Extrusion technology

- HOME

- Technology and R&D

- Equipment and Production Technology

- Extrusion technology

Extrusion technology to meet varied quality requirements for aviation, space, and many other fields

Extruded materials are used for diverse applications ranging from automotive heat exchangers (radiators and condensers) to outdoor products, transport vehicles, and aircraft. Powered by a number of 5,600-metric-ton large extrusion presses and indirect presses suitable for high-strength extrusion, UACJ makes aircraft materials, motorcycle front forks, and other products requiring extremely high quality.

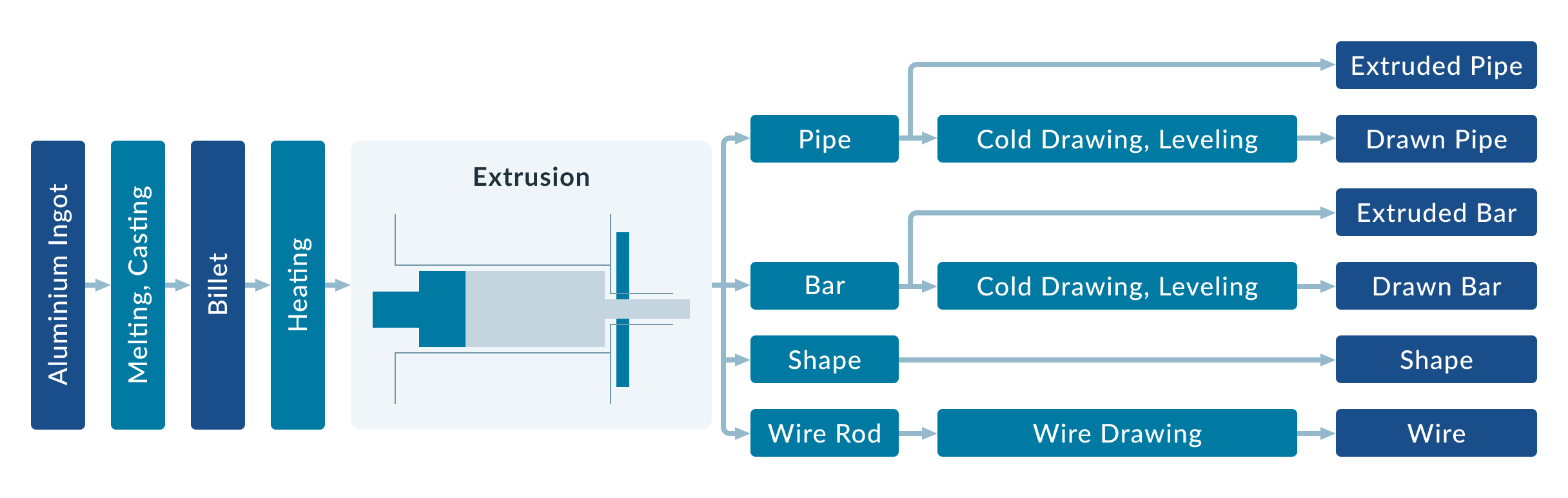

Manufacturing Process for Aluminum Extruded Material

Extrusion is used to manufacture products that have different cross sections. Aluminum ingots, called billets, are extruded at high pressure and temperatures of 350°C to 550°C through dies of different shapes to manufacture products.

