Special FeatureJapan

Transferring skills and providing solutions while expanding the supply of high-demand automotive body sheet

Mizuho Taneoka

Representative Director, Member of the Board,

Senior Managing Executive Officer

Market trends

- North American initiatives for reducing vehicle weight have spread to Japan

- The market for liquid crystal panel and semiconductor manufacturing equipment was brisk due to strong sales of tablet computers and other IT-related devices

- IoT and AI were increasingly applied at factories

- A shortage of factory workers became an increasingly urgent issue

The UACJ Group’s recent activities

Bolstering production capacity of automotive materials while supplying products to a wide range of industries

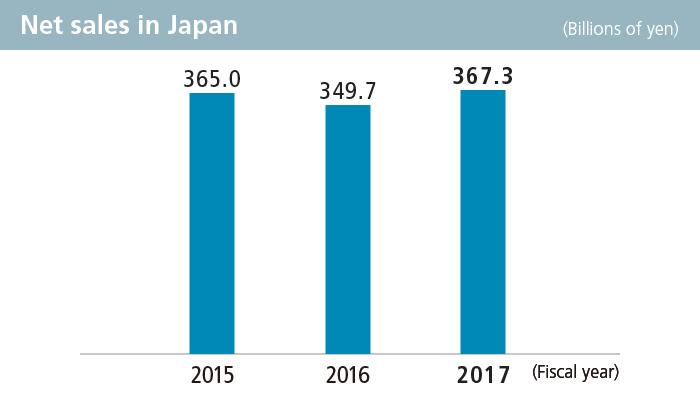

In Japan, UACJ supplies aluminum products to meet the diverse needs of a wide range of industries, including aluminum for beverage cans, automobiles, aircraft, ships, IT-related devices and equipment, and building materials. In each of these markets, demand for aluminum is projected to remain strong in the future. For example, in the beverage can market, of which UACJ holds an unrivalled share of around 50%, can stock demand is forecast to grow even more, especially for low-alcohol beverage cans and bottle-shaped cans for coffee and other types of drinks. Moreover, due to the popularity of smartphones and table computers, solid demand is expected for aluminum materials used to make device casings as well as liquid crystal and semiconductor manufacturing equipment.

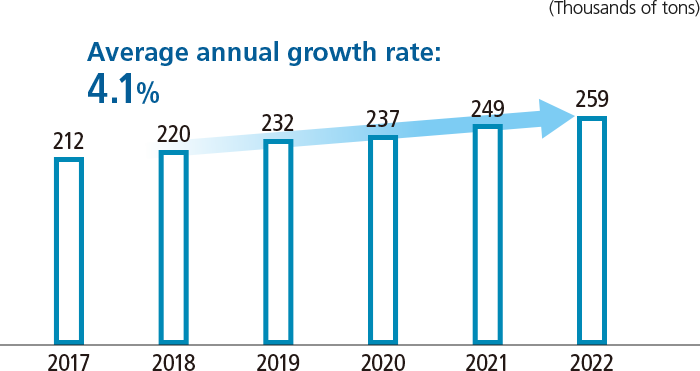

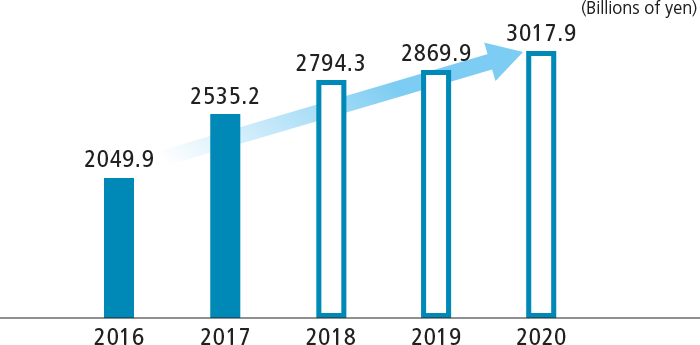

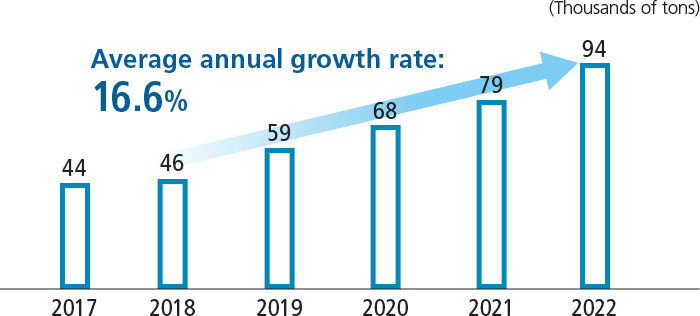

Demand for aluminum automotive materials in particular is projected to rise, driven by initiatives originating in North America for reducing the weight of automobiles. This trend has also reached Japan, where demand for automotive body sheet and other aluminum components is gaining momentum. In response, UACJ added new facilities at Fukui Works for manufacturing automotive body sheet and materials, supplementing production of these products already handled by Nagoya Works, which also manufactures heat exchanger materials. With operations scheduled to commence in 2020, production capacity in Japan is set to reach approximately 100,000 tons.

Management tasks

Training programs launched to transfer skills at all manufacturing plants

Transferring skills is our biggest task at manufacturing plants in Japan. Many of UACJ’s engineers who had been involved in starting up manufacturing operations in Japan will retire over the next decade. Therefore, having them pass down the production techniques, know-how, and broad expertise they gained over many years to younger employees will be essential for the Company to maintain its competitive edge as a manufacturer.

With that in mind, we are now creating training opportunities at each production plant in Japan. At Nagoya Works, for instance, engineers are learning about high-added-value production in an in-depth technical training program led by experienced technical staff from various departments as well as retired engineers who have been rehired. Opportunities to learn skills have also begun at Fukui Works. The training includes instructions on starting up manufacturing facilities, particularly the new automotive body sheet heat treatment line scheduled to begin operating in 2020.

By teaching younger employees people about the manufacturing techniques and expertise accumulated at UACJ through these programs, we hope to maintain and improve the Company's competitiveness while also contributing to the competitiveness of Japan's manufacturing industry and preserving the human assets it has developed.

Fiscal 2017 highlights

- Decision made to install a new automotive body sheet heat treatment line at Fukui Works to meet growing demand

- State-of-the-art extrusion equipment was installed at UACJ Extrusion Nagoya Corporation’s automotive parts manufacturing facilities

- Workplace reform projects commenced