Special FeatureAsia

Focusing on training workers needed for industrial progress amid economic growth and rising demand

Hironori Tsuchiya

President and director

UACJ (Thailand) Co., Ltd.

Market trends

- Demand for beverage cans rose on the back of economic growth

- The shift to electric vehicles accelerated following stricter environmental regulations for automobiles in China, boosting orders to heat exchanger manufacturers

- The Thai government positioned the manufacturing sector as the driver of economic development and stepped up support

- Training workers and transferring skills in manufacturing industries has emerged as a major challenge

The UACJ Group's recent activities

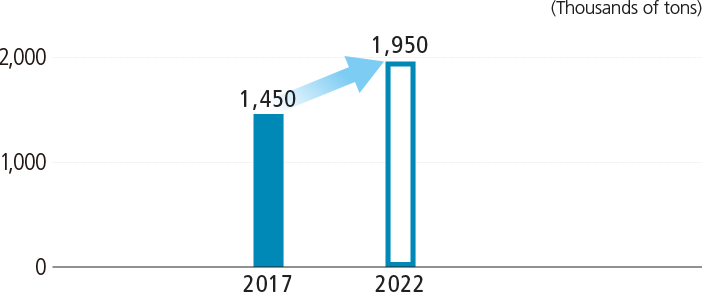

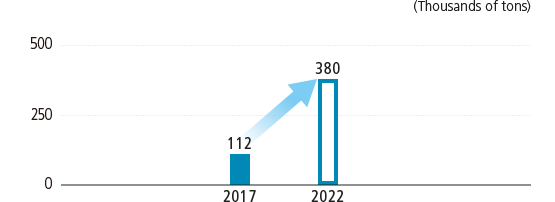

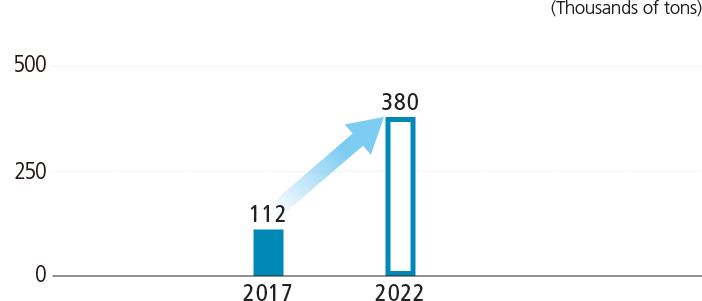

Meeting growing demand by boosting production capacity to 320,000 tons at Southeast Asia’s only comprehensive flat-rolled aluminum factory

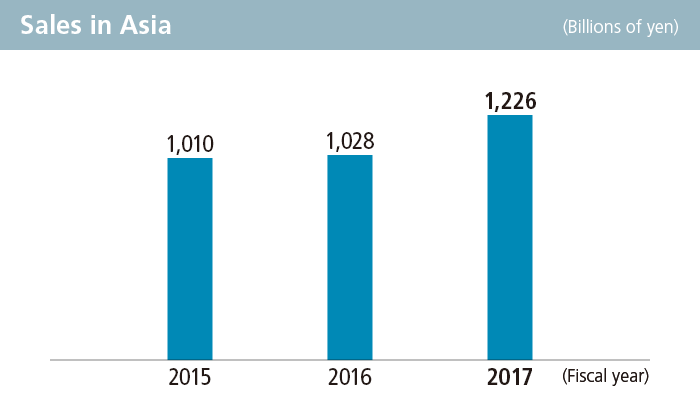

In Southeast Asia, the population has been increasing along with economic growth and consumer spending is on the rise. Consequently, demand for aluminum for beverage cans, automobiles and other products continues to grow. To meet this growing demand, UACJ (Thailand) Co., Ltd., has been constructing and expanding Rayong Works— Southeast Asia’s only flat-rolled aluminum factory integrating melting, casting, hot and cold rolling and finishing lines —since fiscal 2012. Rayong Works has mainly been manufacturing aluminum can stock and heat exchanger materials since the completion of its second phase of construction in 2016, which increased annual production capacity to 180,000 tons, among the highest in Asia. In addition to supplying products to Thailand’s beverage can market and auto parts factories, UACJ (Thailand) has expanded its customer base from Asia to Australia and Middle Eastern countries, contributing to Thailand’s growing exports of aluminum products.

In anticipation of rising demand in the future, UACJ plans to increase investment in Rayong Works with a view to boosting production capacity to 320,000 tons, which is about the same as Nagoya Works and Fukui Works, respectively. Despite that unrivalled capacity, however, cost competition is heating up in the region due to the recent entry of aluminum manufacturers from other Asian countries, including China and South Korea. Therefore, UACJ (Thailand) is striving to broaden its sales channels while giving priority to cost competitiveness going forward.

Management tasks

Transferring skills from experienced Japanese engineers to raise skill levels of local personnel

Training local personnel has been a big project at Rayong Works ever since it began operating. Improving the level of their skills not only raises our productivity, but also fosters the human resources that will lead Thailand’s industrial sector in the future. Therefore, from the time Rayong Works was under construction, we appointed experienced engineers from Japan to pass on their skills to our Thai personnel. The engineers have set up a system for ongoing training, compiling standardized manuals detailing each specific operation in manufacturing areas, explaining working objectives and procedures, and conducting on-the-job training when operations start up. As a result of this initiative and the installation of automated equipment, our Thai engineers and workers employed for only two or three years can now handle all of the plant's manufacturing operations, which would normally require about 10 years.

While aiming to make the company profitable by fiscal 2019, we will continue focusing on training in order to enhance the skills of our Thai employees so they can to take over the remaining duties currently handled by Japanese staff, such as maintaining facilities and operating production lines when facilities are expanded.

Fiscal 2017 highlights

- Sales volume of flat-rolled aluminum for can stock increased substantially, reflecting population growth

- Sales of heat exchanger materials were strong on the back of rising demand for automobiles

- Average monthly production output reached 10,000 tons at Rayong Works as local personnel improved their skills