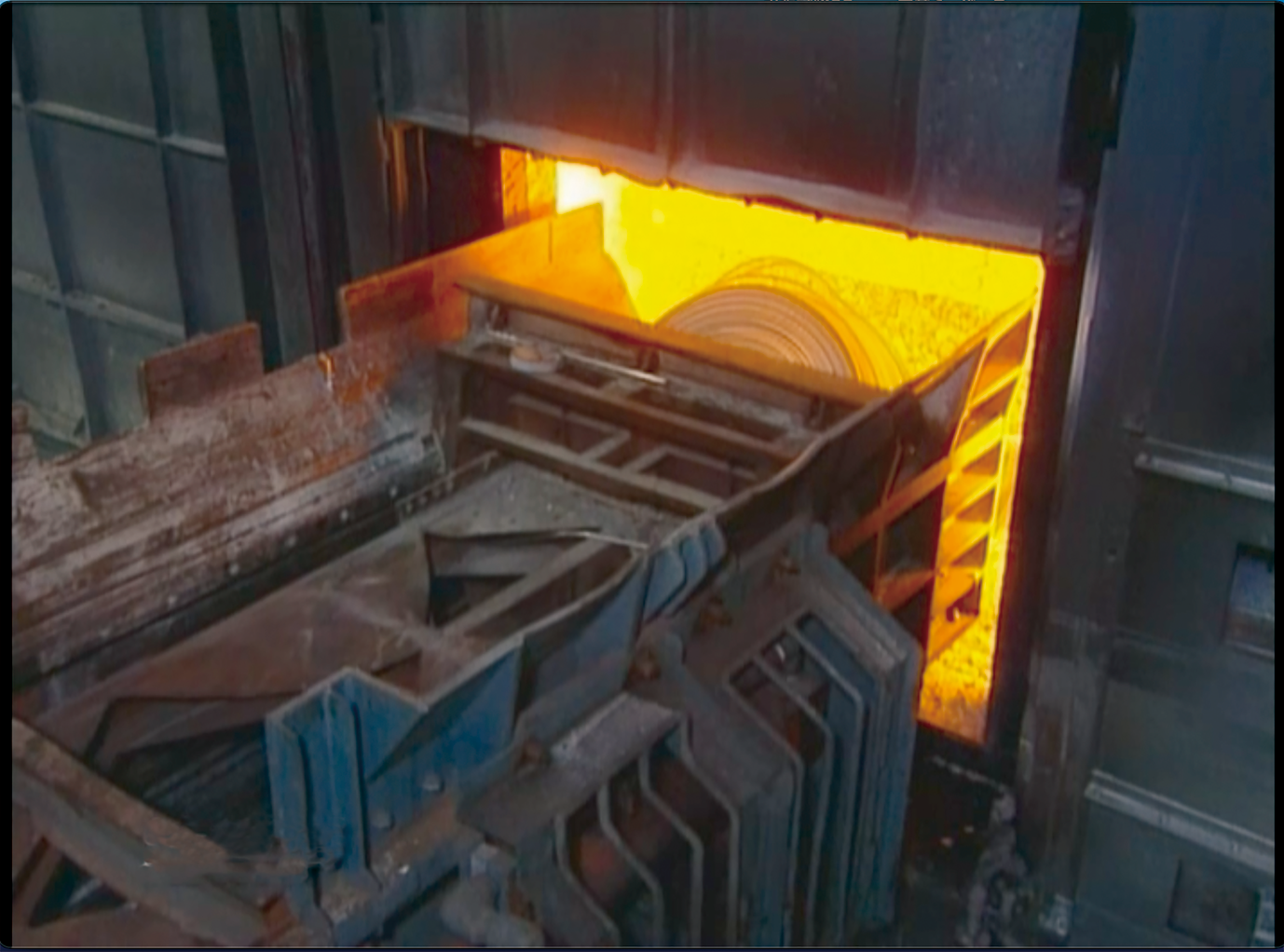

Melting & Casting Process

Virgin ingots and recycled raw materials are melted and adjusted to a specific composition to make aluminum alloy billets. These billets are prepared in several diameters to match the size of the material to be extruded.

