UACJ Subsidiary Introduces Leading-Edge Extrusion Machine to Expand Automotive Parts Business in North America

Management

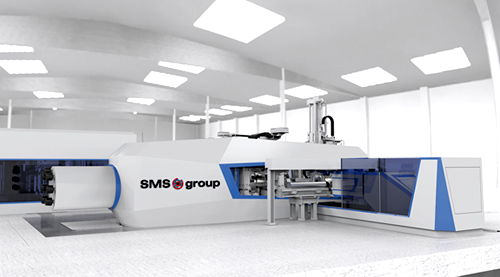

UACJ Automotive Whitehall Industries, Inc. (Headquarters: Michigan, United States; President: David Cooper; “UWH”), a subsidiary of UACJ Corporation (Headquarters: Chiyoda-ku, Tokyo; President: Mitsuru Okada), will introduce a leading-edge HybrEx® extrusion machine manufactured by SMS group GmbH (Headquarters: Düsseldorf, North Rhine-Westphalia, Germany; CEO: Burkhard Dahmen, “SMS”) in response to a sharp growth in North American demand for automotive aluminum structural materials and parts. This adoption by UWH marks the extruder’s first introduction in the North American market.

UWH, a leading company in the provision of aluminum structural materials and parts, is primarily targeting the expanding automotive aluminum materials market in North America. Through extremely precise aluminum extrusion processing technology and a high level of productivity, UWH has established a unique industry position for the provision of services unmatched by competitors. The company has a particularly high share of the market for automotive sunroof guides and body frame structural materials. Joining the UACJ Group in April 2016, UWH is working to establish global alliances and accelerate its automotive business.

The HybrEx® 25, a leading-edge extrusion machine, will enable UWH to provide high-quality parts at low cost. Compared with conventional extrusion machines, the HybrEx® 25 features reduced working times and accepts longer billets, boosting productivity by more than 20%. The model is also environmentally friendly: as electric power consumption and the burden of extruder maintenance are reduced, energy use is 55% lower and noise is decreased.

The extrusion machine is scheduled to commence operation on a trial basis in 2017, with full-fledged operations commencing in or after 2018. The structural materials the extrusion machine produces are slated for delivery primarily to automotive manufacturers in North America, enabling the company to respond precisely to surging demand for structural materials and machined parts.

SMS’s extrusion machine, the HybrEx® 25