Aluminum is our passion. It inspires our work in building a better world and a healthier environment.

Changes in the global environment represent a major issue directly linked to corporate activities.

Climate change, resource constraints, and waste problems undermine the sustainability of society as a whole while simultaneously posing major risks to industry.

UACJ, for "passing down a 'Lighter World' over the next century," will continue to reduce environmental impact and contribute to a sustainable society through aluminum by bringing together the skills and expertise that we have cultivated over many years.

- 01A world-leading

"comprehensive aluminum manufacturer" - 02UACJ's manufacturing

capability and R&D strength - 03Aluminum that contributes

to a sustainable society

01A world-leading

"comprehensive aluminum

manufacturer" that creates a "lighter world"

A global top-class company in rolled aluminum products

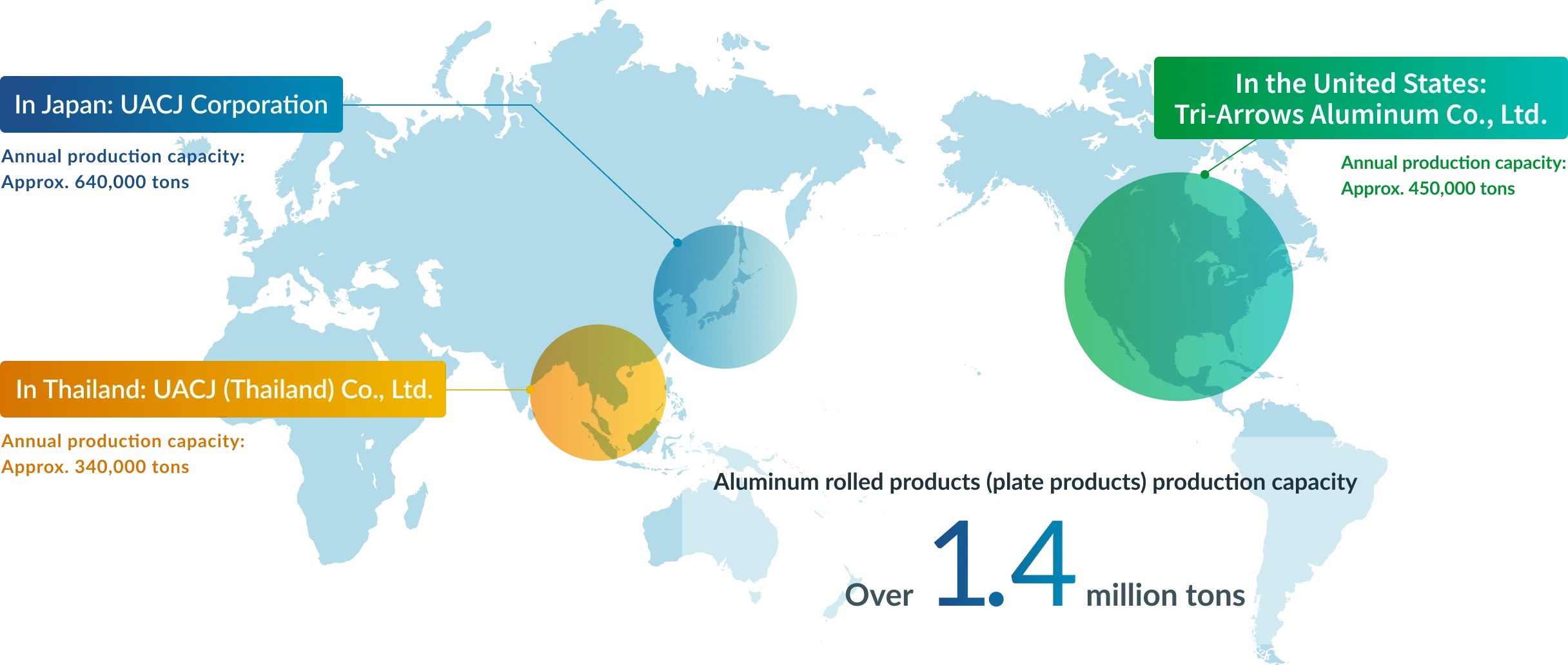

UACJ was established in October 2013 through the management integration of Furukawa-Sky Aluminum Corp. and Sumitomo Light Metal Industries, Ltd . By uniting two leading Japanese aluminum manufacturers, each with a history of over 100 years and outstanding track records, annual production capacity for rolled aluminum products (plate products) now exceeds 1.4 million tons, giving birth to a Japan-origin comprehensive aluminum manufacturer capable of competing in the global market.