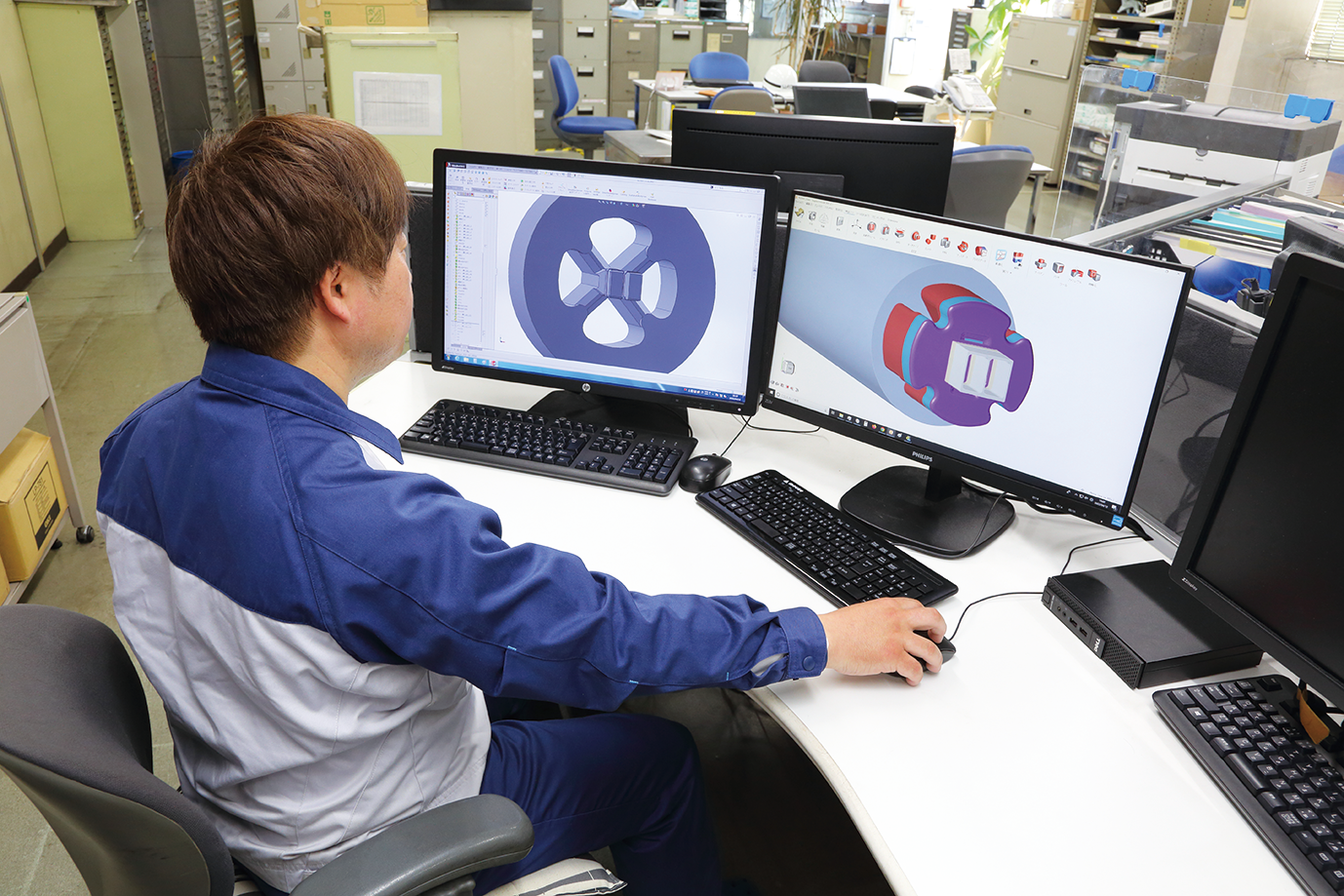

Die Design & Extrusion Process

We employ a state-of-the-art CAD system to design extrusion dies, and are working to design dies that best suit the profile of the product. These dies are then hot processed into their respective profiles.

