Waste Reduction

Our Approach

The recoverable reserves of aluminum, our Group’s core material, are abundant compared to other metals, giving it what is called a “long mining life.” Nevertheless, we believe it is important to promote reuse and recycling in order to pass on resources to future generations.

In recent years, marine plastic litter has become a major social issue, highlighting the need to create a plastic-free and recycling-oriented economy. With this in mind, we are actively expanding our recycling efforts for aluminum cans and automotive parts to include horizontal recycling *1, where a used product is recycled to use as a resource to make the same product again. We are also continuing efforts to fulfill our environmental activity target to help realize a recycling-oriented society by working to lower our basic unit of industrial waste volume and by promoting the 5Rs, which add Refuse and Repair to the 3Rs of Reduce, Reuse, and Recycle.

- “Horizontal recycling” refers to the use of scrap from used products to produce raw materials to make the same kind of products again.

Key Initiatives

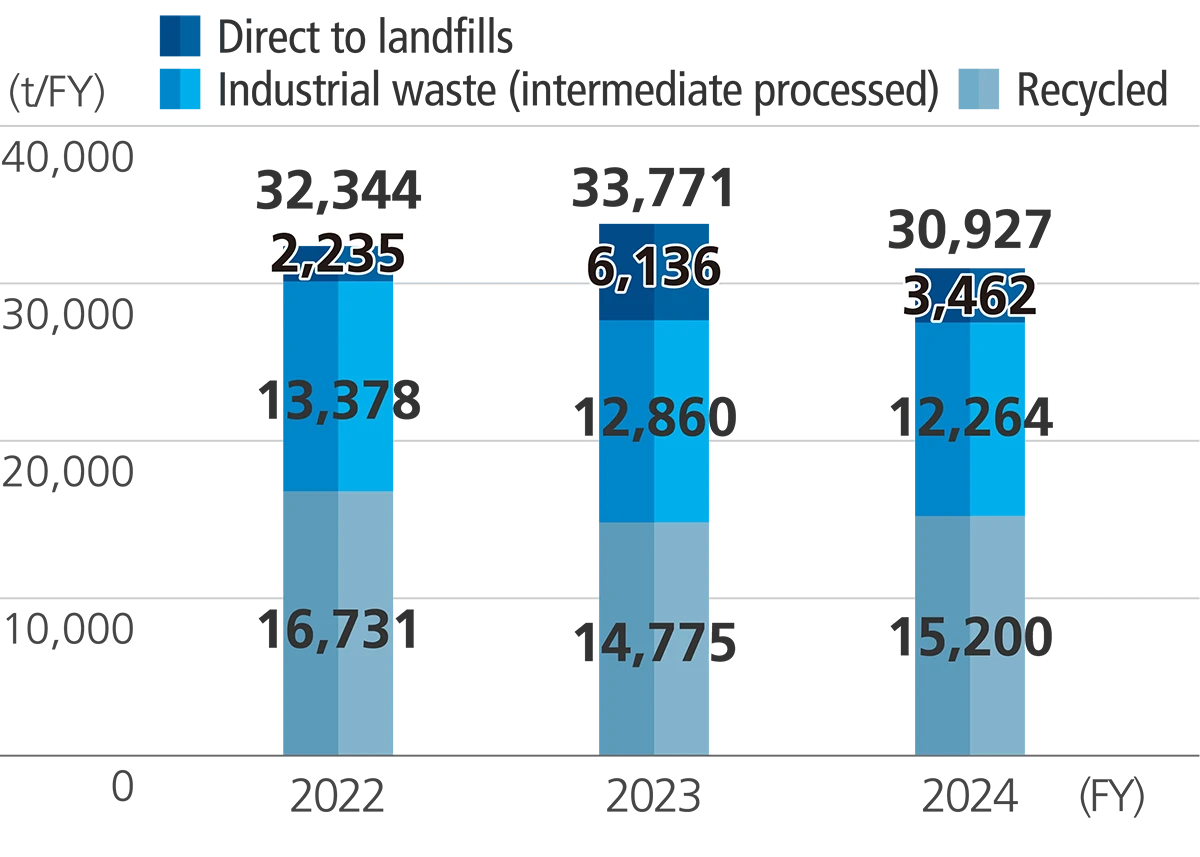

Trends in industrial waste volume

The total industrial waste generated across all business sites in fiscal 2024 was 30,927 tons, representing a decrease of 8.2% from fiscal 2023. This is the result of reduction efforts, including proper sorting and resource recycling.

We will continue doing our part to create a recycling-oriented society by reducing and recycling industrial waste and promoting the conversion to more efficient resources.

