The Challenge of UACJ Rayong Works — The People Who Built the Factory from Zero

- HOME

- Aluminum lightens the world

- UACJ Stories

- The Challenge of UACJ Rayong Works — The People Who Built the Factory from Zero

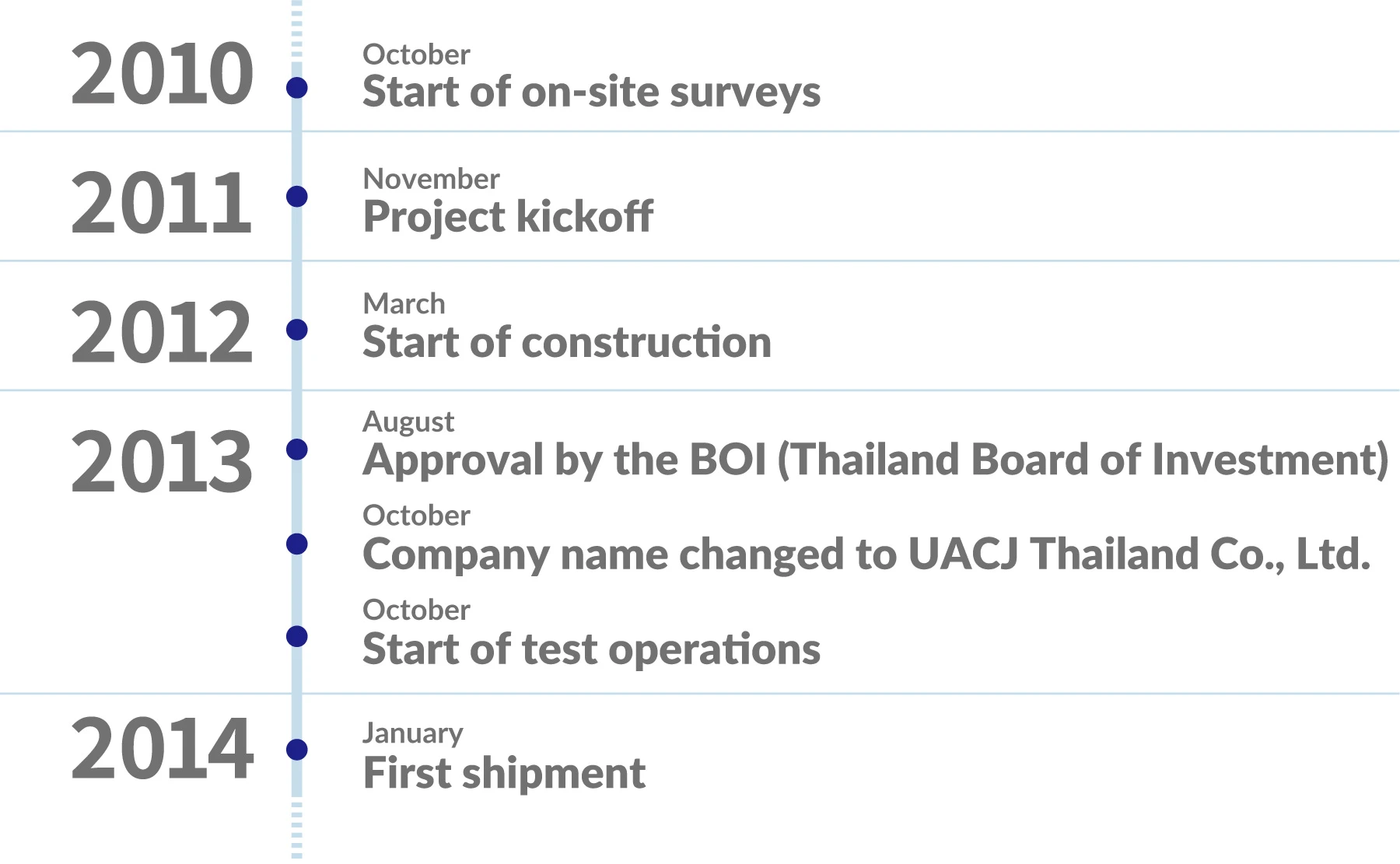

On October 1, 2013, two leading Japanese aluminum manufacturers, Furukawa-Sky Corporation and Sumitomo Light Metal Industries, integrated to form UACJ Corporation.

The expertise of these two long-established aluminum processing firms, which supported Japanese industries through beverage and food packaging materials, materials for automotive and transport equipment, HVAC components, and building materials, merged into one, propelling a “Japan-origin, major global aluminum product manufacturer” into its next stage.

Its symbol is the Rayong Works in Rayong Province, Thailand, one of the largest flat rolled aluminum factories in Southeast Asia. Through a greenfield strategy, it just began from zero, with driving stakes into an empty plot, and building electricity, water, roads, talent, and a supply chain entirely from scratch.

Establishing a new base overseas was a comprehensive effort that required equipment relocation, dealing with ground conditions, and developing systems and people all at once. We spoke with the startup members who led this “challenge from zero” about the decisions made at the time, the realities on site, and the future that lies ahead.