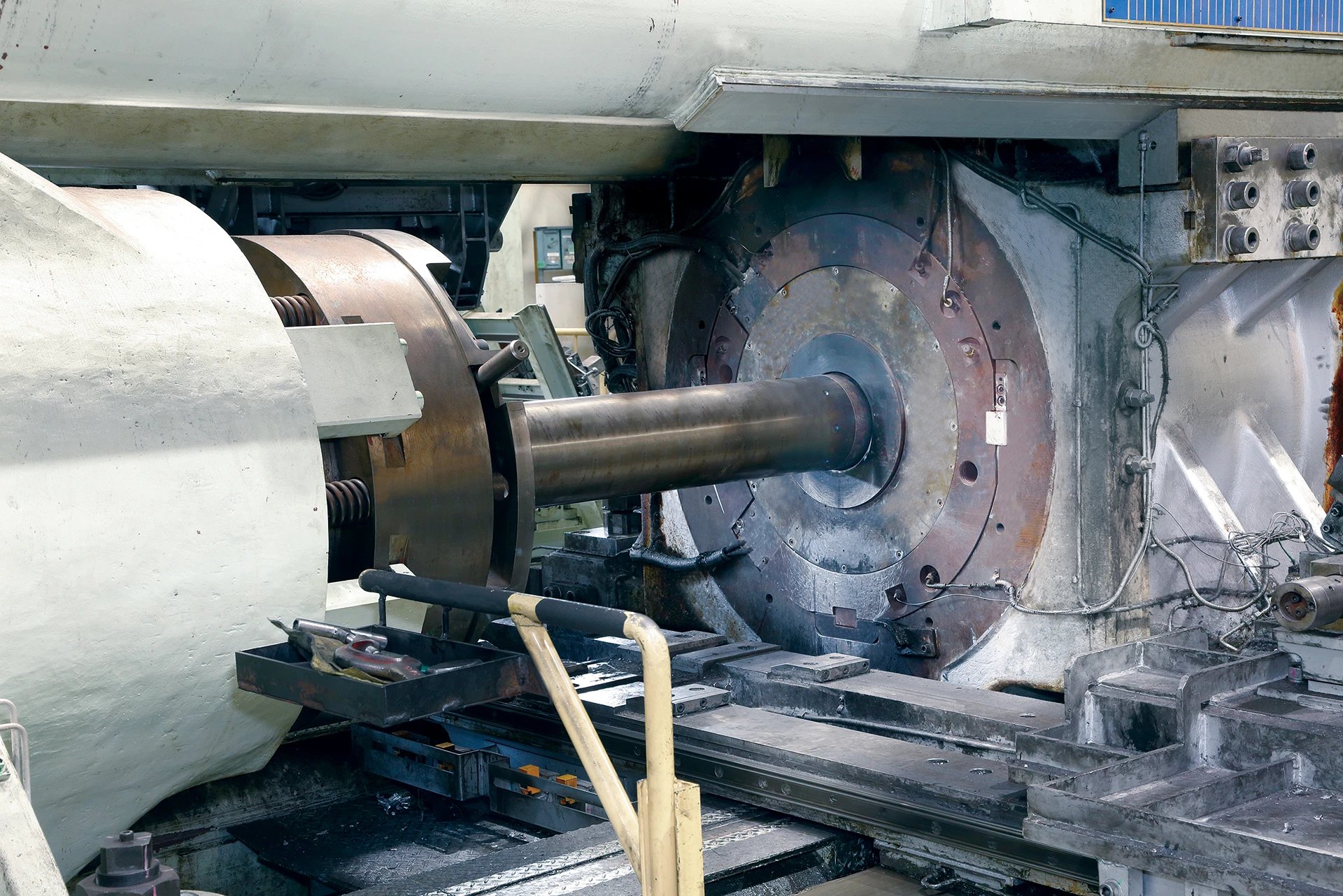

Extrusion Press Exclusively

for Alloy Pipes

Extrusion Types

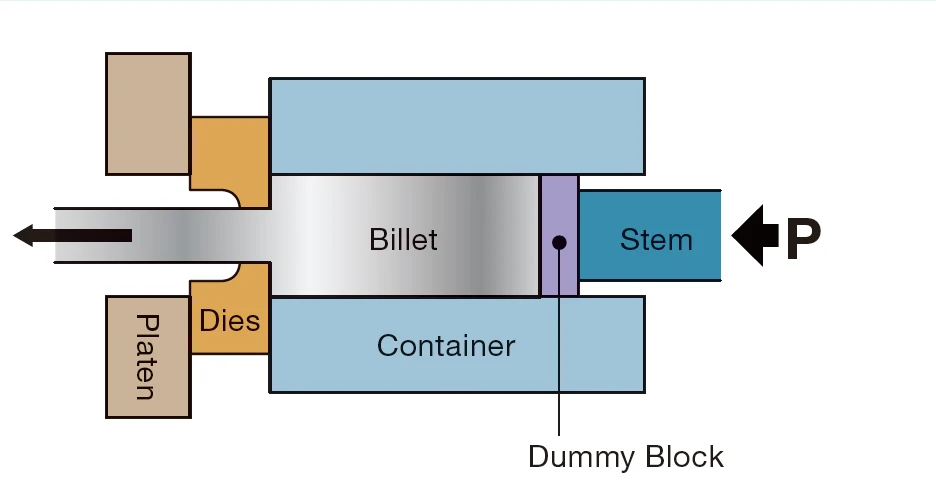

Direct Extrusion

- A process in which the die and container are fixed, and the billet is pressed against the die.

- Generally, profiles, rods, and soft alloy tubes are produced by this direct extrusion method.

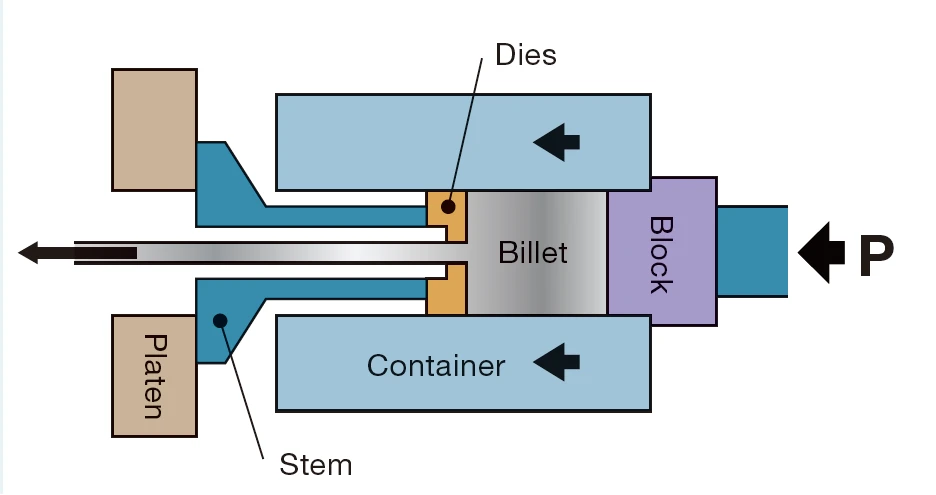

Indirect Extrusion

- A process in which the container is fixed and the die is moved to the billet.

