Performance by Region USA

Increasing Can Stock Supply Capacity While Proactively

Responding to Rise in Aluminum Demand for Automobiles

CEO/President

Tri-Arrows Aluminum Inc.

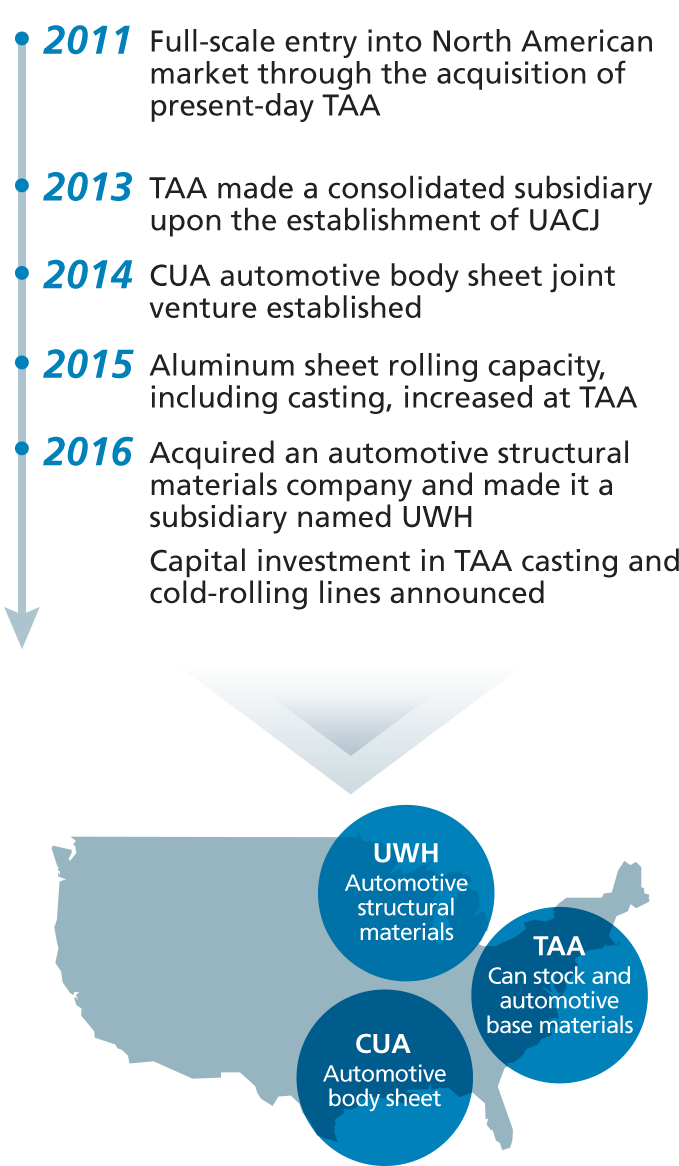

UACJ made a full-scale entry into the American market by acquiring present-day TAA in 2011. The Logan Mill operated by TAA has established itself as the can stock plant with the world’s highest production efficiency. It also began supplying base materials for automotive body sheet manufactured by CUA.

In order to keep pace with increasing demand, CUA started sample shipments and sales of automotive materials in June 2016. For structural materials, too, in April 2016 UACJ acquired a leading company of automotive structural materials and parts known for its Whitehall brand and made it a subsidiary named UWH. UACJ has therefore advanced its efforts to build a network capable of handling the rising demand. At TAA, while reinforcing the supply network for base materials to CUA, it was decided to make an additional investment in November 2016 in order to boost the plant’s can stock supply capacity amidst concerns of a supply shortage. In the future, we will proactively capture business opportunities centering on these three companies.