We have built a global supply system centered on Japan, North America, and Thailand. In Japan, we have established an optimal production system at our three core aluminum sheet manufacturing sites—Nagoya, Fukui, and Fukaya—enabling efficient supply of a wide range of products. In North America, centered on the Logan Mill, which boasts the world’s highest level of can stock production efficiency, we supply high-quality products to meet market needs. Meanwhile, in Thailand, we leverage the only fully integrated sheet rolling production system in Southeast Asia so as to respond to growing demand for can stock and heat exchanger materials for automobiles and air conditioners, accompanying economic expansion. Through stable global supply, we lead the aluminum market.

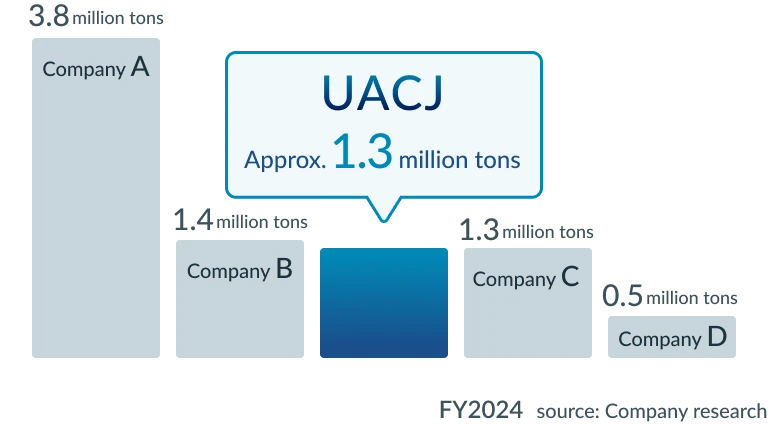

Global rolled aluminum producers ranked by annual sales volume (April 1, 2024, to March 31, 2025)

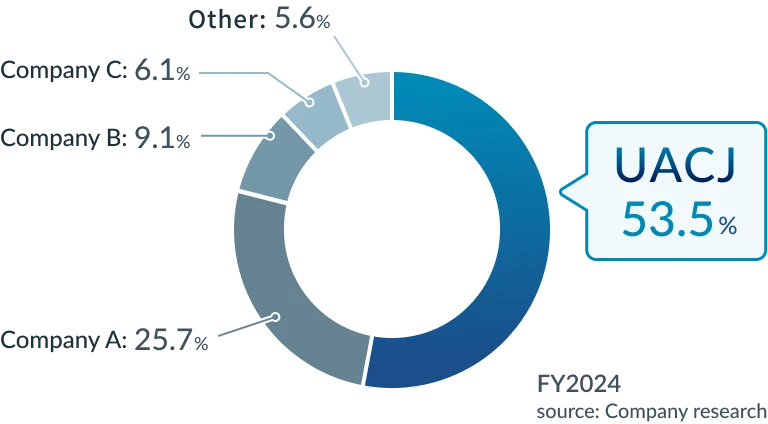

Market share (Japan)

