Friction-Resistant Products for Compressors

Used in Components for Coolers, EcoCute and Other Air-Conditioning Devices

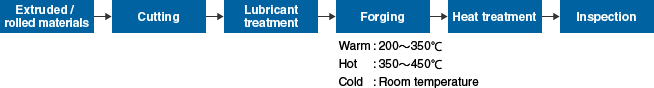

UACJ Corporation produces forgings at a wide range of temperatures, including cold forging, warm forging and hot forging. Its high-silicon wear-resistant alloy (TF Series) is used in compressor pistons and to improve wear on forged scroll components. Customers rate this material highly for its high strength and low degree of thermal expansion at high temperatures.

Features

- Warm forging and hot forging methods can also be used with hard materials having inferior processability (4032, 7075 alloys, and others) to produce desired shapes.

- As the resulting shape is near that of the finished product, yield is improved, saving material.

- As dimensional precision is good, the forged surface can be used as is, reducing machining cost.

Product Characteristics

Characteristics of wear-resistant materials

Material characteristics are for elemental (before forging) refined T6.

Tensile characteristics

| Alloy | Test temperature | Tensile strength N/mm2 |

Yield strength N/mm2 |

Elongation % |

|---|---|---|---|---|

| TF10B | 25°C | 360 | 280 | 13 |

| TF12B | 25°C | 435 | 380 | 8 |

| 150°C | 390 | 365 | 11.5 | |

| 4032 | 25°C | 380 | 315 | 9 |

| 6061 | 25°C | 310 | 275 | 12 |

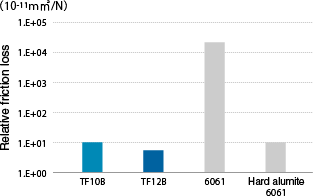

Wear resistance

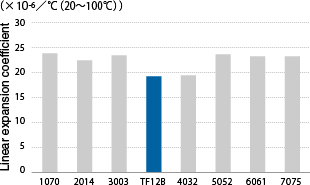

Linear expansion coefficient

Forging Process

Shaping Methods

Methods of shaping aluminum alloy forgings

Major Parts