- Interviews were conducted at both the Japan and Thailand sites.

SPEAKER

Akitoshi Yamaguchi

Executive Adviser

UACJ Corporation

Yasuo Toba

Principal Manager

Internal Auditing Section

Internal Auditing Department

UACJ Corporation

Kiyoshi Kawamoto

Assistant to Chief Executive

Production Division

UACJ Foil Corporation

Takayuki Gunji

General Manager

Accounting Department

UACJ Trading Corporation

Kotaro Arita

Senior Manager

Administrative Department

UACJ Thailand Co., Ltd.

Taking Japanese Technology Overseas —

The Challenges and Decisions Behind It

——Please tell us what led UACJ to take the step toward overseas expansion.

TobaAt the time, the extremely strong yen made exports from Japan unprofitable, and domestic demand was also stagnant. Meanwhile, the demand for aluminum for automobiles, can materials, and other uses was rapidly expanding in Southeast Asia and the Middle East, making it clear that “the growth markets are overseas.”

KawamotoWhat we were targeting was the local supply of flat rolled aluminum products in those fast-growing regions. Producing close to the demand centers increases supply speed and enhances cost competitiveness.

Competitors in Japan had already begun expanding overseas, so we felt a strong need to make an early decision as well.

Yamaguchibelieve this was ultimately the period when we were confronted with the reality that “we cannot rely solely on a fully mature domestic market.”

The decision to establish a new base overseas was not merely a cost-related measure, but the first step for UACJ to transform itself into a truly global company.

——Among the options for overseas expansion, why did you choose Thailand?

TobaIn addition to Thailand, Malaysia, Vietnam, and Indonesia were also considered as candidates. The comparison points were demand, labor costs, infrastructure stability, and taxation. Looking at all the conditions comprehensively, Thailand had the best overall balance.

In addition, the tax incentives offered by the BOI (Thailand Board of Investment) and the relative ease of obtaining work permits were major factors that supported our decision to expand there.

YamaguchiThe biggest reason we chose Rayong was to avoid flood risk. There had been a major flood in Ayutthaya in the past, and we were determined not to repeat the same situation. Rayong has high elevation and is resistant to flooding, and its proximity to the Laem Chabang Port made it ideal as a production base with exports in mind.

——What was the site like in the very early stages of establishment?

GunjiI remember there being a huge number of flies, as the site had originally been a pineapple field. I could truly feel that we were starting from nothing.

YamaguchiSince the construction was from zero, we encountered issues. During the installation of the cold rolling mill, the equipment sank. The ground in Rayong was supposed to be very firm, but for some reason, it sank. Later investigation showed that the decomposed granite near the surface had weathered and weakened, causing the foundation to settle.

KawamotoThe construction site was located on land with hills and valleys. For the filled valley areas, we drove piles, and for the cut hill areas, we used direct foundations.

However, the weathering of the decomposed granite had progressed in the direct foundation areas. Ultimately, the site team injected concrete to repair the foundation and managed to stabilize it.

YamaguchiThe ground subsidence was caused by a “slaking phenomenon,” a rare case in Thailand in which bedrock rapidly weakens when exposed to air or water. This experience deepened our understanding of the geology, and from the second phase onward, we improved the precision of ground reinforcement to ensure more reliable construction.

——Please tell us what led to the decision to relocate the cold rolling mill from the Nikko Works to Thailand.

KawamotoSince the plan for the first phase was to start operations as quickly and cost-effectively as possible, we decided to relocate the cold rolling mill that had been used at the Nikko Works. It was a proven piece of equipment, which gave us confidence in terms of quality, but because it was an older machine, we often had to repair it while using it. Including the training for local staff on its operation, the startup involved many challenges.

AritaWe also had a strong desire to “pass Japanese technologies on to the next generation.” By bringing the technologies and expertise accumulated in Japan to Rayong, we aimed to strengthen the production framework of the entire Group. It truly felt like “entrusting the spirit of Japanese technology to Rayong.”

How Trust Shaped the Team

——As factory operations became fully established and Japanese and Thai staff began working together, did you experience any differences in culture or ways of thinking?

KawamotoPeople in Thailand place great importance on relationships, while also drawing clear boundaries in their work. They are caring but do not step beyond their defined responsibilities. At first, these differences were confusing, but by establishing clear job descriptions and defining roles explicitly, we were able to create an environment where both sides could work comfortably.

YamaguchiIn Japan, there is a tendency to act without being explicitly stated, while in Thailand, the basic approach is to “follow what has been decided exactly as decided.” At first, this difference was confusing, but it also showed a strong adherence to rules, and it made us realize the importance of preparing clear standards. This experience became a major turning point in rethinking our operational systems.

GunjiI also felt cultural differences in the office. In Thailand, there is a belief in “respecting another person’s work,” and some employees do not dispose of their own trash, out of respect for the cleaning staff’s role. I was surprised at first, but once I understood the background, I realized there was a lot to learn from it.