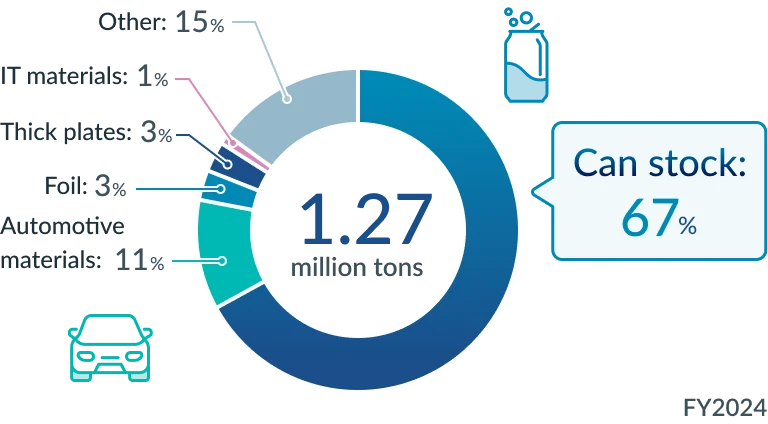

Aluminum flat rolled sheet and plate sales volume

Establishing a global production system

As a comprehensive aluminum manufacturer, serving a wide range of industrial fields

From aluminum plates and extrusions to foil, and cast and forged products, we have accumulated extensive knowledge of aluminum, advanced technologies, and abundant know-how. By leveraging these strengths, we reliably supply high-quality products and contribute to the development of various industrial fields.

UACJ conducts automotive parts business and aerospace & defense materials business. Leveraging advanced technology and know-how as cultivated through aluminum manufacturing, we contribute to weight reduction, the shift to electric vehicles, and thermal management in the automotive field through lightweight yet high-strength parts, while in the aerospace field we supply large products that combine high quality and reliability.

As a comprehensive aluminum manufacturer, we meet the needs of a wide range of industrial fields.

Bumpers(automotive parts business)

©︎JAXA

Large forged rings(aerospace & defense materials business)

02UACJ's manufacturing and research & development capabilities that masteraluminum and contribute to a sustainable society

