Thick Plates

Aluminum Alloy Thick Plates (Lineup)For equipment and molds requiring high strength and processing precision

Aluminum alloys are used in various types of equipment and molds, thanks to their processability and light weight. The required strength and processing precision vary according to the application. UACJ offers a wide lineup of thick aluminum plates with differing characteristics to meet various needs.

- High-precision aluminum alloy plates

-

- High-precision aluminum alloy plate ALmitas+ FP52

- Standard aluminum alloy plate ALmitas+ FusPlate

- Plate for vacuum chambers Extra-thick Aluminum Alloy Plate

- ALmitas+ ALQUEEN300 aluminum alloy plate with the strength of steel

- Large, high-strength quenched plate

High-strength Aluminum Alloy Plate (Quenched Plate)

Features

Numerous alloy variations

We can manufacture various types of aluminum alloy plates using non-heat-treated and heat-treated alloys.

Extensive lineup

Our lineup includes various types of alloy plates, including high-precision, ultra-thick, and high-strength quenched material types.

World-class production capacity

With two manufacturing sites, the Fukui Works and Fukaya Works, we have established a system for supplying products within Japan and to overseas.

Comprehensive R&D capabilities, ranging from materials to products

We are engaged in total R&D, from basic aluminum technology to products and utilization technologies.

Lineup

High-precision aluminum alloy plate ALmitas+ FP52

A high-end product that features extremely high thickness tolerance and improved flatness tolerance. Strict gauge control and heat treatment technologies ensure vastly higher dimensional tolerance in comparison to our general-use plate products.

(Alloy, temper: 5052 - H112)

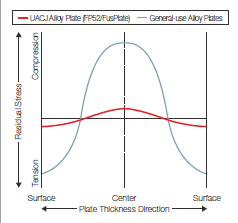

Product features

- Maximum plate thickness tolerance of approx. 1/10 of JIS standards achieved

- Near-complete elimination of residual stress vastly reduces the occurrence of warping in the cutting and machining processes.

- For superb surface quality the material can be used as is, with only mechanical surface finishing needed.

- Film affixed for surface protection

Standard aluminum alloy plate ALmitas+ FusPlate

ALmitas+ FusPlate is a general-use alloy plate with upgraded quality (JIS) and is the standard product among our lineup of aluminum alloy plates.

(Alloy, temper: 5052 - H112)

Product features

- Guaranteed level of thickness tolerance is one-third to one-fifth compared with JIS.

- Residual stress and flatness are improved over general-use alloy plates.

- Film affixed for surface protection

Plate for vacuum chambers Extra-thick Aluminum Alloy Plate

Employing the largest manufacturing facilities in Japan we manufacture extra-thick aluminum alloy plate that makes it possible to build larger manufacturing equipment for semiconductors and liquid crystal.

Product features

- Extra-thick plate is manufactured from Japan's largest slab (plate thickness 650 mm).

(Product size: Max. 640 mm thick, max 2,070 mm wide) - Excellent internal quality suitable for chamber material. Casting porosity (spherical cavities from gas generated in the molten metal) that occur in casting are eliminated by a special degassing process.

ALmitas+ ALQUEEN300 aluminum alloy plate with the strength of steel

ALmitas+ ALQUEEN300 is lighter and easier to machine than steel (S55C) and has equivalent strength. Corresponds to the 7075 alloy, the highest-strength aluminum alloy.

Product features

- High-strength aluminum alloy equivalent to S55C carbon steel for machine structures.

- Demonstrates excellent machinability. Takes only one-third to 1/50th the time to mill as steel.

- Low residual stress to minimize warp caused by machining.

- Lightweight and corrosion resistance for easy maintenance.

Characteristices comparison of ALmitas+ ALQUEEN300 and steel material

| Type | Mechanical properties (typical values)* | |||

|---|---|---|---|---|

| Tensile strength (N/mm2) |

Yield strength (N/mm2) |

Elongation (%) |

Hardness (HB) |

|

| ALmitas+ ALQUEEN300 | 510 | 450 | 12 | 140 |

| S55CN carbon steel for mechanical structures | 650 | 390 | 15 | 183 |

| SS400 rolled steel for ordinary structures | 400 | 215 | 23 | - |

* Typical values are indicated for ALmitas+ ALQUEEN300. Lower limit standard values are given for S55CN and SS400.

Large, high-strength quenched plate

High-strength Aluminum Alloy Plate (Quenched Plate)

We manufacture high-quality quenched plates using equipment that can manufacture plate material up to 3,000 mm in width.

Product features

- Residual stress is homogenized using Japan's largest stretcher (straightening capacity of 5,600 tons). (Post-cutting machining strain is minimized)

- 2000 series has superior heat resistance suitable for structural members that get heated.

- 6000 series is suitable for structural members and products that require thermal conductivity.

- The 7000 series has strength rivaling steel, and is applicable to products requiring superior cutting performance.

- Quenched materials demonstrate superior quality through production technologies developed from manufacturing aircraft material for Boeing and others; alloys can be selected for different purposes.

- Surface protection film can be affixed.

Properties Comparison

Characteristics comparison of alloy plate products

| Plate thickness precision | Appearance | Residual stress | |

|---|---|---|---|

| ALmitas+ FP52 | ★★★ | ★★★ | ★★★ |

| ALmitas+ FusPlate | ★★ | ★★ | ★★★ |

| General-use alloy plates | ★ | ★ | ★ |

Supporting a Wide Range of Dimensions

Higher plate thickness tolerance and flatness than ordinary types are achieved using sophisticated manufacturing technology. Supports a wide range of dimensional requirements such as plate width and thickness.