Passing Down Technology, Empowering people, Shaping the Future — The Challenge at Rayong Works

- HOME

- Aluminum lightens the world

- UACJ Stories

- Passing Down Technology, Empowering people, Shaping the Future — The Challenge at Rayong Works

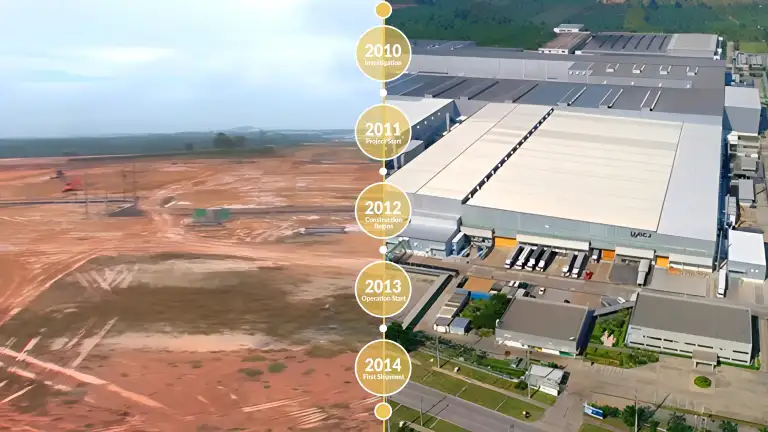

In 2013, UACJ took a new step into the world, with Japan’s manufacturing technologies. Symbolizing this step was the Rayong Works, constructed in Rayong Province, Thailand, as one of the largest flat rolled aluminum factories in Southeast Asia.

The challenge, which began with driving the first stake into an empty plot of land, became a grand project that required building electricity, water, roads, and even human capabilities from the ground up.

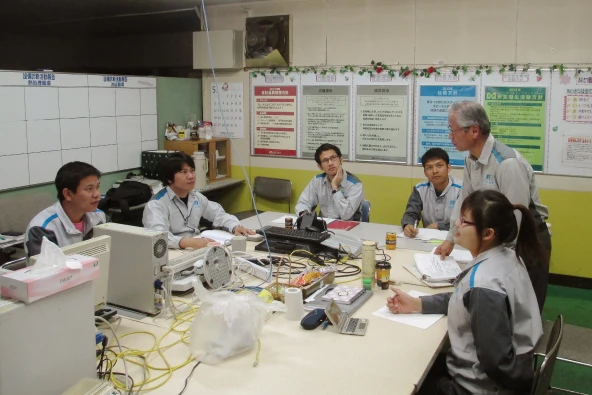

Supporting this journey was the strength of a workplace where Japanese and Thai cultures and technologies intersected. We spoke with four members from different specialized fields, equipment, manufacturing, and interpretation, who have contributed to the development of the Rayong Works, about their experiences during the startup phase and the sentiments that emerged from them.

SPEAKER

Edison Jitpreeda

(Nickname:Nick)

Senior Manager

Mechanical Engineering

Engineering & Maintenance Dept.

UACJ (Thailand) Co., Ltd.

Busaraporn Jarusapanan

(Nickname:Gig)

Deputy Manager

Coating

Production Dept.

UACJ (Thailand) Co., Ltd.

Sayam Chaisa

(Nickname:Sayam)

Production Unit Leader

Cold Rolling

Production Dept.

UACJ (Thailand) Co., Ltd.

Wanalee Kobkhum

(Nickname:Ning)

Administrative Expert (Int.)

Human Resources Management

Administrative Dept.

UACJ (Thailand) Co., Ltd.

Rayong Plant: Starting from Scratch

——Please tell us what motivated you to join UACJ Rayong Works.

NickI originally worked as an engineer at another manufacturing company, but when I heard that UACJ would be constructing a new factory in Thailand, the idea of “starting manufacturing from zero” attracted me, and I decided to join.

SayamWhat prompted me to join was hearing that I could be involved in the launch of UACJ’s new factory. I had always been interested in aluminum materials, and I applied because I thought it would be an opportunity to learn Japanese technology.

GigI previously worked at a company in Ayutthaya, but the 2011 floods caused severe damage, making it difficult to continue operations. At that time, the person who reached out to me was the president of this company. I was drawn to the chance to once again be involved in manufacturing, and decided to take on this new challenge.