World-class facilities and technology supporting a sustainable society

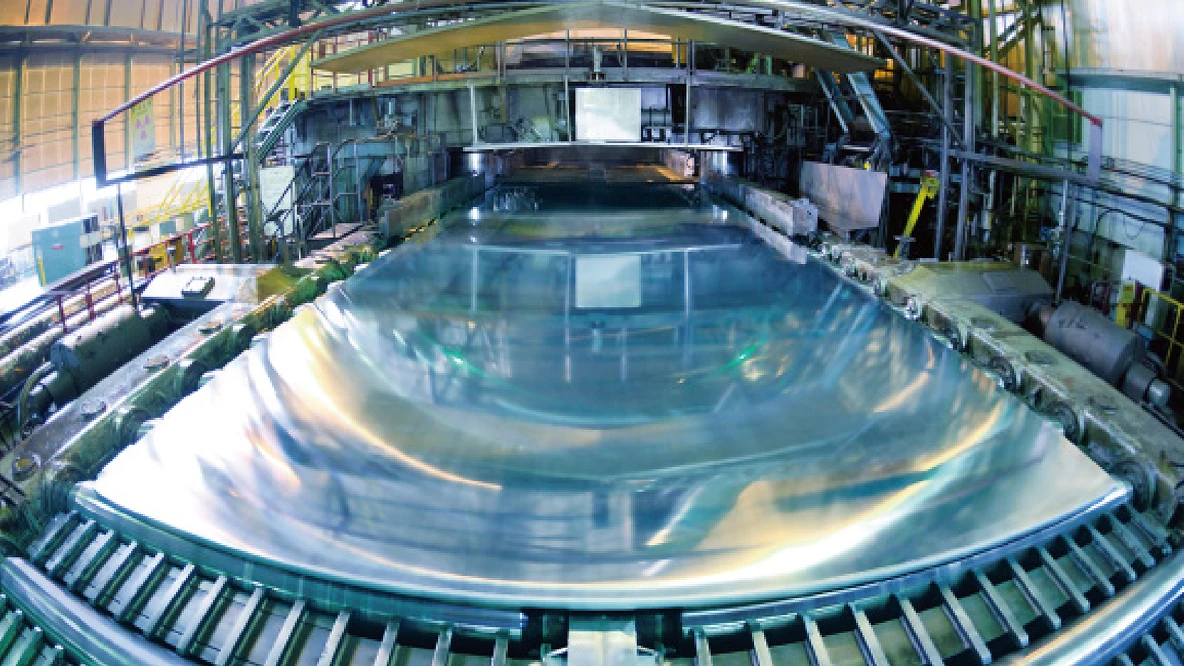

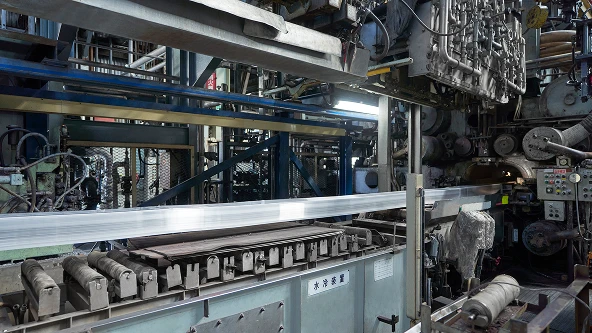

One of the manufacturing facilities that UACJ is most proud of is one of the world's largest mills for hot-rolling, for 400 meters in length and 4.3 meters in width. Other facilities include a four-stand hot rolling finishing mill that can reduce 30 mm thick aluminum to approximately 2 mm in a single roll, along with a six-high cold rolling mill that boasts world-class speed and precision.

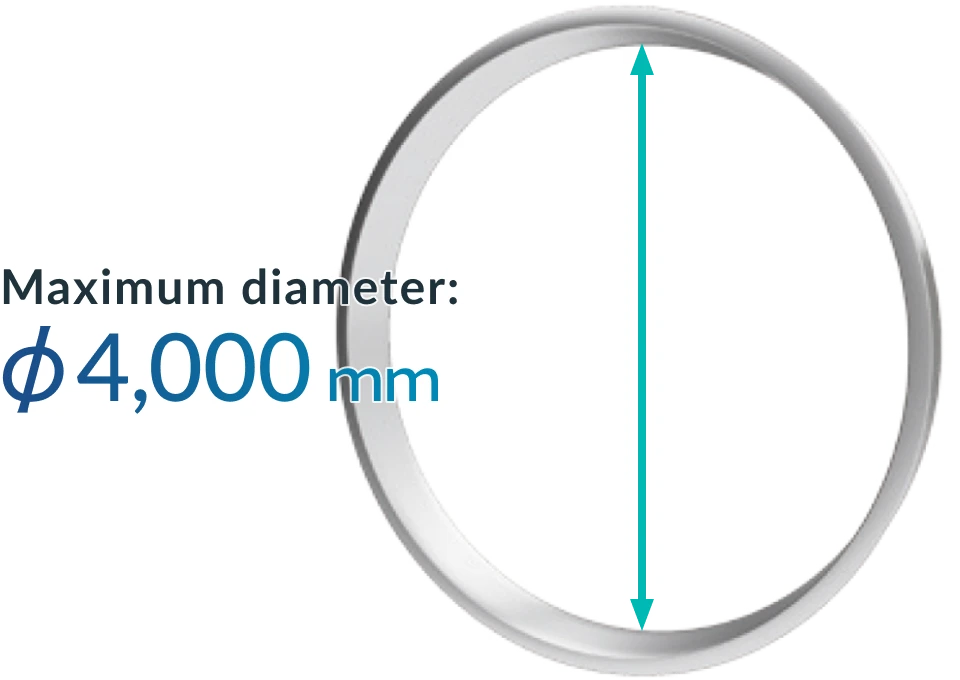

In forging, we manufacture high-speed railway axles, aircraft fuselage frames, large rocket rings with distortion reduced to the utmost limit, and supercharger fans for ships using aluminum alloys that boast the highest strength. We possess one of Asia’s largest 15,000-ton forging presses capable of producing forged products with a maximum mass of 6 tons, thereby meeting customer requirements. In extrusion, in addition to the latest direct extrusion presses, we own multiple large-class 5,600-ton extrusion presses in Japan as well as indirect extrusion presses suited for high-strength materials, maintaining a complete production system.

By utilizing these highly productive facilities, we are able to provide our customers with large-scale, high-quality products that are unique to our company.