- This process causes little friction between the billet and the container and thus is ideal for high-strength materials with uniform metal structure.

- Uniform deformation and temperature distribution make it possible to achieve high dimensional accuracy.

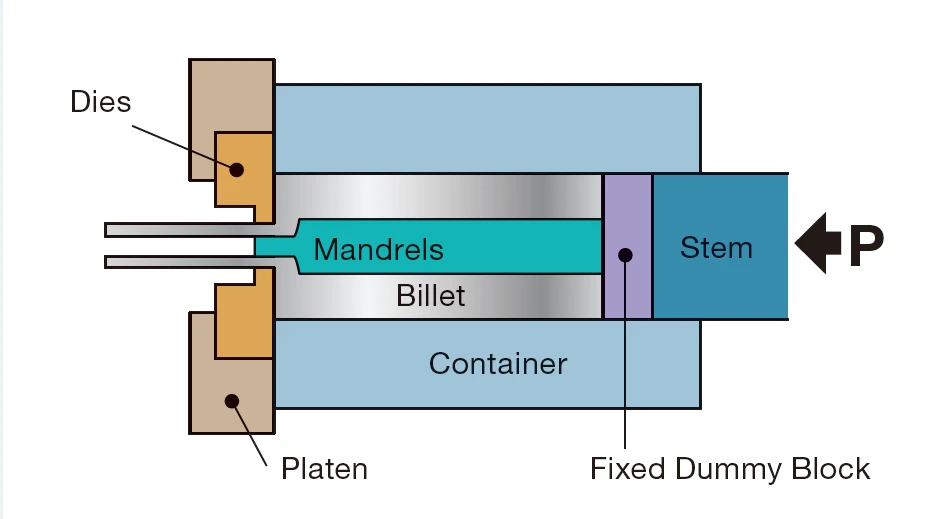

Hollow Extrusion

Mandrels

- The mandrel is placed in the center of the die and the billet is forced out to form a hollow shape (tube).

