Mobility Technology Center (MTC)

- HOME

- Technology and R&D

- R&D

- Mobility Technology Center (MTC)

By harnessing the combined strength of the UACJ Group, we deliver rapid, proposal-driven development for automotive parts.

The Mobility Technology Center (MTC) harnesses the combined strength of the UACJ Group to globally deploy rapid, proposal-driven development for automotive parts. The MTC serves as our central hub for technology development that addresses the shift from automobiles to mobility.

In October 2020, we established the MTC as a global hub for automotive parts development. The name of the center embodies our aspiration that it will serve as the central force in technology development capable of addressing the anticipated shift from automobiles to mobility (means of transportation) in the near future.

- One-stop service that contributes to the efficiency of our customers' manufacturing processes

- Simulation technology enhancement to shorten development lead time

- Improving product development and development processes through prototype evaluation

- Identifying technology trends through benchmarking studies

- Technology and Research Journal

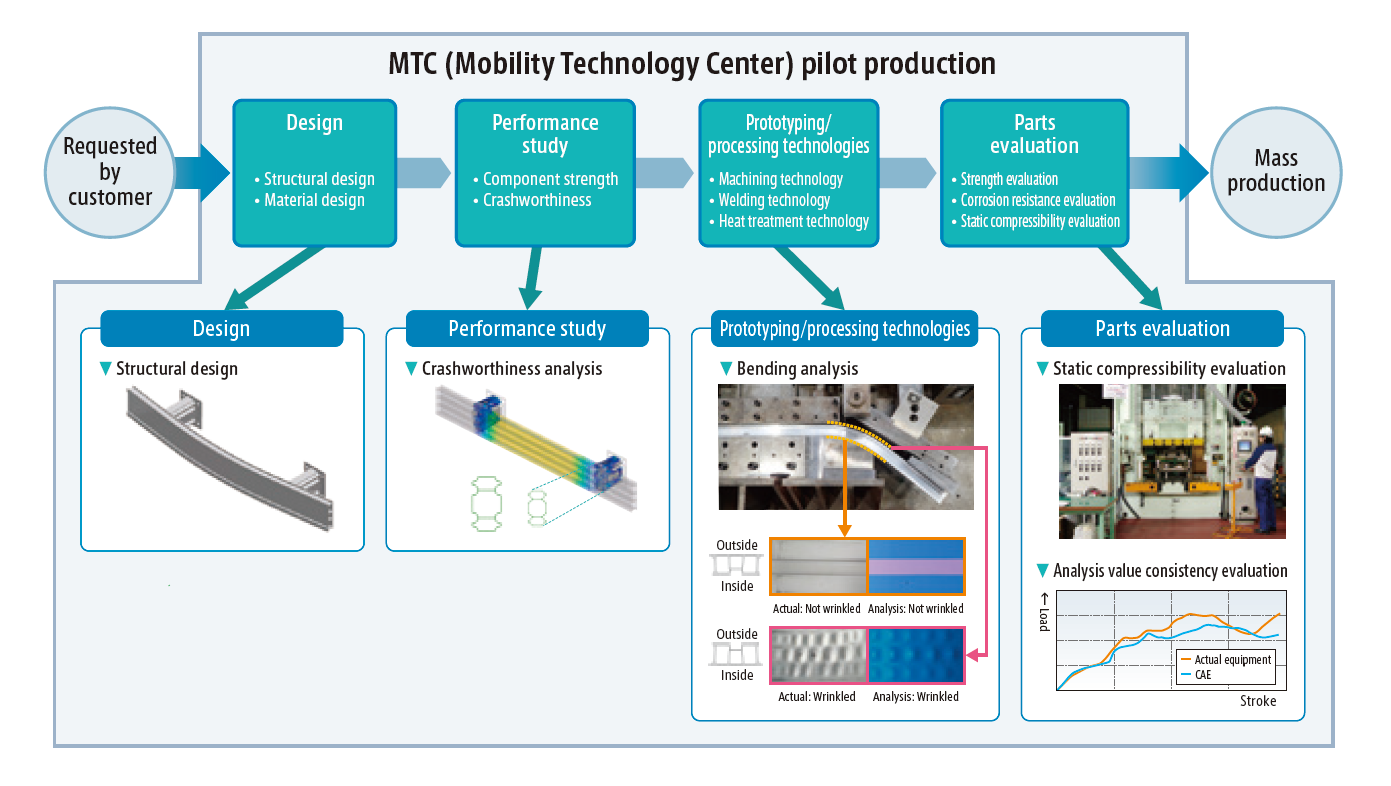

One-stop service that contributes to the efficiency of our customers' manufacturing processes

- We offer one-stop service to fulfill customer requests, from planning and product design (including alloy composition and structural design) to manufacturing, sales, and quality assurance.

- Leveraging our expertise as an aluminum manufacturer, we plan, design, and develop optimal products.

- Through close collaboration with automakers and component manufacturers, we contribute to our customers’ seamless manufacturing.

Simulation technology enhancement to shorten development lead time

Using automotive part design data, we evaluate part performance by simulating strength/durability, impact, heat, and other loads. We explore a range of test conditions and are working to improve prediction accuracy through highly accurate representations of the material properties of aluminum and joints. The resulting accurate simulation results are fed back to the design process to improve design completion prior to prototyping, and reduce overall development lead time.

Improving product development and development processes through prototype evaluation

Products whose performance has been evaluated by simulation are prototyped, taking into account the production process, and are then transferred to prototype evaluation. Through repeated design, simulation evaluation, and prototype evaluation, we develop high-performance, high-quality products. Furthermore, the know-how gained through development is utilized to propose more competitive products.

Identifying technology trends through benchmarking studies

Utilizing evaluation technology developed by the Research & Development Division, we survey the automotive parts market regularly to identify technological trends. Through comprehensive analysis of such parameters as material properties, processing technologies for forming and joining, and rigidity and impact absorption performance, and by thoroughly considering the required qualities as reflected in product structure and shape, we can anticipate future customer requirements and enhance our design proposal capabilities.

Technology and Research Journal

Technology and Research Journals section introduces the UACJ's research achievements.

You can also view back issues of UACJ publications, as well as technical and research journals published by the former Furukawa-Sky Aluminum Corp. and the former Sumitomo Light Metal Industries, Ltd.