One of the World’sLargest Hot-rolling Line

Asia’s Largest-classAluminum Forging Press Facility

Large Extrusion Press

Column

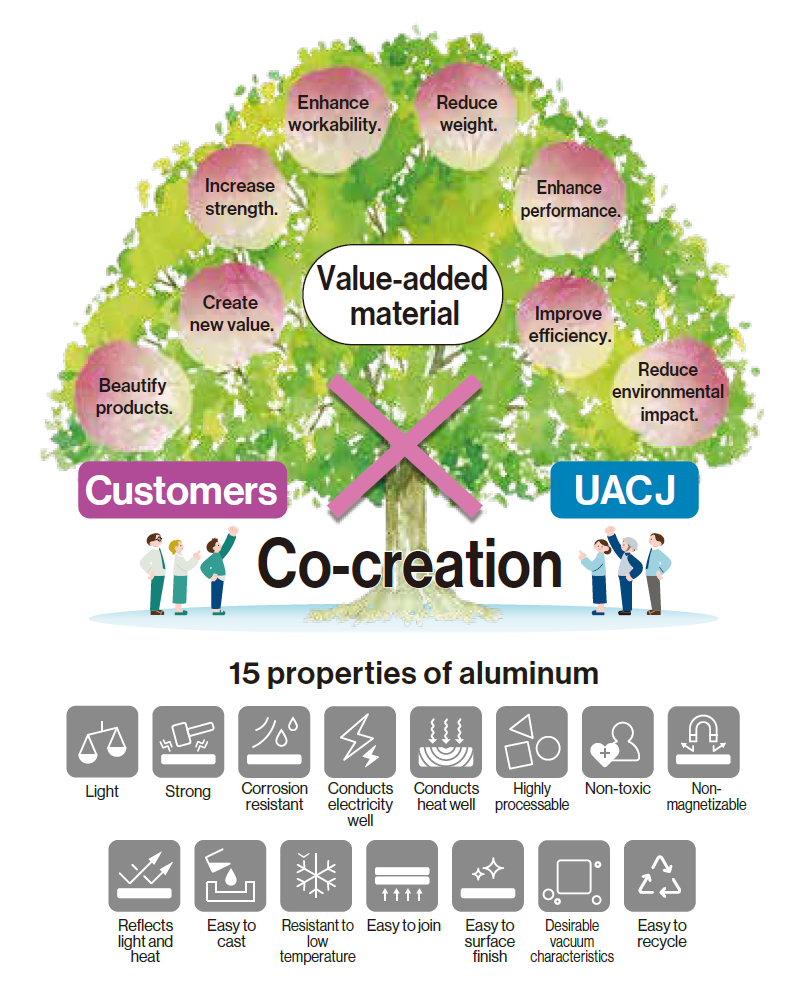

Toward a company that provides "material + α" added value

To maximize the properties of aluminum and further expand the appeal and potential of the material, UACJ is rolling out the aluminum material and product brand "ALmitas+," which expands the added-value concept of "material + α."

By combining UACJ's aluminum technology and manufacturing capabilities with customer needs, we provide products that offer the "+ α added value."

Thoroughly pursuing the possibilities of aluminum and realizing reduced environmental impact through R&D and product development capabilities

UACJ has its Research & Development Division and Mobility Technology Center (MTC) as facilities for R&D and product development.

We thoroughly pursue the possibilities of aluminum and tackle both technological innovation and reduced environmental impact.

Research & Development Division

This division handles all of UACJ's R&D, responds rapidly to customer needs, and develops innovative products and technologies that are one step ahead of the times. It advances fundamental materials research related to materials design and production processes, possesses state-of-the-art evaluation equipment including transmission electron microscopes for structural analysis and forming tests, and functions as an analysis center. In product development, it promotes the development of products for a wide range of applications and their application technologies.

Mobility Technology Center (MTC)

Bringing together the technology and know-how that we have cultivated over many years in aluminum for automotive parts, UACJ opened its Mobility Technology Center (MTC) in October 2020 as a global development base for its automotive parts business. The automobile industry is undergoing a once-in-a-century transformation, and the development of environmentally friendly forms of mobility such as electric vehicles has become indispensable. To meet these demands, UACJ maximizes the characteristics of aluminum and proposes highly functional and highly reliable products.

Column

"See, touch, and feel" aluminum technology: Come to U-AI Lab., a hub for promoting co-creation activities.