- The result is uniform wall thickness and a smooth inner surface.

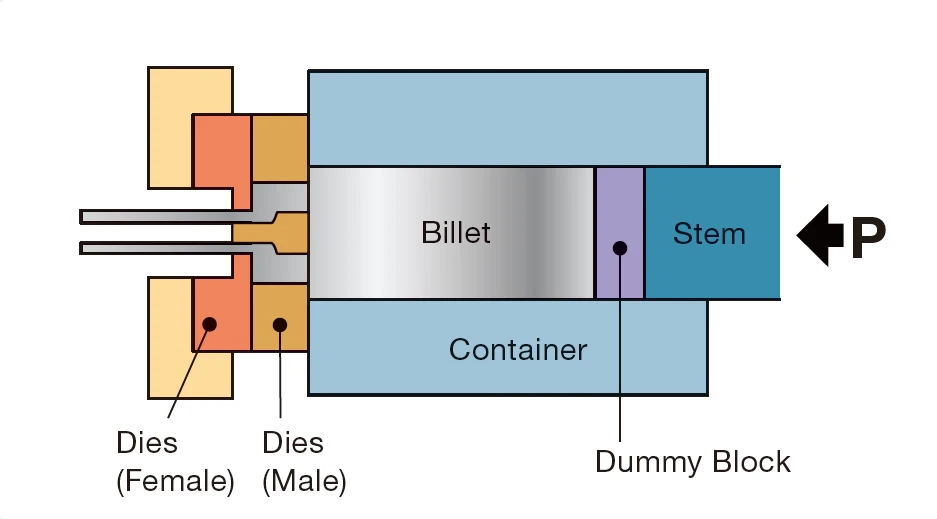

Porthole

- Hollow shapes are manufactured.

- Complex cross sections can be made efficiently.

Finishing

After extrusion, tubes and bars are drawn at room temperature to improve dimensional accuracy and strength and to straighten them. Some materials are heat-treated to adjust their strength according to customer requirements.

