Performance by Region Japan

Achieving Larger-than-Planned Integration Effects Thanks to Construction of Optimal Production Network through Reallocation of Product Mix

Director, Member of the Board Managing Executive Officer Chief Executive, Production Division

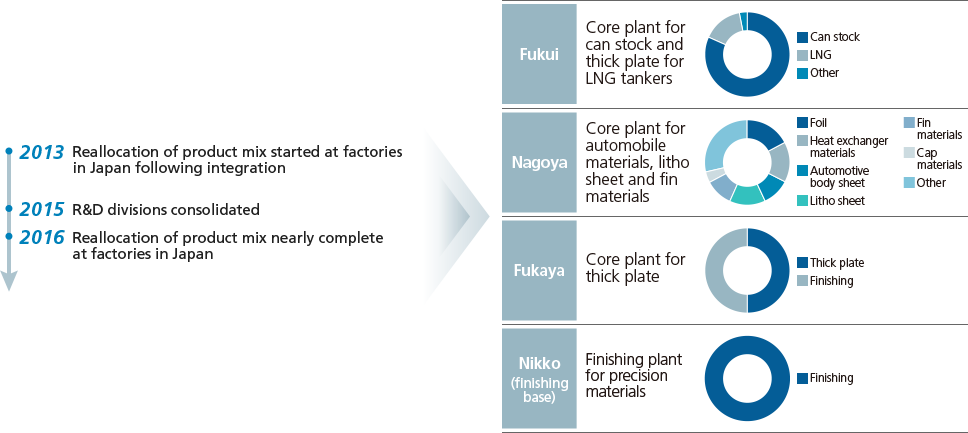

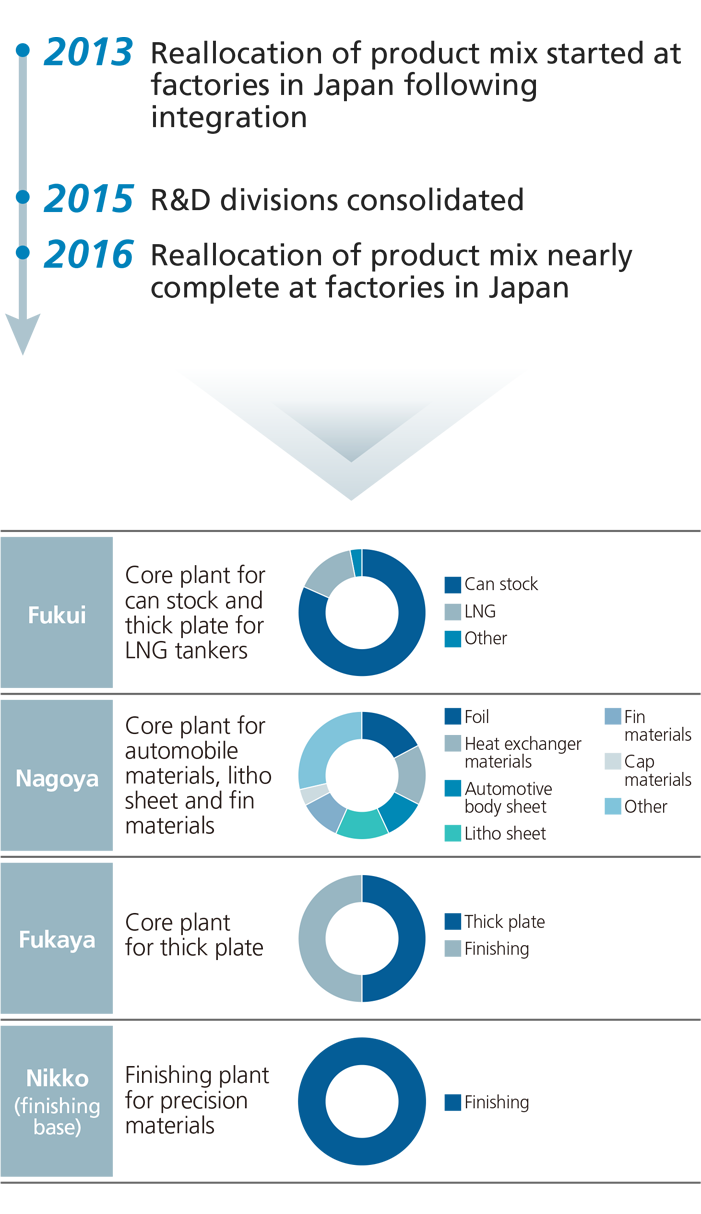

Since integrating operations, UACJ has been pressing forward with reallocating its product mix among its four factories in Japan. Instead of producing the same types of products at each of the former two companies’ factories, we have established a more efficient production network by concentrating on products that take advantage of the features of individual plants. This task was completed in fiscal 2016. As a result, cumulative integration effects totaled 11 billion yen at the end of fiscal 2016, exceeding our initial estimate of 10 billion yen.

The domestic sales volume of our mainstay product, can stock, fell slightly in fiscal 2016. However, an increase in the demand for automotive materials and thick plate for liquid-crystal and semiconductor production equipment more than offset the negative impact, leading to overall domestic sales volume surpassing the previous fiscal year level.

As demand is expected to continue to grow, mainly for automotive materials, the plan is to establish a production system that can handle such changes.