U-AI Lab. was established within the Research & Development Division in February 2019 as a venue for promoting co-creation activities at UACJ. At this facility, various exhibitions are conducted under the concept of letting people "see, touch, and feel" aluminum technology so that the technology can be widely understood.

03Aluminum that contributed to a sustainable society throughcontinuous recycling power

A familiar material that supports daily life and society

Aluminum plays an active role in every aspect of our lives.

Aluminum is used in diverse fields—from everyday items such as beverage cans and food packaging to transportation infrastructure including automobiles, railways, and aircraft, as well as electronic devices, industrial equipment, and architecture. Lightweight yet superior in strength, aluminum is a material that supports a comfortable society.

Aluminum: A sustainable material that is highly recyclable

Aluminum can be recycled any number of times and contributes to the realization of a sustainable society.

The energy required for recycling is kept to only about 3% of that needed for primary aluminum production, which leads to a drastic reduction in CO₂ emissions. Moreover, utilizing aluminum in food containers and packaging materials serves as an alternative to single-use plastics and also helps reduce marine plastic waste.

Aluminum achieves both environmental impact reduction and resource circulation, making it an indispensable material for a sustainable future.

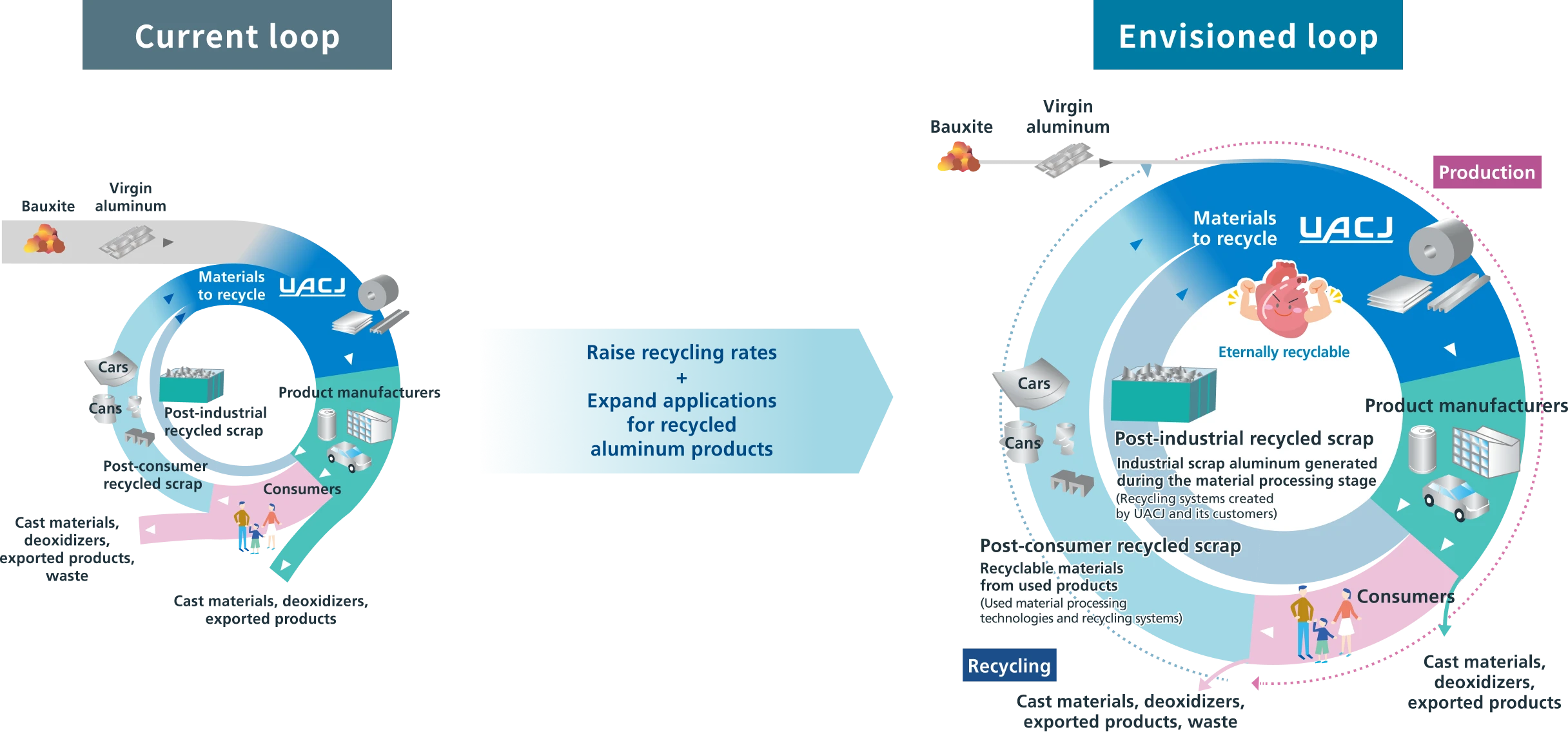

What UACJ thinks about "Building a society in which aluminum is recycled"

By connecting the "arteries" of the material (supply to manufacturing customers) with the "veins" (return of various scrap), UACJ undertakes the role of the "heart" that drives the circulation of aluminum through recycling.

We will continue to thoroughly pursue the possibilities of aluminum, take the lead in building a society where aluminum circulates, and keep working toward a future in which a beautiful and bountiful Earth that will last for years to come.

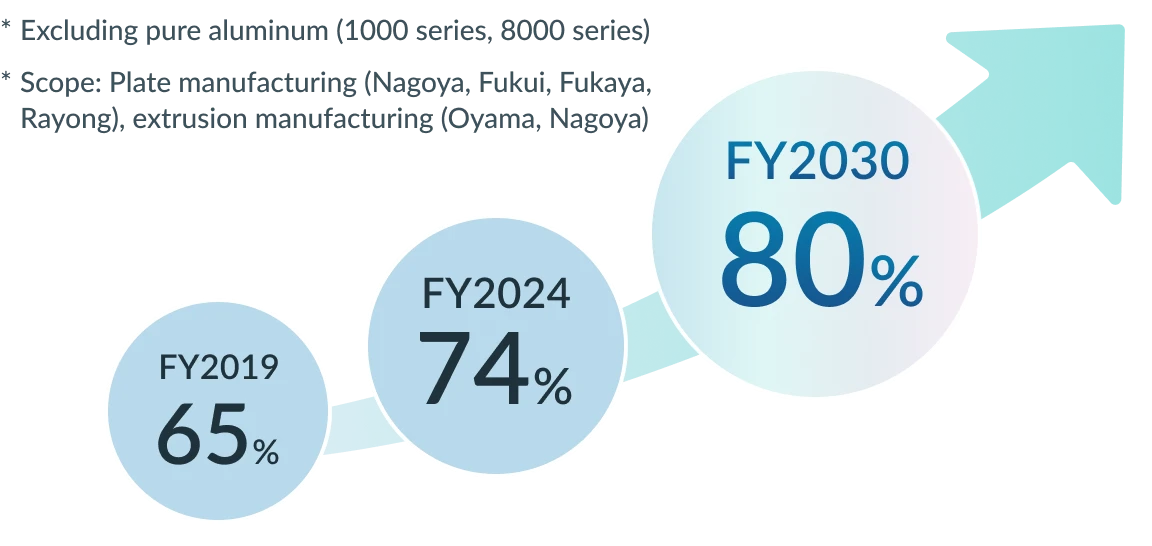

Trends in UACJ Recycling Rate Targets

Benefits obtained by achieving the target

- Reduction of CO₂ emissions

- Promotion of resource circulation(through increased use of recycled aluminum)