The direct landfill ratio at our domestic business sites was 0.20%, as we continued to achieve our target of virtually zero emissions (direct landfill ratio of less than 1%).

Amounts of Industrial Waste Generated by the UACJ Group (Japan + overseas)

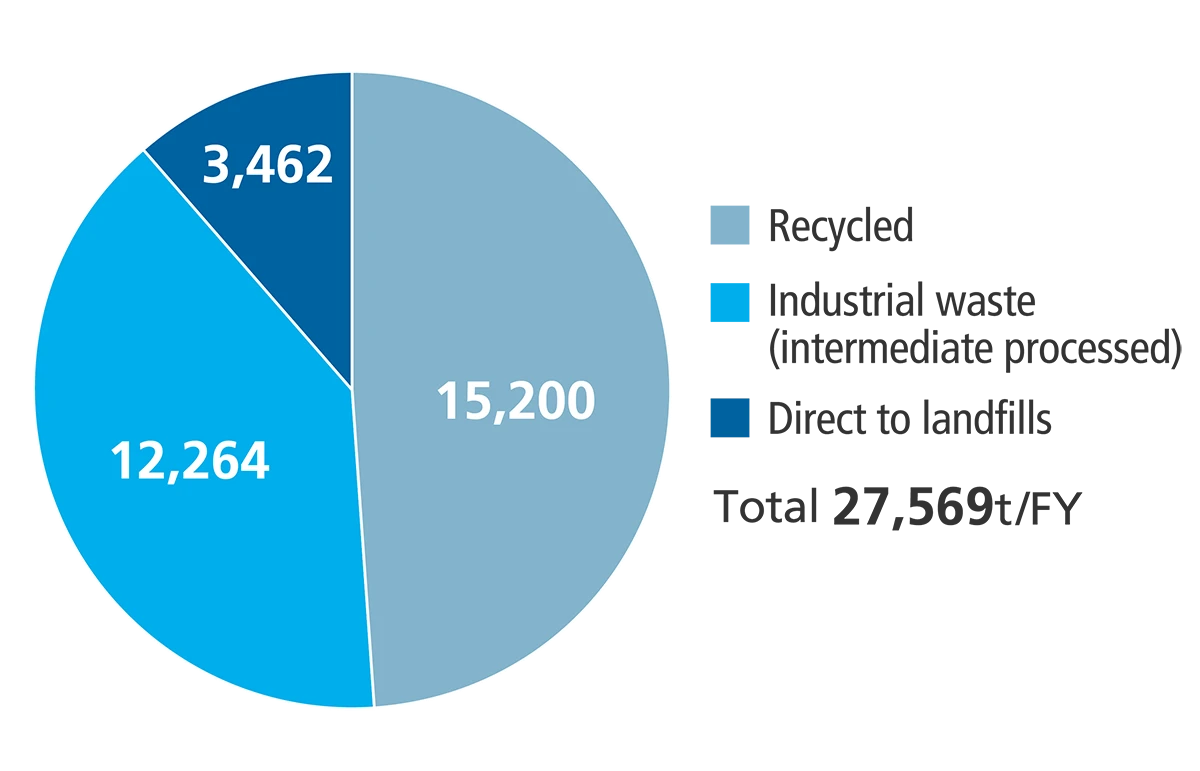

Breakdown of UACJ Group Waste by Handling Approach (FY 2024・Japan + overseas)

- Note 1 Measurement scope:

(Japan) UACJ (Nagoya, Fukui, Fukaya), UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum), UACJ Extrusion Nagoya Corporation (Nagoya, Anjo), UACJ Extrusion Oyama Corporation, UACJ Extrusion Shiga Corporation, UACJ Extrusion Gunma Corporation, UACJ Foil Corporation (Shiga, Nogi, Isesaki), UACJ Foundry & Forging Corporation

(Overseas) UACJ (Thailand) Co., Ltd., UACJ Extrusion Czech s.r.o., UACJ Extrusion (Thailand) Co., Ltd. (Prachinburi Works), UACJ Foundry & Forging (Vietnam) Co., Ltd., UACJ Foil Malaysia Sdn. Bhd., UACJ Automotive Whitehall Industries, Inc. - Note 2 Companies and sites as of September 30, 2024.