Drawing Method

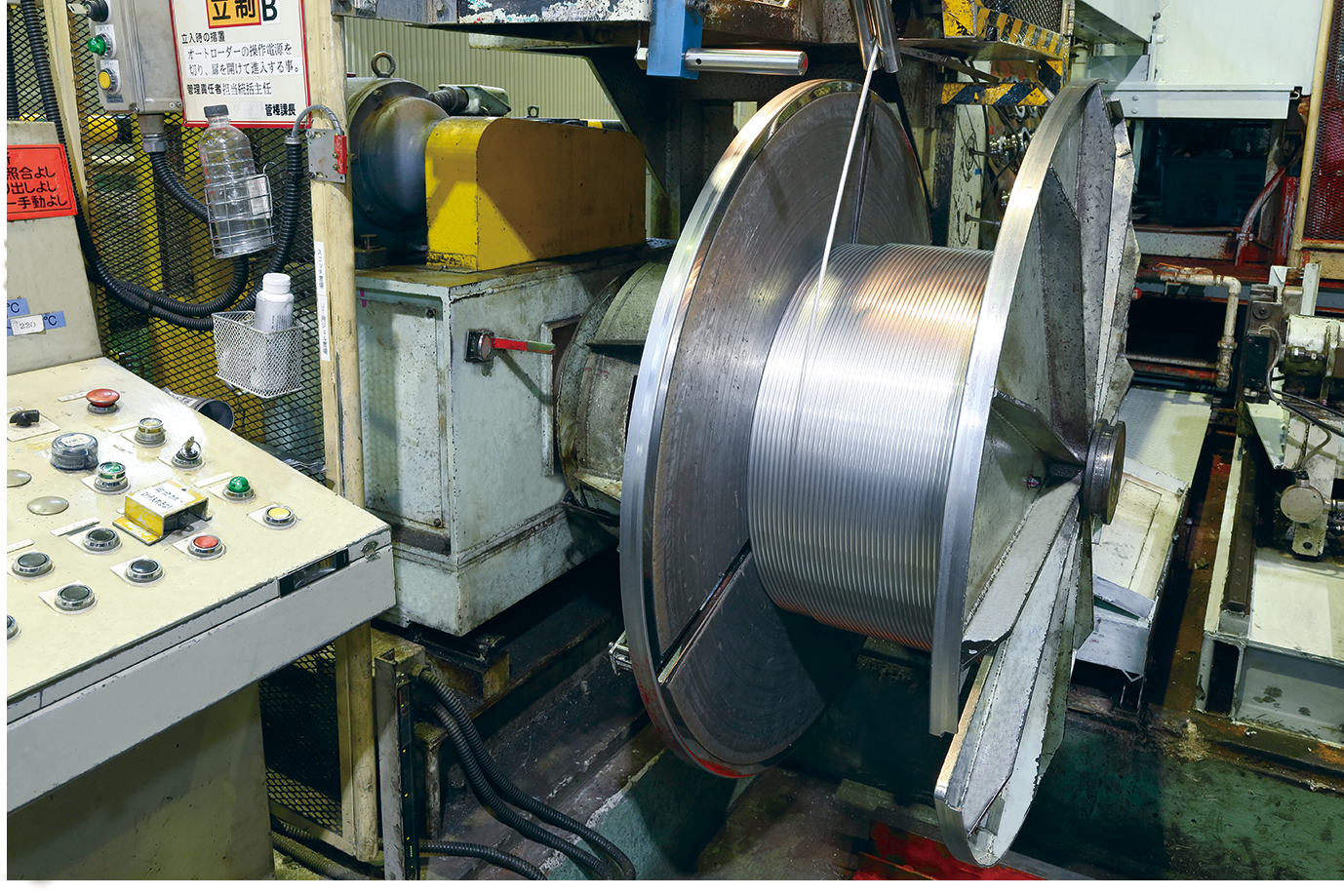

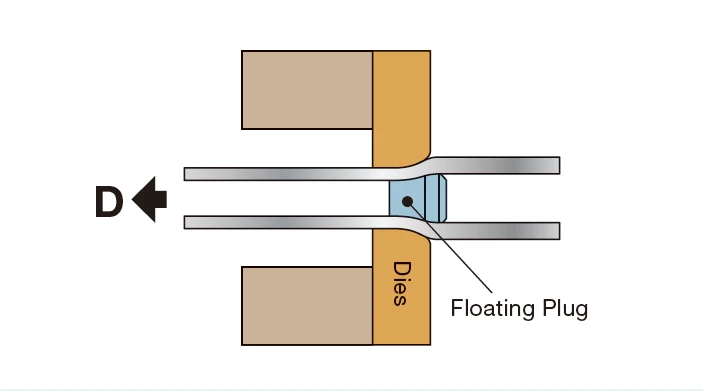

Bull Block Drawing

- The material is drawn as it passes between the die and the floating plug to improve the dimensional accuracy, surface quality, and mechanical strength.