- Higher added value as an environmentally considerate product

Column

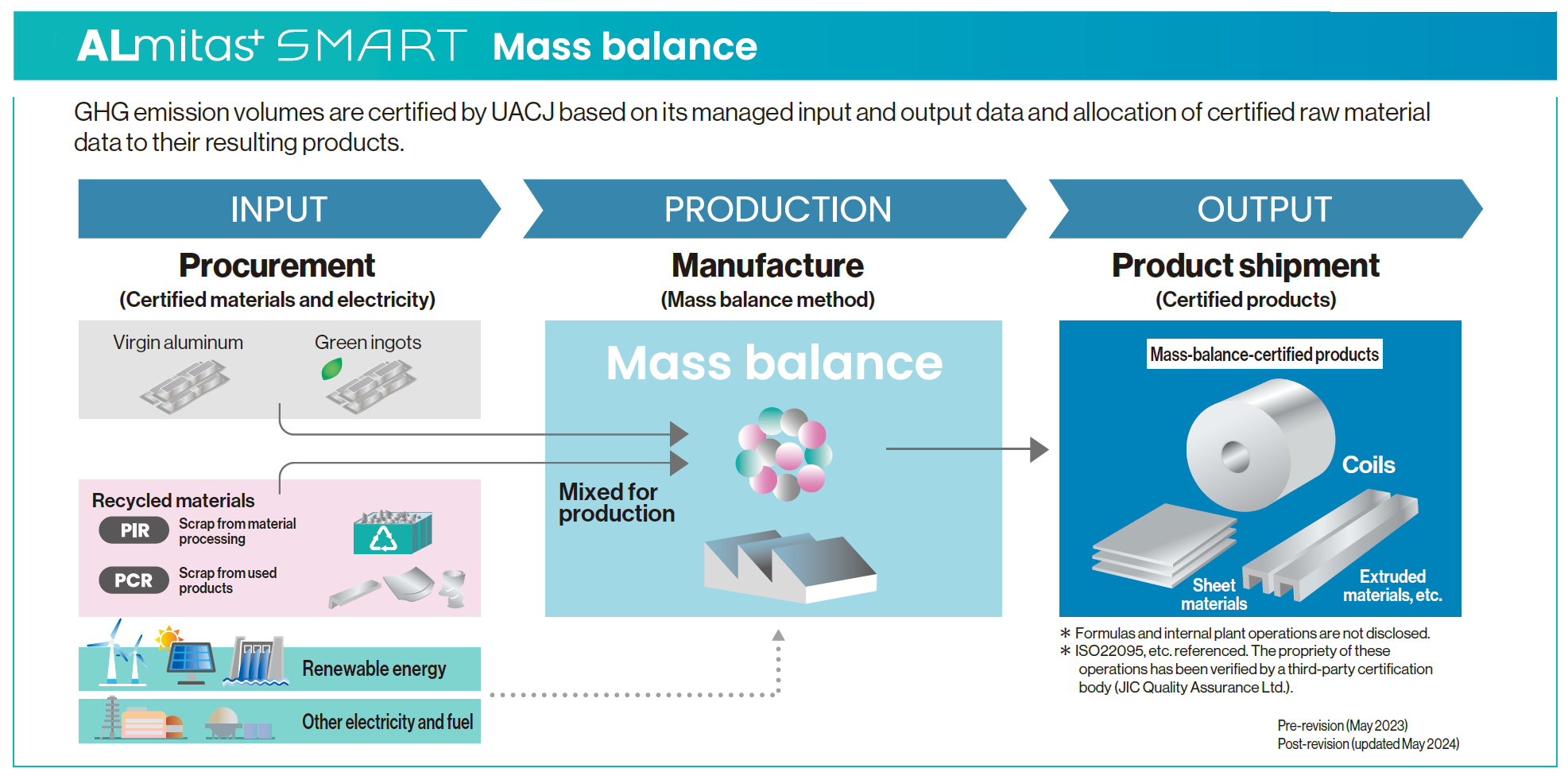

Promotion of the SMART brand (managed via the mass-balance method)

UACJ offers the environmentally considerate aluminum product line "ALmitas+SMART." SMART products achieve resource conservation and reduce environmental impact by lowering the usage ratio of primary aluminum. In addition, by applying the mass-balance method to consistently manage the flow from raw materials through to the final product, UACJ visualizes the actual effects of recycled material and renewable energy use and delivers highly reliable environmental value to customers. Adoption of this method not only strengthens competitiveness in the market as a sustainable option compared with conventional aluminum products but also contributes to corporate decarbonization and the achievement of product-related environmental targets.