Flat Rolled Products

ALmitas+ Alnovi (superplastic aluminum alloy sheets)

- HOME

- Products

- Flat Rolled Products

- ALmitas+ Alnovi (superplastic aluminum alloy sheets)

Freely formable like plastic

Features

- Using Alnovi, a product can be built as one piece, which reduces the number of parts and welds.

- Only a one-sided die is required, reducing the die cost.

- The material can be formed into a complex shape or flexible design, thanks to its excellent shape retention (no springback).

Features of Alnovi

Exhibits high strength with tensile strength of 285 N/mm2 and proof stress of 140 N/mm2 (comparable to A5083-O), excellent corrosion resistance of the Al-Mg alloy base, and outstanding weldability.

Comparison between press forming and blow forming

| Item | Press forming | Blow forming |

|---|---|---|

| Forming temperature | Normal temperature | Approx. 500°C (heating die + material) |

| Forming time (strain rate (/s)) | Several seconds (1 to 10) | Several to tens of minutes (0.01 to 0.001) |

| Changes in sheet thickness | Little change | Large decrease in thickness |

| Productivity | Suitable for mass production | Suitable for small-lot production Little springback |

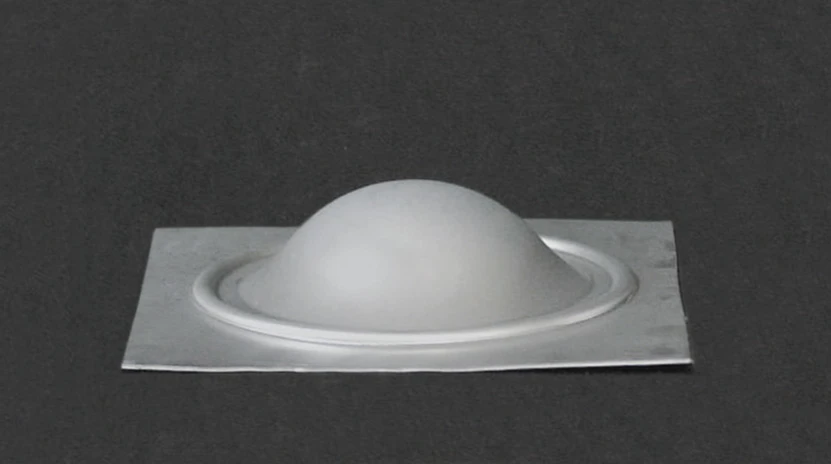

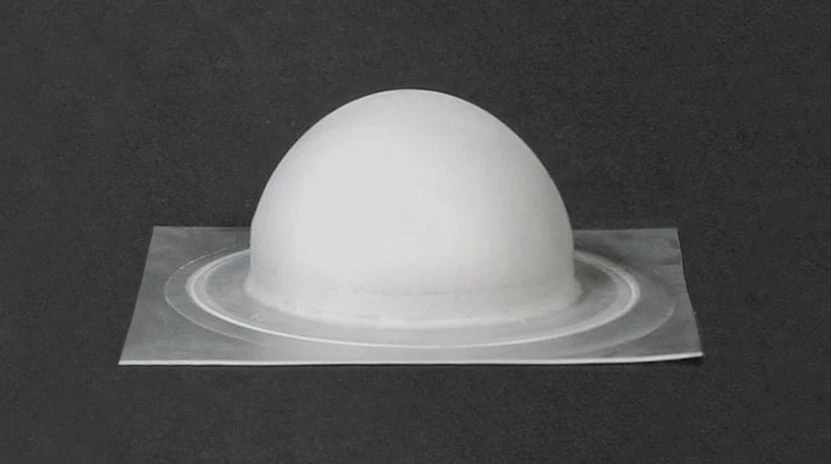

| Formability test |

|

|

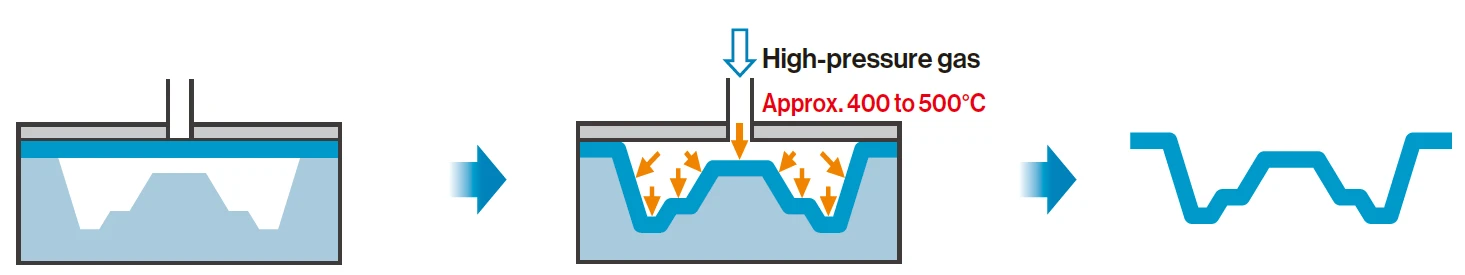

Flow of blow forming

Lineup

| Alnovi-1 | This is a superplastic alloy that leverages the advantages of JIS A 5083P, a class of alloys for medium-strength structures widely used in automobiles, trains, ships, and many other structures. The material has the following features.

|

|---|---|

| Alnovi-U | A new-specification superplastic alloy developed to enable low-temperature, high-speed blow forming and build high-strength products. |

| Alnovi-S | A cost-effective superplastic alloy based on Alnovi-U |

Mechanical properties

| Model | Tensile strength (N/mm2) |

Proof stress (N/mm2) |

Elongation (%) |

|---|---|---|---|

| Alnovi-1 | 275 to 350 | 125 to 200 | 16 to |

| Alnovi-U | 295 to 370 | 135 to 210 | 16 to |

| Alnovi-S | 295 to | 150 to | 16 to |