Casting technology

- HOME

- Technology and R&D

- Equipment and Production Technology

- Casting technology

Providing uniform and highly reliable products with strict control and advanced technology

UACJ uses direct chill (DC) casting, which makes it possible to achieve high quality efficiently. By solidifying molten metal rapidly, high-quality slabs and ingots with few internal defects are produced and demonstrate excellent performance in sheet rolling and extrusion.

We also use low-pressure casting, which achieves uniformity and high dimensional precision, enabling us to provide high-strength castings in complex shapes.

DC Casting (slabs and ingots)

At an aluminum expanded material plant, the first process is melting/casting. This manufacturing process has the following important elements:

Quality Healthy component blend and ingots, and good cast structure

Productivity Dimensions, shape, and scale efficiency as required by hot processing

Economy Quality level of raw material, price, yield, and personnel

Safety Safety, anti-pollution measures, and energy savings

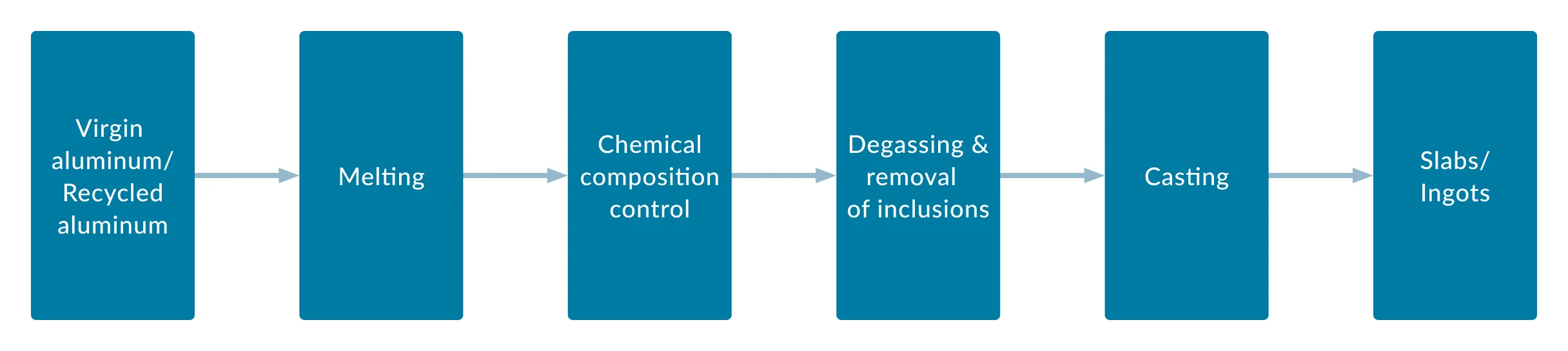

Flow from melting to casting

Aluminum metal and recycled materials are melted in a furnace, the alloy composition is controlled, impurities are removed, and molten metal with a uniform composition is produced, which is then cast into large aluminum slabs and ingots.

Melting

Raw material rapidly becomes molten in a melting furnace. In order to minimize the loss of molten metal, strict component regulations are applied. Our melting furnace is elaborately designed to maximize heat efficiency.

Molten Metal Processing

In-line continuous molten metal processing is performed, including removal of hydrogen gas and harmful trace elements from molten aluminum and separation of nonmetallic inclusions, to enhance ingot quality. This sophisticated molten metal processing is suitable for materials used in cans, automobiles, foil, aircraft parts, plates for semiconductor manufacturing equipment, memory discs, and other items.

Continuous casting

In 1944, we started using continuous casting technology, the first of its kind in Japan. Since then, we have long been a leader in casting technology, achieving Japan’s largest-class slab manufacturing, large ingot casting, and simultaneous casting of over 40 billets.