Waste Amounts by Type and Main Post-Recycling Application (FY 2024, Japan)

| Waste Type | Tons Generated | Percent Recycled | Main Post-Recycling Application |

|---|---|---|---|

| Sludge | 7,445 | 79 | Raw material for cement |

| Waste oil | 2,347 | 84 | Fuel |

| Wood waste | 1,576 | 93 | Fuel, fertilizer |

| Waste plastic | 1,204 | 51 | Fuel |

| Slag | 1,006 | 100 | Roadbed material |

Industrial Waste Reduction Examples (Fiscal 2024 Activities)

| Business Location | Theme | Reduction (t/yr.) |

|---|---|---|

| Nagoya Works | Reduction of sludge through improvement activities | 78 |

| Multiple operating sites | Reduction of waste plastics through reuse and conversion to value | 13 |

Industrial Waste Subcommittee

At UACJ, the Industrial Waste Subcommittee, which consists mainly of representatives from our Japanese business locations generating significant amounts of industrial waste, meets regularly to promote the reduction and proper processing of industrial waste. We achieve this by establishing a common understanding of separation and processing information, and by examining and promoting improvements in separation practices and establishing shared reduction measures at individual business locations.

Generation of Hazardous Waste

We are working to reduce emissions of hazardous wastes, such as strong acids, strong alkalis, and flammable waste oil, that are considered to put a heavy burden on the environment. We define hazardous waste in Japan as "specially controlled industrial waste" and overseas in accordance with the laws and regulations of each country.

In fiscal 2024, we generated 956 tons of hazardous waste in Japan, consisting of 0 tons for direct landfill, 247 tons for intermediate treatment, and 709 tons for recycling. Overseas, we generated 10,156 tons (including 267 tons for direct landfill, 8,708 tons for intermediate treatment, and 1,181 tons for recycling). One of the ways we are reducing hazardous waste is by using sodium aluminate, a type of strong alkali emitted from the extrusion process, as a neutralizer for wastewater treatment at paper mills.

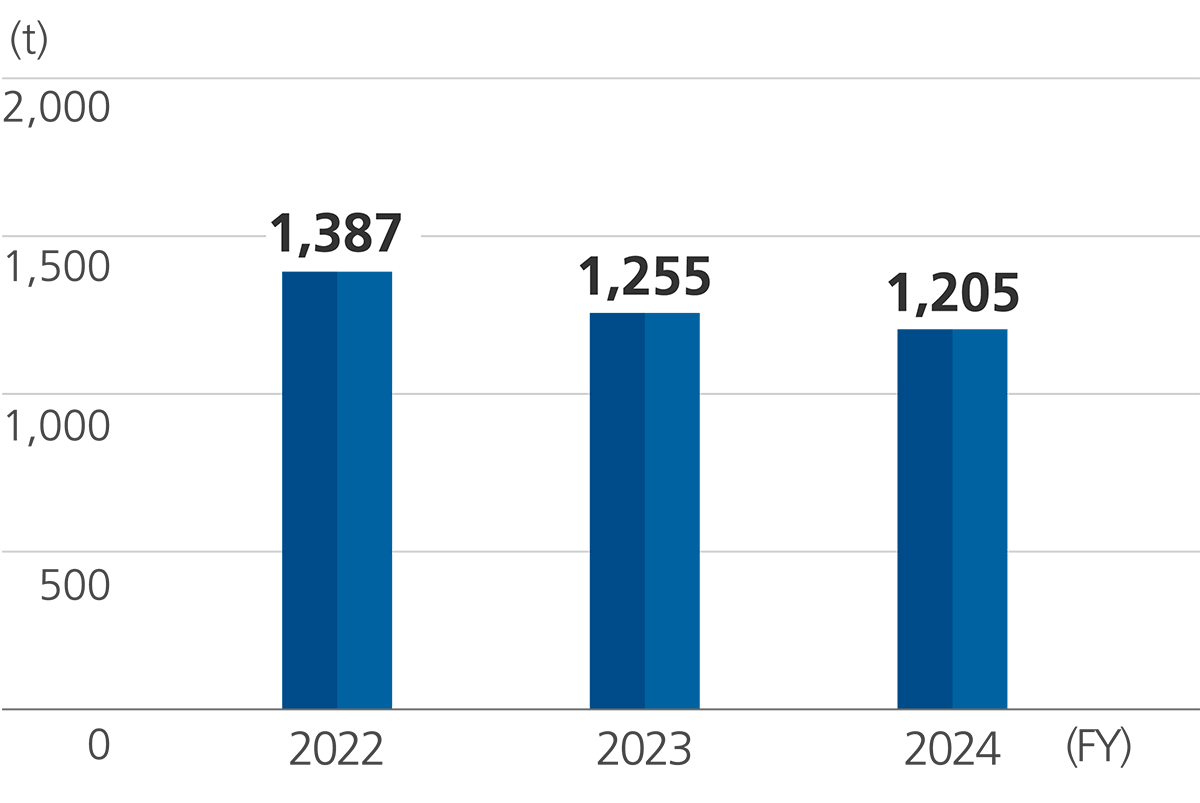

Reducing Amounts of Waste Plastic Generated

Packaging materials, such as polyethylene sheets used for shipping products, are increasingly being treated as industrial waste, especially after China stopped importing waste plastic several years ago. One of the ways we are reducing the amount of plastic used for our products is by working with our business partners to use thinner packing sheets. These and other efforts have helped us minimize the amount of waste plastic classified as industrial waste. We are also planning to increase the recycling of waste plastic in response to the growing societal demand, especially following the adoption of the Act to Promote the Recycling of Plastic Resources in April 2022.

