Flat Rolled Products

ALmitas+ U-ALight 6 Series (6000 Series Alloys)

- HOME

- Products

- Flat Rolled Products

- ALmitas+ U-ALight 6 Series (6000 Series Alloys)

6000 series alloy sheets for body panels that excel in formability and display high strength after coat-baking

U-ALight is a new aluminum product series based on our conventional automotive products with the added benefit of lower environmental impact.

Features

- UACJ offers a wide selection of 6000 series alloys that combine strength, formability, weldability, corrosion resistance, and high surface quality required of automotive panel materials.

- Highly bake-hardenable U-ALight 6S is recommended for parts where dent resistance is critical.

- U-ALight 6HF exhibits high ductility (elongation) and is recommended where formability is critical.

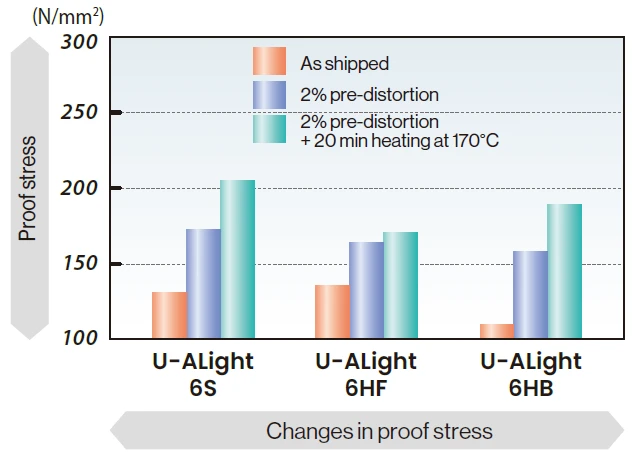

- Bake hardenability: the ability to remain low in strength during machining; then strength is increased by the heat of coat-baking.

Mechanical properties

(Sheet thickness: 1 mm)

| Model | AA*1designation | Tensile strength(N/mm²) | Proof stress(N/mm²) | Elongation(%) | Proof stress after baking*2 (N/mm²) |

|---|---|---|---|---|---|

| U-ALight 6S | 6116 | 240 | 130 | 28 | 205 |

| U-ALight 6HF | 6116 | 245 | 135 | 30 | 170 |

| U-ALight 6HB | 6005 | 210 | 110 | 27 | 190 |

- AA: The Aluminum Association (USA); the numbers show equivalent alloys.

- Baking conditions: Test values after application of 2% pre-distortion and 20-min heating at 170℃

Formability

(Sheet thickness: 1 mm)

| Model | Formability | Hemmability | Corrosion resistance | BH effect | Ridging resistance |

|---|---|---|---|---|---|

| U-ALight 6S | ○ | ○ | ○ | ○ | ○ |

| U-ALight 6HF | ○+ | ○ | ○ | △ | ○ |

| U-ALight 6HB | ○ | ○+ | ○ | ○ | ○ |

- standard △ ⇒ ○ ⇒ ○+

Bake hardenability

(Sheet thickness: 1 mm)

| Model | 2% pre-distortion + 20 min at 170°C | ||

|---|---|---|---|

| Tensile strength (N/mm²) | Proof stress (N/mm2) | Elongation (%) | |

| U-ALight 6S | 285 | 205 | 23 |

| U-ALight 6HF | 275 | 170 | 23 |

| U-ALight 6HB | 270 | 190 | 22 |

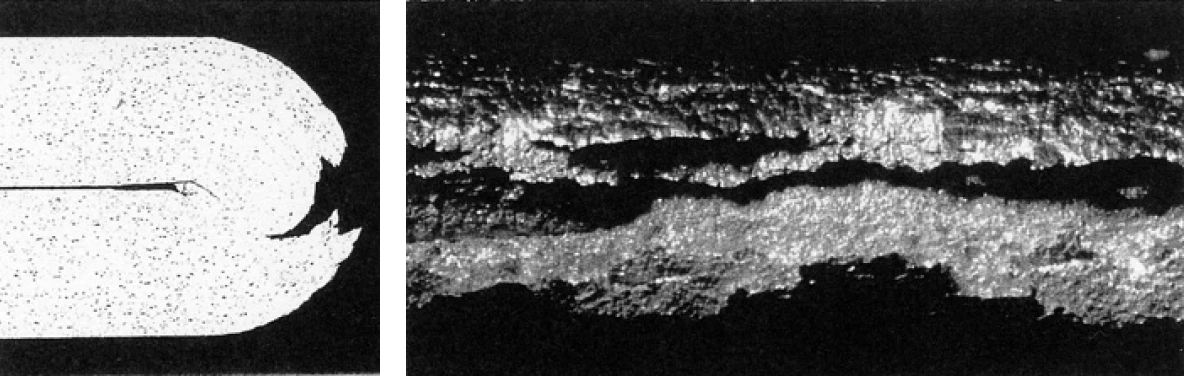

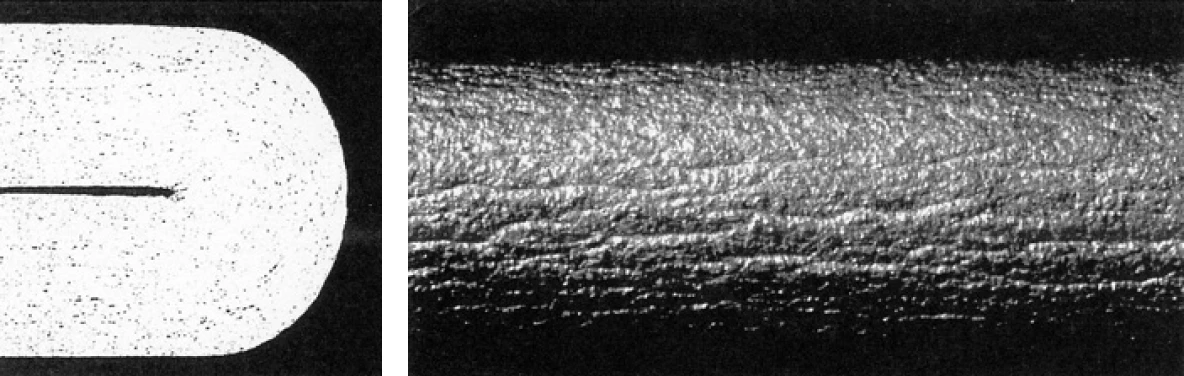

Hemmability

Ordinary body sheet

High-hemmability sheet

than flat hemming.