixes, which we have been carrying out since the merger, productivity has risen. Additionally, both CO2 emissions and energy consumption per unit of production have improved over the previous year.

Furthermore, Energy Conservation Subcommittee meetings—cross-departmental meetings centered around the Facilities Department—are held periodically. During these meetings, information is shared between sites and the utilization of effective energy-saving examples is promoted throughout the Group.

- * Measurement Scope: UACJ (Nagoya, Fukui, Fukaya, Nikko), UACJ Color Aluminum, UACJ Extrusion Nagoya (Nagoya, Anjo), UACJ Extrusion Oyama, UACJ Extrusion Gunma, UACJ Extrusion Shiga, UACJ Foundry & Forging, UACJ Foil (Shiga, Nogi, Isezaki), UACJ Copper Tube

Preventing Environmental Pollution

Strict Voluntary Targets Set to Reduce the Emission of Environmental Pollutants

The UACJ Group has established its own voluntary emissions targets for air, water and soil pollutants, and is committed to maintaining them. These targets are stricter than those required by laws, regulations and agreements.

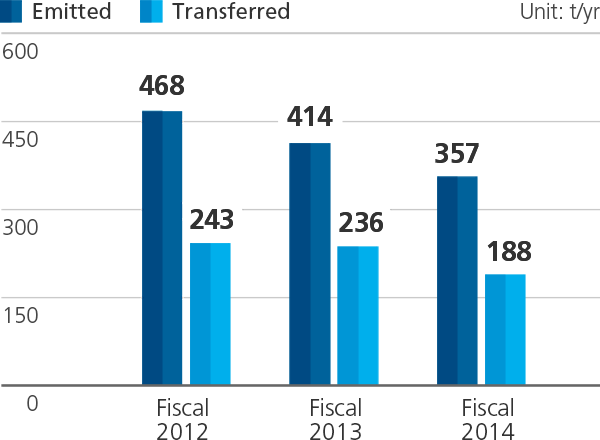

Regarding initiatives for chemical substances, all Group companies record the volumes of targeted substances handled, emitted and transferred in accordance with the Pollutant Release and Transfer Register (PRTR*) law. In addition to reporting these values, the Group is working to further reduce the use of targeted substances. In fiscal 2014, despite an increase in production, due to successful reduction activities, the total amount of targeted substances decreased. Overall, Group-wide emissions were reduced 20.3% compared to the previous fiscal year.

* Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof (Act No. 86 of Japanese Law announced on July 13, 1999)

(including manganese, chromium, nickel and lead alloy elements in products)

* Measurement Scope: UACJ (Nagoya, Fukui, Fukaya, Nikko), UACJ Color Aluminum, UACJ Extrusion Nagoya (Nagoya, Anjo), UACJ Extrusion Oyama, UACJ Extrusion Gunma, UACJ Extrusion Shiga, UACJ Foundry & Forging, UACJ Foil (Shiga, Nogi, Isezaki), UACJ Copper Tube

Reducing Waste

Aiming for Zero Emissions at Main Business Sites

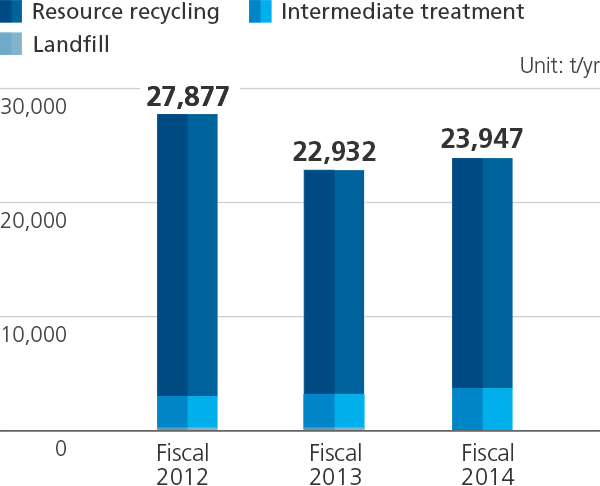

In order to help realize a recycling-oriented society, the UACJ Group is working to reduce industrial waste. Member companies carry out waste sorting and recycling with the ultimate goal of achieving zero emissions.* In fiscal 2014, the ratio of waste directly consigned to landfills was 0.39% at our main business sites, meeting the targeted objective. We will continue to work to maintain zero emissions in the future as well.

* Zero emissions is defined as a ratio of less than 1% of total industrial waste being disposed of directly to landfills.

* Measurement Scope: UACJ (Nagoya, Fukui, Fukaya, Nikko), UACJ Color Aluminum, UACJ Extrusion Nagoya (Nagoya, Anjo), UACJ Extrusion Oyama, UACJ Extrusion Gunma, UACJ Extrusion Shiga, UACJ Foundry & Forging, UACJ Foil (Shiga, Nogi, Isezaki), UACJ Copper Tube

Recycling Aluminum Cans

Aluminum can be recycled using approximately 3% of the energy required to produce new aluminum from bauxite ore. Capitalizing on this highly efficient characteristic, the recycling of aluminum cans has progressed considerably, reaching a current recycling rate of approximately 90%. As a leading aluminum products company, UACJ is taking the initiative in can recycling, and supporting activities on behalf of the Japan Aluminum Can Recycling Association.

Developing Eco-conscious Products

Focusing on the Development of Eco-conscious Products with Low Environmental Impact

The UACJ Group is highly conscious of harmonizing with the environment even at the product development stage.

In recent years, aluminum's characteristic lightweight and durability have attracted attention to the metal for application in the production of automobiles and other forms of transportation, where the lighter weight achieved contributes to better fuel efficiency and reduces energy consumption. In order to respond to the increasingly diversified demands of society, we are working to improve the characteristics of aluminum materials and developing products that are lighter yet maintain the same functionality as when manufactured with conventional materials.

Additionally, taking maximum advantage of the highly efficient recyclability of aluminum, we are developing practical can stock that is even easier to recycle.

Other activities include collaborating with customers to develop a variety of eco-conscious aluminum products that will reduce impact on the environment, including highly efficient heat exchanger tubes capable of contributing to saving energy, car air-conditioner materials compatible with non-Freon refrigerants, and materials for hybrid and fuel-cell vehicles.