Waste Plastic Production Volume (Japan)

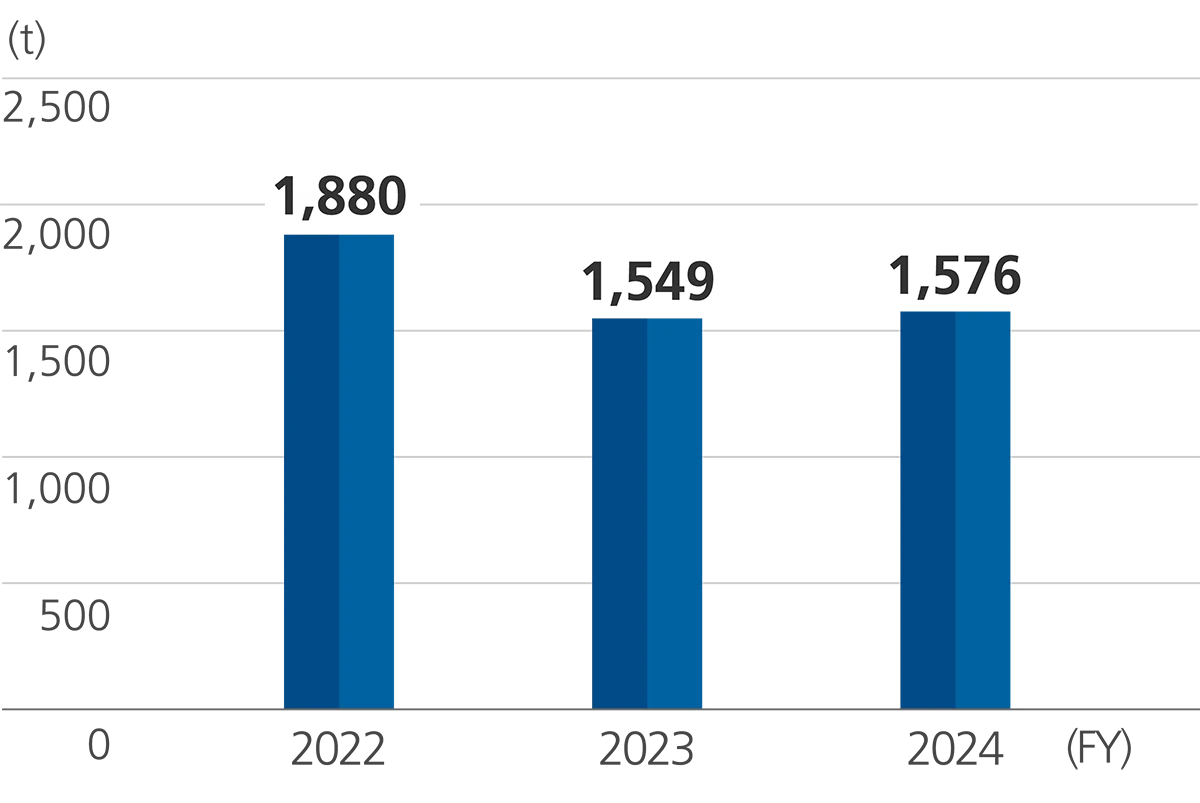

Reduction of Wood Waste

We promote the reuse, recycling, and conversion to other materials of wood used in our product materials and product packaging. Wood used to be the primary packaging material for some of our products, but because the wood materials were not recyclable and became industrial waste, we reengineered the packaging to use corrugated paper, for which recycling has become common.

Amounts of Wood Waste Generated

Thermal Recycling of Packing Materials

We contract the handling of our waste plastics—such as protective sheets and binding bands for products used as packaging materials—to waste disposal companies that utilize these materials for thermal recycling (energy recovery). This includes use as a fuel source for incinerators that primarily generate electricity from waste materials.

Activities Aimed at Reducing Office Waste

At UACJ, individual offices actively work to protect the environment by separating waste (such as separating paper from plastic) and segregating materials for recycling (including newspapers, copier paper, magazines, and cardboard).