Fiscal 2016 Highlights

- Mainstay can stock demand remained solid

- Sales volume of automotive materials and thick plate for liquid-crystal and semiconductor production equipment increased

- Total shipment volume of extruded products posted first year-on-year increase in three years

- Reallocation of product mix among four Japanese factories nearly complete

- Construction of optimal production network led to integration effects amounting to 11 billion yen

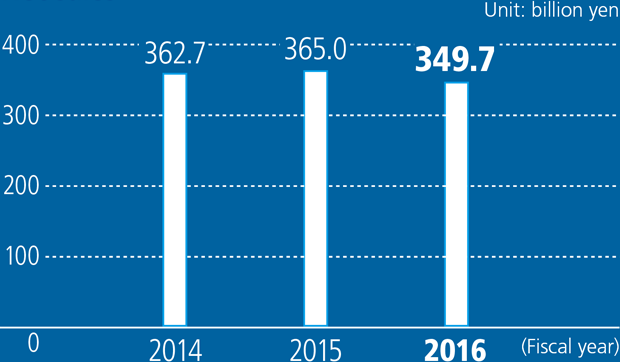

Net sales

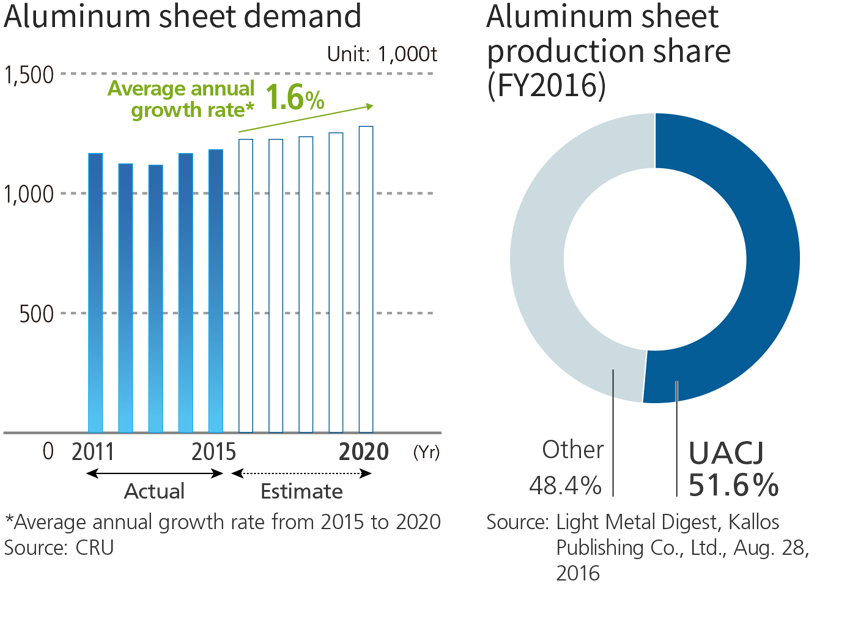

Regional Activity Responding to Brisk Demand by Leveraging Overwhelming Production Share

Although a shrinking market is a cause for concern as the Japanese population declines, demand is expected to increase UACJ’s major market, beverage cans, in particular, low-alcohol beverages and bottle-shaped cans. Meanwhile, as for the automotive industry, a shift towards the use of aluminum is gathering momentum in Japan and the rest of the world. Consequently, demand is on the rise for aluminum body sheet. The greatest strength of UACJ in the Japanese market is a high share of more than 50% of total production volume. On the back of this unparalleled scale, UACJ will focus on steadily capturing demand, mainly in growth areas, by demonstrating its overwhelming competitive edge in the Japanese market.

Accumulated Improvement in Network and ESG Activities

Building an optimal production network that utilizes the features of each plant

ESG Activity 1Putting Systems in Place to Improve Work Environment and Take Advantage of Diversity

The Act on Promotion of Women’s Participation and Advancement in the Workplace was enacted in Japan in August 2015, and women’s work styles began attracting increasingly more attention. UACJ is working to expand opportunities for women by setting specific numerical targets based on action plans set forth under the aforementioned law. For example, “Ensuring 40% of the new college graduates we hire into administrative positions are women and hiring women for at least 10% of technical positions,” and “Doubling the number of women in management positions based on the number in March 2016.” Furthermore, childcare leave and a re-employment system are in place, and a teleworking scheme has been newly introduced. We are working to establish systems that ensure an excellent working environment for every employee, regardless of their gender or age, and publicizing the systems so that more employees will take advantage of them. In order to achieve one of the targets set forth in the Global Step I Mid-term Management Plan, “Practice diversity,” we are creating work

environments in which more diverse ways of working are possible.

ESG Activity 2Promoting Passing Down of Skills That Improve Onsite Performance

At UACJ, a majority of the experienced and skilled workforce that participated in the startup of our plants in Japan will retire within 10 years from now. We regard it as an important issue to pass down technologies, expertise and ethos that have been developed over many years to the next generation in order to maintain our competitive edge as a manufacturer. Therefore, we proactively provide opportunities to hand down skills to subordinate personnel. For instance, a course was launched at the Nagoya Works featuring skilled veterans in the areas of plate making, extrusion, and copper working as the lecturers. In 2016, we also established a course at the Fukui Works. Additionally, retired employees are rehired to pass down the skills and knowledge of specialized processes to the entire line, including the experiences of high value-added manufacturing from the customer’s perspective.

- Performance by Business

- Performance by Region