Printing

Lithographic Sheets (Presensitized Plate)Aluminum Sheet for High-Quality Lithographic Sheets

Aluminum is the ideal material for lithographic sheet because it is lightweight and recyclable. An electrochemical process gives aluminum sheets the surface roughness suitable for lithographic sheet. Therefore, aluminum sheets are commonly used as supports for lithographic sheet.

Features

- We produce sheets with superior surface quality—no dirt or surface defects.

- Heat treating keeps the sheet from changing shape by giving it excellent anti-thermosoftening characteristics.

- Excellent materials are used that are not distorted and that offer the high degree of planarity required of the lithogrqaphic sheet.

- Electrochemical processing is used to ensure consistent surface roughness.

Product Characteristics

Chemical composition of aluminum alloy 1050 for standard LPP (wt%)

| Alloy | Tempering | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | H18 | 0.25 or less | 0.40 or less | 0.05 or less | 0.05 or less | 0.05 or less | 0.05 or less | 0.03 or less | minimum 99.5 |

Mechanical property of aluminum material for typical presensitized plate

| Alloy | Tempering | Tensile strength (N/mm2) |

0.2% yield strength (N/mm2) |

Stretch (%) |

|---|---|---|---|---|

| 1050 | H18 | 160 | 150 | 3 |

Pattern diagram of roughened aluminum plate material

Brush graining

Nitric acid graining

Hydrochloric acid graining

after nitric acid graining

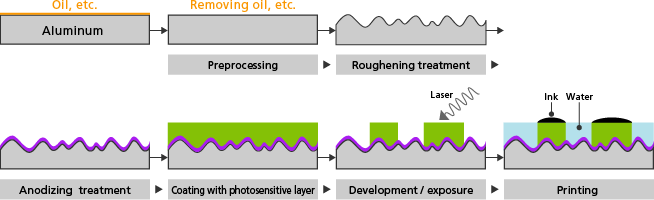

Production and printing process