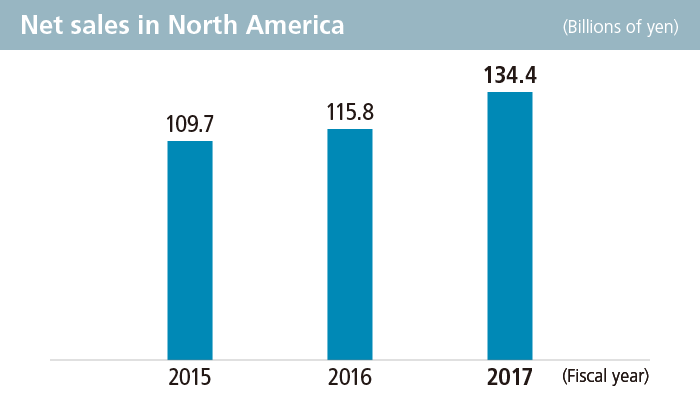

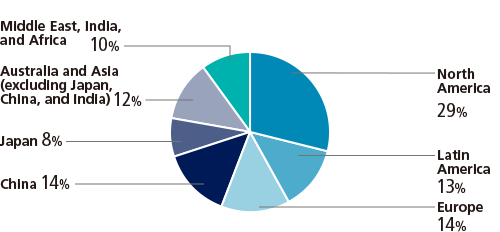

Special FeatureNorth America

Responding to concerns over supply in the world's largest can stock market and automakers' efforts to comply with tougher environmental regulations

Henry Gordinier

President and CEO

Tri-Arrows Aluminum Inc.

Market trends

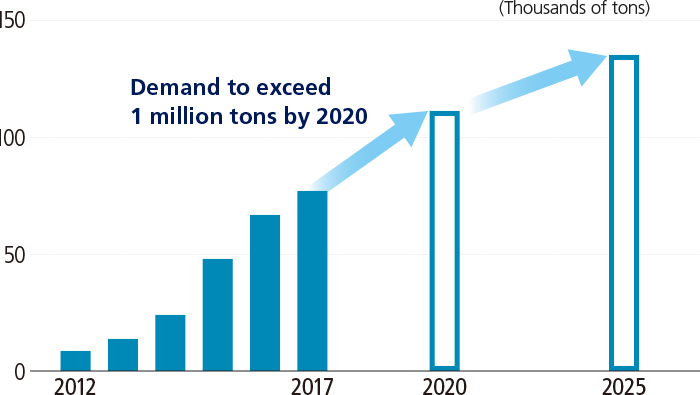

- The shift to electric vehicles and more lightweight cars accelerated due to stricter environmental regulations

- Beverage can demand stabilized in North America, the world’s largest market

- Flat-rolled aluminum manufacturers shifted from can stock to automotive materials

The UACJ Group's

recent activities

Leveraging increased production capacity to meet demand for both automotive materials and can stock

Amid increasingly strict environmental regulations in the automotive industry, automakers are proactively adopting aluminum as a material for reducing vehicle weight. In response, UACJ has laid the foundations for its automotive materials business in the North American market. Three group companies are now systematically working together to meet brisk demand: automotive body sheet manufacturer Constellium-UACJ ABS LLC, automotive structural material manufacturer UACJ Automotive Whitehall Industries, Inc., and Tri-Arrows Aluminum Inc., which supplies structural materials produced at its Logan Mill.

In 2017, Logan Mill began operating a new melting and casting line for scrap aluminum, thereby raising its cost competitiveness. In the same year, UACJ Automotive Whitehall's factory became the first in North America to install a state-of-the-art HybrEx extrusion press, enabling it to ensure high quality and supply products at a lower cost.

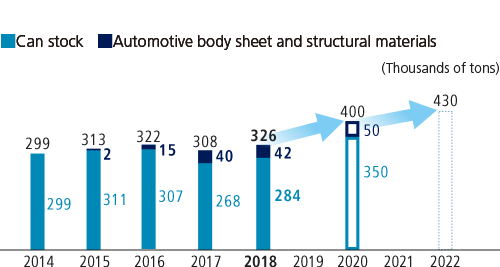

North America is the world’s largest market for canned beverages, consuming approximately 94 billion aluminum cans annually. Maintaining a stable supply of can stock, however, is a growing concern because flat-rolled aluminum manufacturers have been shifting production from can stock to automotive materials in recent years to meet rising demand from the automotive industry. In response to that major trend, UACJ plans to boost production capacity at Logan Mill in order to increase its supply of flat-rolled aluminum for both automotive materials and can stock. Annual production at the mill is scheduled to reach 400,000 tons by fiscal 2020, comprised of 350,000 tons of can stock and 50,000 tons of automotive materials.

In addition to boosting production capacity through these initiatives, UACJ established a new R&D center in Chicago, Illinois, in April 2018. As the Group’s first research and development facility outside Japan, the center will facilitate speedier product development and more precisely target demand for automotive materials and other products in the North American market.

Management tasks

Focusing on key issues at each factory in order to take advantage of increased production capacity

As UACJ continues to invest in greater production capacity of its operations around the world, it is necessary to ensure that new manufacturing equipment operates according to plans at each factory. At Logan Mill, for example, our job is to raise the efficiency of production. The mill’s efficiency was among the world’s best when it specialized exclusively in producing can stock, but manufacturing has become more complicated now that it has begun supplying automotive body sheet and structural materials, so we need to make production techniques more precise than ever before. At Constellium-UACJ, we will dispatch expert teams that specialize in raising productivity to help improve the skill levels of its operators, and are working to make this company profitable as soon as possible. By overcoming these challenges, we look forward to leveraging our world-class efficiency to meet demand for can stock as well as rapidly growing demand for aluminum automotive materials.

Fiscal 2017 highlights

- A new melting and casting line for scrap aluminum began operating at Tri-Arrows Aluminum's Logan Mill

- Aluminum extrusion subsidiary UACJ Automotive Whitehall Industries became the first company in North America to equip its parts production lines with a new HybrEx extrusion press

- A new R&D center was established in the U.S. in April 2014 as the Group’s first R&D facility outside Japan