“ALmitas+” Honeycomb Panels to Be Used in Making Lacquer Panels

—Combining Traditional Craftsmanship Techniques with Aluminum, Which Is Recognized for its Lightness, Durability, and Quality, in Interior and Furniture Items—

Development

UACJ Corporation (head office: Chiyoda Ward, Tokyo; President: Shinji Tanaka) announced today that the honeycomb panels manufactured at the Koriyama Plant of its consolidated subsidiary, UACJ Metal Components Corporation (head office: Chiyoda Ward, Tokyo; President: Yasushi Kita) have been approved for use in the traditional craft of making lacquer panels. This project is part of the brand development of the ALmitas+ brand of aluminum materials and products, and recognizes aluminum's characteristics of lightness, durability, and quality. We hope these materials will be used in a variety of items in the future, including interior decorations and furniture.

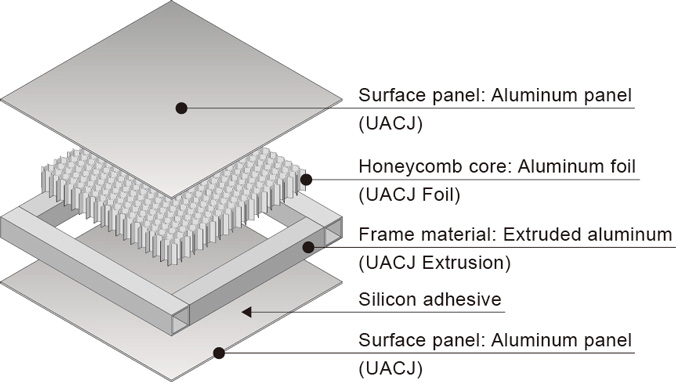

These lacquer panels are art panels developed jointly by APLUS Co., Ltd. (head office: Kaga, Ishikawa Prefecture; President: Hirotsugu Sakamoto), which is involved in the planning, production, and sales of lacquerware, and Monko LLC (head office: Setagaya Ward, Tokyo; President: Takeshi Tamura), which works to promote and expand sales of Japanese traditional craft products and materials overseas. The “Honeycomb Panel” is made of aluminum foil in the shape of a beehive, sandwiched between aluminum panels, and is covered with paint and using the maki-e techniques of Ishikawa's traditional craftsmanship. This is the first time for UACJ's Honeycomb Panel to be used in traditional crafts.

Left: Aluminum Honeycomb Panel before painting

Right: lacquer panels after painting

Looking Ahead to Future Developments in Lacquer Panels

Lacquer panels are made using traditional lacquer painting techniques, with each piece painted by craftsmen, mirror-finished, and threaded with gold threads used in Nishijin-ori textiles*. The process of drying after painting must be repeated several times, requiring substantial time and labor. Conventional panels use wood for the base, which requires the opposite side to be painted as well to prevent the boards from warping when drying. With aluminum Honeycomb Panels, only one side of the panel needs to be painted, reducing the amount of labor required by craftsmen. In addition, aluminum is lightweight, moisture resistant, and durable.

To promote the value of aluminum as a material in itself to the world at large, in September 2023 we began developing “ALmitas+” as a new brand of aluminum materials and products for the UACJ Group. One of the four policies of the UACJ Group’s long-term roadmap, UACJ Vision 2030, is to “utilize materials +α to contribute to greater social and economic value through our value chain and supply chain.” In line with this policy, as Japan's leading comprehensive aluminum manufacturer we have begun to develop this brand to lead the way in increasing the value of aluminum.

We will continue to expand the added value of “materials + α” and provide aluminum materials to various fields to foster the “ALmitas+” brand and support people's daily lives and industry.

* The lacquer panels with gold threads are finished with polyurethane and UV coatings.

About Honeycomb Panels

Honeycomb Panels are made using a honeycomb core of aluminum foil in the shape of a beehive, sandwiched between aluminum panels. The concepted was researched and developed in the United Kingdom around 1940 to reduce the weight of aircraft, and was industrially produced in the United States. In Japan, Sumitomo Light Metal Industries, Ltd. In Japan, UACJ's predecessor began research and development and commercialization of this technology in 1980.

Because of their light weight, strength, and high degree of flatness, these panels are used in various fields, including building materials and industrial products.

About “ALmitas+”

ALmitas+ is a brand of aluminum materials and products handled by the UACJ Group. Based on the technology that the UACJ Group has cultivated over the years, this project will co-create with various partners to convey the ever-expanding possibilities and appeal of aluminum. In addition to existing areas, we are expanding the field by developing new applications focusing on products that add new functions to aluminum materials.

Origin of the Name

The name derives from a Japanese shortening of the word “aluminum” and the Japanese for “add.” The name represents the brand image of adding fun and excitement to aluminum materials and products.

About UACJ

UACJ Corporation is an integrated aluminum manufacturer doing business globally. Under the slogan “aluminum lightens the world,” we aim to contribute to the realization of a sustainable and prosperous society through technology that harnesses the power of materials.

UACJ, which was established in 2013 through the business integration of Furukawa-Sky Aluminum Corporation and Sumitomo Light Metal Industries, Ltd., has a history in rolling aluminum stretching back more than 125 years. The UACJ Group has five businesses: Flat Rolled Products, Automotive Parts, Extrusion & Metal Components, Casting and Forging, and Foil. We support people's daily lives and industry by supplying aluminum materials across a wide range of fields, for beverage cans, automobiles, IT equipment, air conditioning, and the aerospace industry.

In the fiscal year ended March 31, 2024, the UACJ Group had consolidated revenue of ¥892.8 billion and approximately 10,500 employees.