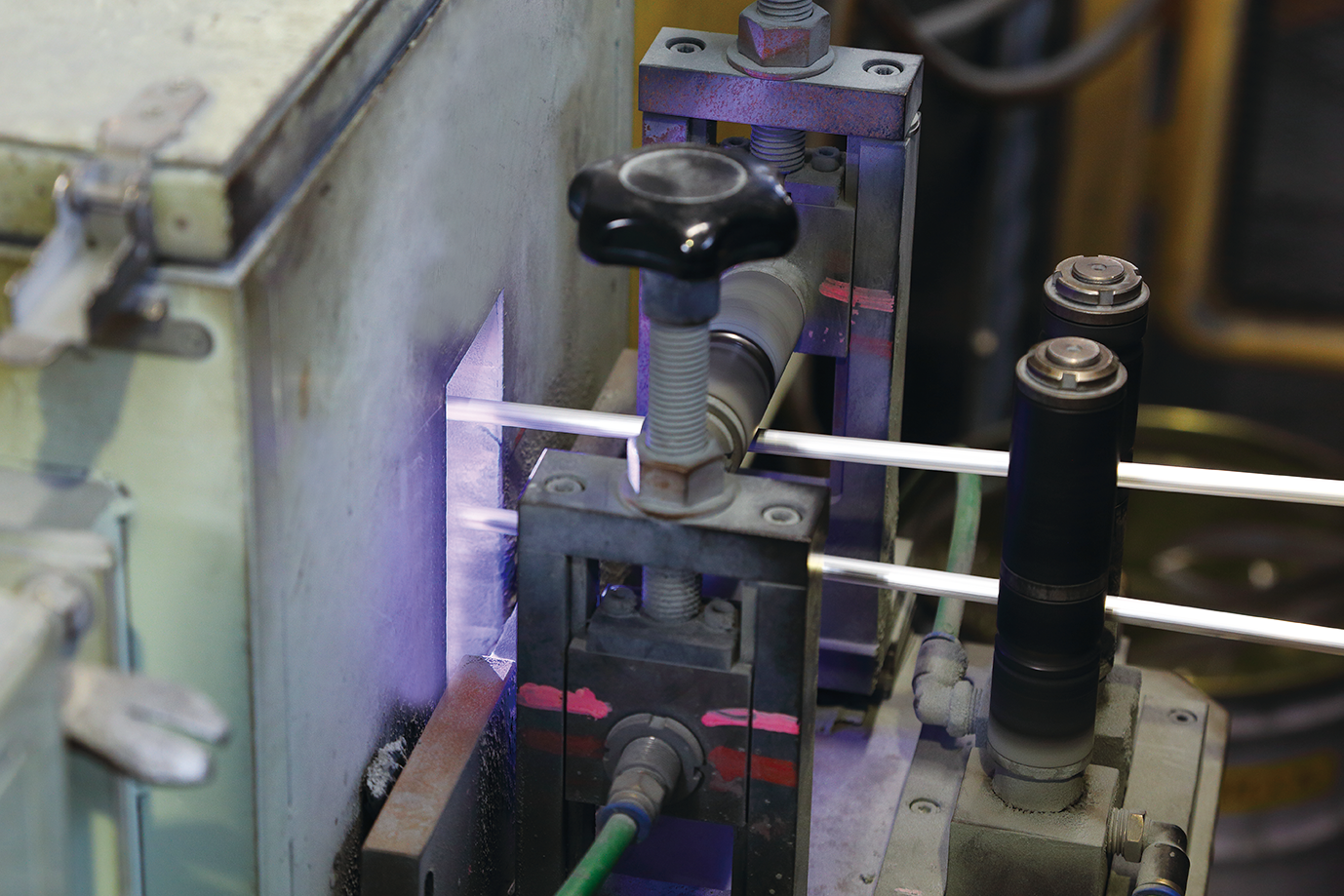

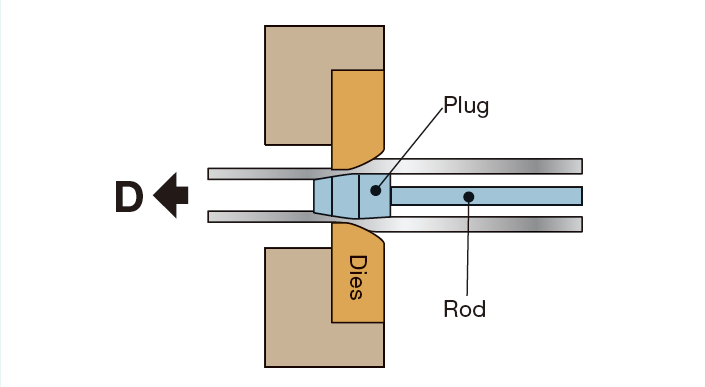

Bench Drawing

- A long pipe is drawn through the die to produce a pipe with precise dimensions and a high-quality surface finish.