NingWhen I heard that a Japanese company would be building a new factory in Rayong, I felt strongly that I wanted to be part of it. I was already interested in Japanese culture and the Japanese language, and I was also attracted to the opportunity to receive training in Japan.

——What was the workplace like during the startup period?

NickI first received training in Japan, then joined the equipment startup at the Rayong Works. My first assignment was installing the cold rolling mill that had been relocated from the Nikko Works.

At first, everything was new to me and I felt confused, but the Japanese engineers taught me carefully. What I learned at the Japanese site still serves as a very valuable experience today.

I also remember being overwhelmed by the scale of the work, as the rolling mill from the Nikko Works was a large-scale machine that had never been introduced in Thailand before.

SayamAfter one year of training, I joined the startup of the Rayong Works, and building a factory from zero with colleagues who had little experience was a major challenge. The commitment to safety and quality that I learned in Japan supported me, and I made sure to share that mindset with the team in Thailand.

GigWhen I first entered the site, there were no factories or offices yet, and we began working inside containers. It truly was a start from zero.

At that time, even the Japanese staff had little experience working with foreign colleagues, so we needed to move forward while understanding each other’s cultural differences. Being able to work cooperatively under such circumstances was a significant experience.

NingI first joined the training in Japan and learned the basic knowledge of aluminum rolling from the ground up. Since I had never worked in the aluminum field before, everything was a new discovery. As an interpreter, I needed to understand the technical content myself in order to communicate it accurately, so I studied the technical aspects as well.

A Decade of Progress Together with Rayong

——Were there any memorable episodes during the process of inheriting Japanese technologies?

NickAluminum manufacturing involves many manual operations, and it was difficult to understand the mechanisms. At such times, what left a strong impression on me was how the Japanese staff explained everything step by step while drawing diagrams.

In the training in Japan, I learned not only the technologies but also the care taken to communicate things accurately and the attitude toward teaching. That experience greatly supported me when I returned to Thailand for the equipment startup.

SayamWhen I received training in Japan, the first thing that surprised me was the control panel of the equipment. It was much larger than the ones we handled in Thailand, and it had nearly 100 buttons. It made me anxious about being able to remember all operation.

However the Japanese staffs reassured me that we don't use everything at once and that I only needed to understand the operations required for each process. Their teaching was very thorough, and as I learned while operating the equipment myself, I naturally came to understand it.

Today, the equipment has been improved to be more user-friendly, but I feel that the experience from that time is still being applied.

NingWhat left the strongest impression on me during the training in Japan was the “attitude toward teaching” of the Japanese staff. Even with the language barrier, they drew diagrams and explained things while actually operating equipment on site so that we could understand, and they taught us with great care. Seeing their dedication motivated me to adopt the same approach in how I communicate with others.

I believe that I am who I am today because of that experience, and I remain sincerely grateful to the people in Japan who taught me.

——As a member of the startup team, what was the most challenging task?

NickThe most difficult task was organizing the initial work processes. However, the approach I learned during training in Japan, which emphasized planning while observing the site directly, was extremely helpful.

Building on my own experience and what I learned in Japan has become a major foundation for me when instructing junior members and new employees today.

SayamThe most difficult task was teaching local staffs how to operate the aluminum rolling mill. There were many components and processes, so we had to start by helping them learn the names and mechanisms. With limited time and the need for them to master everything including safety related matters, it felt like a constant race against time.

I applied the teaching methods I learned in Japan and continually sought better ways to train them. When they eventually began guiding their own junior colleagues, it was tremendously rewarding. I remain grateful to the Japanese staff and interpreter colleagues who supported us.

GigThe most challenging period was the test run. Unexpected adjustments continued until the large-scale equipment became stable, but I believe we overcame it by supporting one another as a Japanese–Thai team. That is why the moment the first coil was completed felt so special.

NingThe most difficult part was dealing with unexpected issues during the test run. Listening and conveying information in conditions such as high places, confined spaces, and loud noise was far more intense than I had imagined. I am grateful to the advisors who helped me overcome the language barrier and support smooth communication. The moment we completed the first coil is something I still remember clearly.

——Over more than ten years with the company, what notable moments stand out to you?