AritaIn Japan, there is often an expectation that saying one thing will be enough for the other person to understand ten, but in Thailand, you need to clearly communicate all ten points. At first, this difference was confusing. The culture of reporting, sharing information, and consulting also differs, and misunderstandings sometimes occur. However, by shifting to a more step-by-step and thorough approach, and by engaging in continuous dialogue, we developed a way of working that makes use of each other’s strengths. I believe this has become one of the strengths of the Rayong Works today.

——As a member of the startup team, were there any challenges that you found particularly difficult?

TobaWhat left the strongest impression on me was the question of what is required to create a workplace where people stay. When I was first assigned, I was responsible for launching the Quality Assurance Department, but there were times when the leaders we had trained left unexpectedly, which pushed me to think seriously about how to create an environment where people would want to stay long term.

I therefore made sure to value everyday interactions, not just work-related communication. To build trust with local staff, I also tried to communicate directly rather than relying on interpreters. Looking back now, the trial-and-error approach during that time became the foundation of learning how to develop people.

KawamotoIn terms of equipment, it was a constant “race against time,” and the startup phase involved daily troubleshooting. During construction, we often could not understand Thai well enough to convey detailed instructions, and we had to rely on having local staff learn by observing us. I still look back on that as an area for reflection.

Even so, the local staff worked extremely hard to understand the Japanese way of doing things, and their efforts often exceeded our own. Thanks to that commitment, I believe the Rayong Works exists as it does today.

GunjiI had a very difficult time obtaining approval from the BOI (Thailand Board of Investment). Although we began preparing from the moment I was assigned, we could not see the progress of the review, and we repeatedly revised the application documents. With a limited communication infrastructure at the time, we spent many nights coordinating documents between Thailand and Japan. Working in parallel without knowing when approval would be granted was mentally very demanding.

AritaFor me, the biggest challenge was the language barrier. When I was first assigned, I was the only Japanese person in the office, and everyone around me was Thai. I could hardly communicate at first, and I felt like a “ghost employee.”

Feeling a sense of urgency, I enrolled in a Thai language school, studying two hours after work on weekdays and ten hours a day on weekends. After about two months, I was finally able to hold conversations, and from there, my relationships with local colleagues changed dramatically.

Learning the local language is the best way to bridge emotional distance. I believe the effort I made during that time shaped who I am today.

YamaguchiFor me, the biggest theme was “localization.” Even during the rush of the startup, I always believed that the factory should be led primarily by Thai staff.

Looking back now, localization is still only halfway achieved. The ratio of Japanese staff remains high, and there is still more to be done to create an organization that truly operates through local capabilities. This remains one of the major challenges for me even today.

Growth and the Future Seen Beyond the Challenge

——Is there anything you would like to pass on to the next generation?

GunjiThe trial and error during the startup phase continues to support who I am today. As we created systems and rules together as a team, I came to realize that “a company is built by its people.”

I hope the next generation will not fear working in environments that are not yet fully established and will experience the enjoyment of shaping things on their own.

KawamotoThose involved in this project learned a great deal from a continuous cycle of challenges and trial and error. I would be glad if our experiences serve as a meaningful foundation for the next generation. Even a short period of wholehearted dedication becomes a valuable asset later in life.

TobaA startup is a very special experience, but I believe similar opportunities will come again. Even from a global perspective, aluminum demand continues to grow, and there will surely be opportunities for large-scale investment in the future. When that time comes, I hope they will step forward with the mindset that they want to play an active role.

AritaSince I continue to work in Thailand, I increasingly feel that developing local staff will be essential going forward. The members in Rayong are highly capable, and I want to help create an environment where they can demonstrate leadership with confidence. I see that as the baton I can pass on to the next generation.

YamaguchiThe experience of building a factory from an empty site through a greenfield project is not something easily gained. I hope this experience will be put to use in future management and human resource development roles.

I look forward to seeing UACJ continue to take on new challenges that make people think, “UACJ has started something exciting.”

——What kind of future do you envision for the Rayong Works?

KawamotoSustaining change without interruption. I believe that is the most important factor. Maintaining the status quo is the same as moving backward, and without change, equipment ages and customers drift away. This is why I want our current members and the next generation to keep the mindset of taking on new challenges.

GunjiI would be delighted to see Thai staff eventually take on roles such as managing director. A future where locally trained members lead the Rayong Works, I believe that would constitute genuine realization oflocalization.

AritaBefore I knew it, more than ten years had passed since I moved here, and during that time, I built a family and welcomed children into the world. Reaching these milestones was possible because of this company and the Rayong Works. This place has the power to develop and transform people. I hope it will continue serving as a bridge connecting Thailand, Japan, and the next generation.

YamaguchiThe Rayong Works has become a major pillar supporting UACJ Group. However, this is not the goal. I hope the factory continues to take on new products and technologies and achieve progress that surprises people.

I hope the Rayong Works continues to create these kinds of challenge-driven stories.