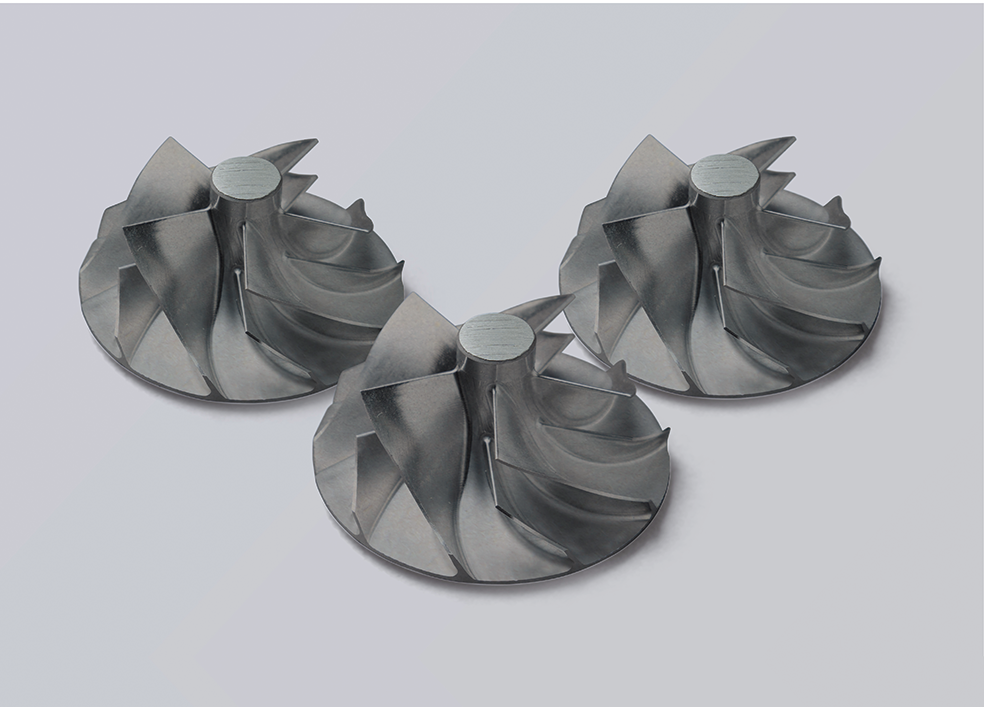

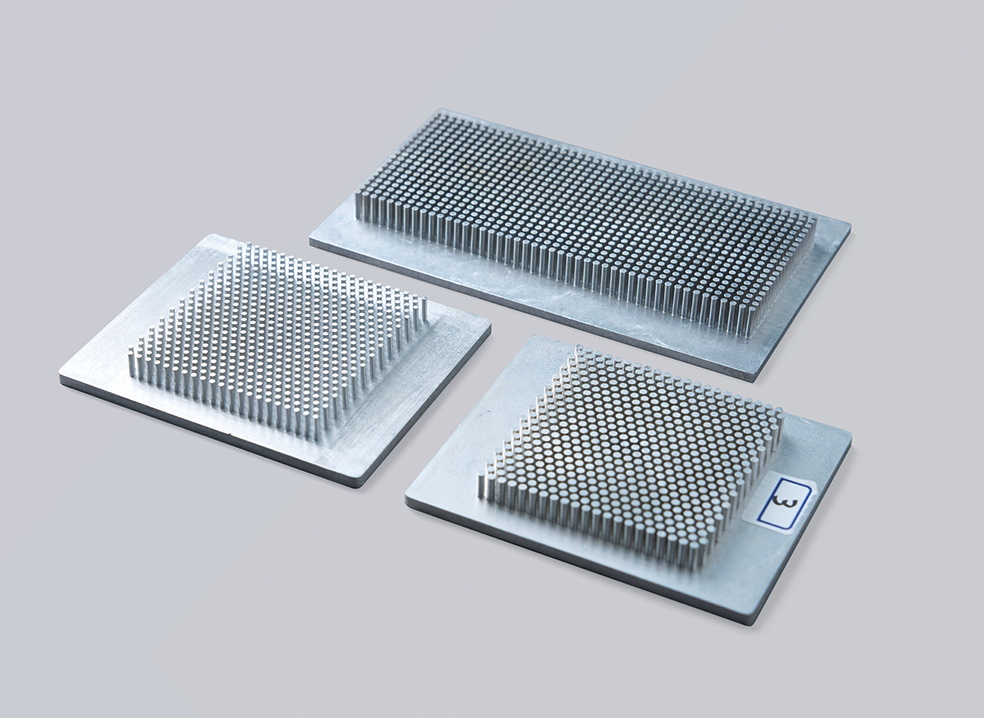

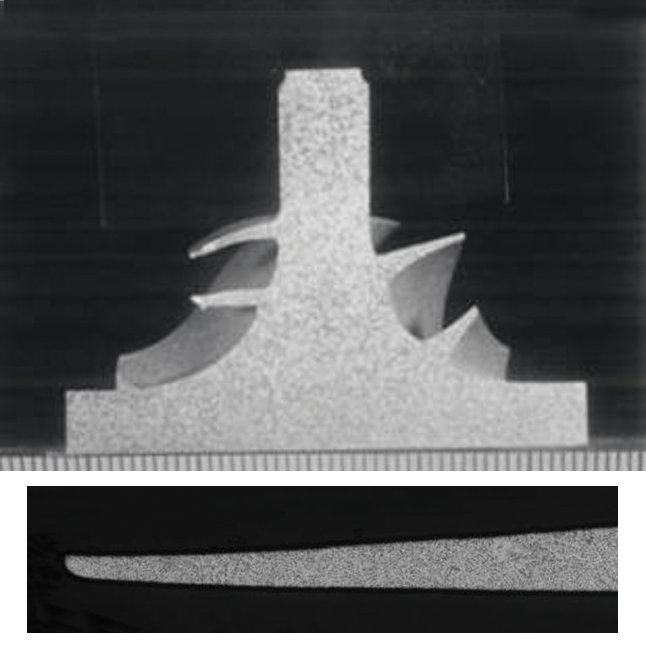

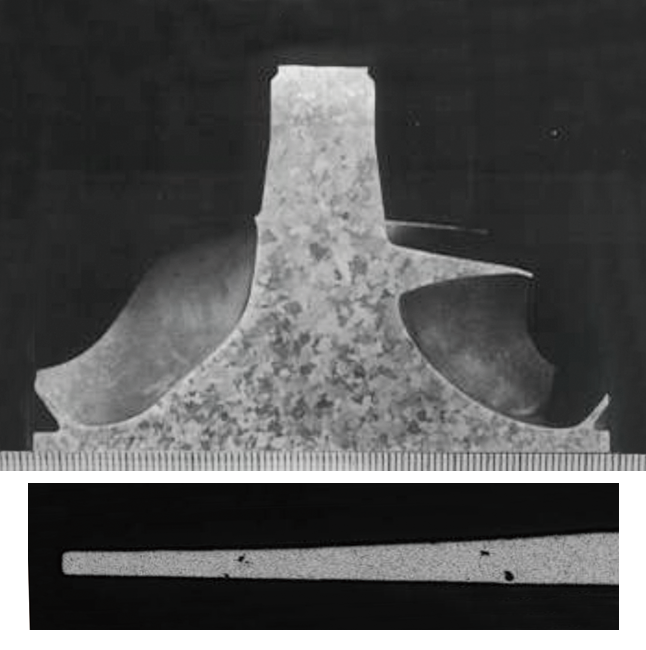

Low pressure die casting (compressor wheels and pin fin heat sinks)

UACJ manufactures high-precision and high-quality cast products using its original low pressure die casting technology. These castings, mainly compressor wheels for turbochargers and pin fins for water-cooled heat sinks, are supplied worldwide.

Low-pressure casting method

In the low-pressure casting method, gas at a low pressure is applied to molten aluminum to push it into a specific product mold. As this technique suppresses interior defects caused by the entrainment of aluminum oxide or other reasons during casting, it ensures stable production of high-quality aluminum castings with superior strength, durability and dimensional precision.

Examples of aluminum precision castings