NickOne memorable moment was when a small fire occurred while operating the equipment. Fortunately, it did not lead to major damage, but it prompted me to reconsider the equipment structure and our safety measures. It was a difficult experience, but I believe it strengthened my awareness of always prioritizing safety.

SayamMy fondest memory is the warmth of the hospitality I experienced during training in Japan. Not only did they provide guidance on site, but they also supported me kindly in daily life and meals. Thanks to them, I was able to focus on my training without worry.

On days off, they even took us skiing. Since we do not see snow in Thailand, it was truly refreshing. I still remember the scenery clearly. Experiences like those, beyond work, became an important opportunity to learn about Japanese culture.

GigMy strongest memories also come from training in Japan. On days off, I was able to experience Japanese culture firsthand by attending fireworks festivals, visiting shrines, and even participating in the Mikuni Festival in Fukui. I also ran in a marathon event, and the time outside of work was incredibly enjoyable.

NingMy most memorable experiences also come from the time I trained in Japan. On weekends, Japanese staff took us to different places, and I will never forget the impact of riding the roller coaster at an amusement park. It felt like I experienced a lifetime’s worth of thrill in a single ride.

After returning to Thailand, it became our turn to welcome staff arriving from Japan, and our relationships deepened beyond just work. Being able to serve as a bridge between the two countries as an interpreter remains a great source of pride for me.

——How did you overcome the differences in culture and ways of thinking between Japanese and Thai staff?

NickIn Thailand, the common approach is to “try first,” so the attitude I learned in Japan of “confirm before proceeding” was a major realization. At first, the differences in values were confusing, but through continuous discussions, we came to understand each other’s perspectives, and the awareness of protecting safety and quality became firmly rooted within me.

SayamDuring training in Japan, I was struck by how thoroughly they prepared to prevent accidents and by the attitude of never overlooking even small mistakes.

While that awareness is not yet fully established in Thailand, I want to apply the safety mindset I learned in Japan to make the Rayong Works an even safer workplace.

What the Rayong Team Wants to Pass on to the Next Generation

——What would you like to pass on to the next generation?

NickIn any kind of work, establishing a solid plan at the beginning is the most important step. With a good plan, 80% of the success is already determined. When you build a strong foundation, you can take on any challenge with confidence. That is the “fundamental approach to work” I want to pass on to the next generation.

SayamWhat I want to pass on is the three values stated in the UACJ Group Philosophy. The first is “Respect and understand your associates,” the second is “Embrace honesty and foresight,” and the last is “Be curious and challenging.”

If you keep these three values in mind, you will be able to do great work. I hope the next generation will join us in building a UACJ that is trusted not only in Japan and Thailand but around the world.

GigWhat I want to emphasize is the importance of taking pride in being a member of UACJ. The company’s philosophy and mission are truly meaningful, and by working with those in mind, you will also certainly grow as an individual.

I hope the next generation will work with confidence and pride to make the future of UACJ even better.

NingWhat I have learned through this work is the value of ongoing learning. By not only handling Japanese as an interpreter but also understanding aluminum rolling technology and manufacturing processes, I became able to communicate more accurately and confidently.

I hope the next generation will continue to absorb knowledge and skills, take pride in being part of UACJ, and carry forward manufacturing that leads to the future.

——What kind of Rayong Works do you hope to build in the future?

NickFrom here on, I want us to aim for a more environmentally friendly factory. By advancing aluminum recycling and reuse, and improving energy efficiency, we can achieve sustainable production.

I hope we can grow into a facility that contributes to the community as a “factory that is friendly to both the environment and people.”

SayamI want to further strengthen an environmentally conscious production structure by leveraging our aluminum rolling technologies. By growing together with the local community, I hope people will say, “UACJ is a company you can trust,” and I want to expand it from Asia to the world.

GigI want to make the Rayong Works a “place of learning” where aluminum technologies can be studied. It would be wonderful if students and younger generations could visit and learn about our technologies and environmental initiatives. I also want the Thai staff to continue leading our growth and for this site to develop into a core base supporting the entire Group.

NingI want it to remain a workplace where employees can feel a strong sense of satisfaction in being part of UACJ. I want it to be a company where every employee takes pride in their role and supports one another with a warm spirit.

Having been supported by many colleagues, I want us to build a future where being part of UACJ is a shared source of pride.