Processing technology

- HOME

- Technology and R&D

- Equipment and Production Technology

- Processing technology

Processing technology leveraging our expertise in metals

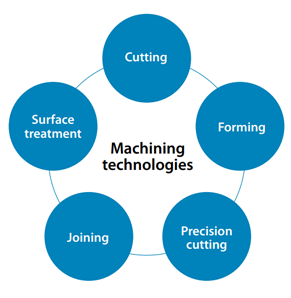

Aluminum products are used for a wide variety of applications, from transport vehicles such as automobiles and aircraft to the construction industry. They also come in many different shapes and sizes. These products are created by diverse processing techniques. We perform a wide range of processing such as cutting, milling, forming (e.g., bending and drawing), joining of dissimilar materials or various shapes of members, and surface treatment including coating, coloring, and anodizing. We provide one-stop solutions from the design stage to meet customer needs.

Machining

The high-rigidity double-column machining center handles large pieces up to 4 m. With the spindle attachments, it is capable of five-sided machining. This tool is suitable for machining of products used in the aerospace industry as well as in LCD/semiconductor manufacturing equipment.

Main machine tools

- Vertical machining center and vertical 5-axis machining center

- Horizontal machining center and horizontal 5-axis machining center

- Double-column machining center

- Horizontal NC lathe and vertical NC lathe

- Drilling, long work machining, etc.

3D bending

A CNC 3D bender enables 3D bending into a complex and continuous shape, which is difficult to achieve with conventional benders, while also helping to shorten the preparation period for mass production and drastically reduce the die cost.

Cutting

We possess various cutting machines and perform highly accurate, stable cutting, considering the material properties. These machines include not only precision cutting machines, angle cutting machines, and automatic pipe cutting machines but also 3D cutting machines.

Press forming

We offer a one-stop service from designing to die fabrication, forming, and finishing. Making the most of the properties of aluminum, we perform high-precision, high-efficiency processing and provide automotive parts, electronic parts, and many more with consistent quality.

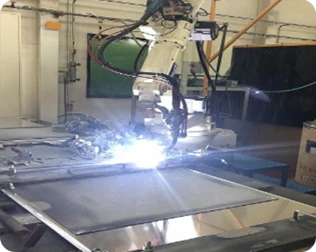

Joining and Welding

Leveraging our extensive expertise in aluminum, we propose joining solutions that suit the purposes of individual products ranging from small parts to large structures, and contribute to reducing the weight of electronic parts and transport vehicles.

Joining techniques and features

| Type | TIG welding | MIG welding | FSW | Resistance spot welding | Laser welding |

|---|---|---|---|---|---|

| Features |

|

|

|

|

|

Fitting technology

By fitting extruded materials together, no bolts are needed for the joint, which reduces weight and processing man-hours. These products are widely utilized for truck platform gates and flood barriers.

Anodizing

Anodizing is a process of forming an oxide film on the surface of aluminum. It imparts high corrosion resistance and drastically extends product life. Anodized aluminum is used for various purposes including truck platform gates and building materials.