Fiscal 2016 Highlights

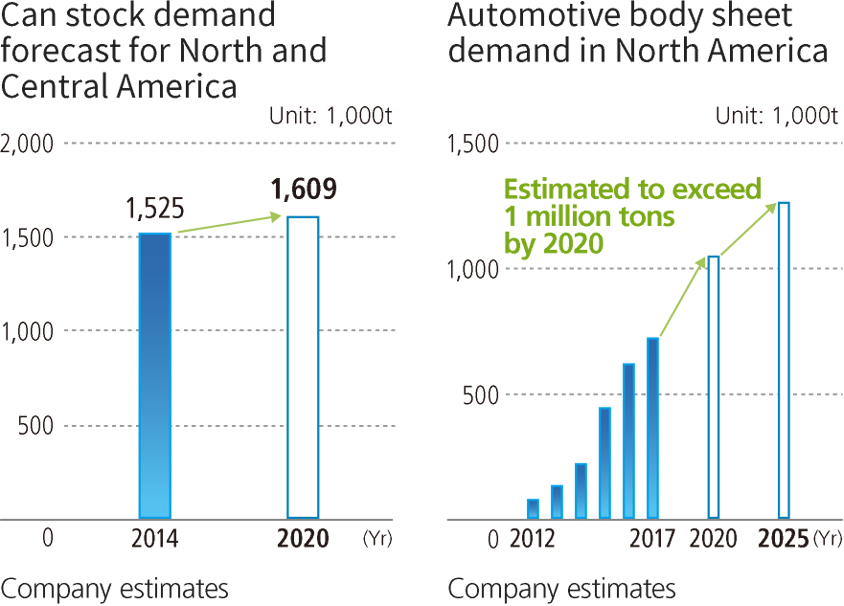

- Automotive body sheet demand increased for lighter cars

- Can stock manufacturers also shifted their focus to automotive materials, creating concern of a shortage in can stock supply

- CUA began sample shipments and sales of automotive body sheet

- Acquired a leading company in the North American automotive structural materials industry and made it a subsidiary named UWH

- Committed 175 million dollar investment given in the casting and cold rolling lines of TAA to raise its annual production capacity to 400,000 tons

CUA:Constellium-UACJ ABS LLC

UWH:UACJ Automotive Whitehall Industries, Inc.

TAA:Tri-Arrows Aluminum Inc.

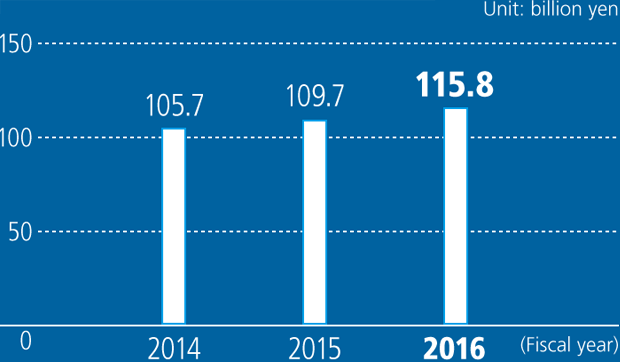

Net sales

Regional ActivityCapturing Growth Opportunities While Keeping an Eye on Increasing Demand for Automotive Materials and the Concern of Can Stock Shortage

In the US aluminum market, aluminum is being used for more automotive parts as part of the effort to reduce overall automobile weight. Amidst this trend, the global manufacturers of can stock are shifting their focus on production towards automotive materials. In the meantime, as the U.S. market is also the world’s largest can stock consumption region, with demand expected to remain solid, concerns are emerging that there may be a shortage of can stock. UACJ considers the demand trends in automotive materials and can stock as growth opportunities, and is planning to respond proactively. While TAA has established itself as a leading supplier of can stock, it also has the role of supply base for base materials used to produce automotive body sheet. The capital investment plan given the go-ahead in November 2016 should help TAA expand its base materials supply volume, while maintaining its responsibility to provide can stock.

Accumulated Improvement in Network and ESG Activities

Three-company network for handling can

stock and automotive materials demand

ESG Activity 1Synergies Generated by Taking Advantage of Diverse Knowledge

UACJ has expanded its business by incorporating external forces into the Group in North America via TAA, launching the joint venture CUA, and purchasing what is now UWH. These developments have led to a situation in which individuals from diverse backgrounds—which was not the case previously at UACJ—work together. This, in turn, has produced various wide-ranging synergies. For example, by supplying CUA with base materials, TAA has obtained expertise in automotive materials in addition to its traditional know-how in can manufacturing. Additionally, acquiring the company now known as UWH led to introducing that organization’s manufacturing expertise to the Group, in addition to a vast amount of marketing data that was accumulated and is now being in R&D by the Group as a whole. We believe that such synergies are further enhancing our global competitive edge.

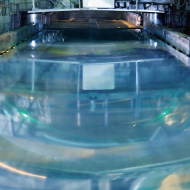

ESG Activity 2Recycling Ratio Also Improved by Increasing the Number of Casting Lines

In the USA, one of the world’s largest can consumption countries, recycling is thriving, with a reported 127,000 cans recycled every minute. At TAA, too, active efforts are being made to increase recycling and reduce environmental load. Approximately 80% of the raw materials used for can stock at the Logan Mill is recycled aluminum. In addition to reusing scrap aluminum generated at the factory, TAA also accepts it from external sources. Logan Mill’s state-of-the-art casting furnace enables these advanced recycling efforts. The capital expenditure plan announced in November 2016 will help increase production capabilities and improve the recycling ratio even further.

- Performance by Business

- Performance by Region