Feature 2: Contributing to Thailand's economy

ThailandPassing down technical skills

Contributing to Thailand’s development by transferring UACJ’s advanced manufacturing capabilities

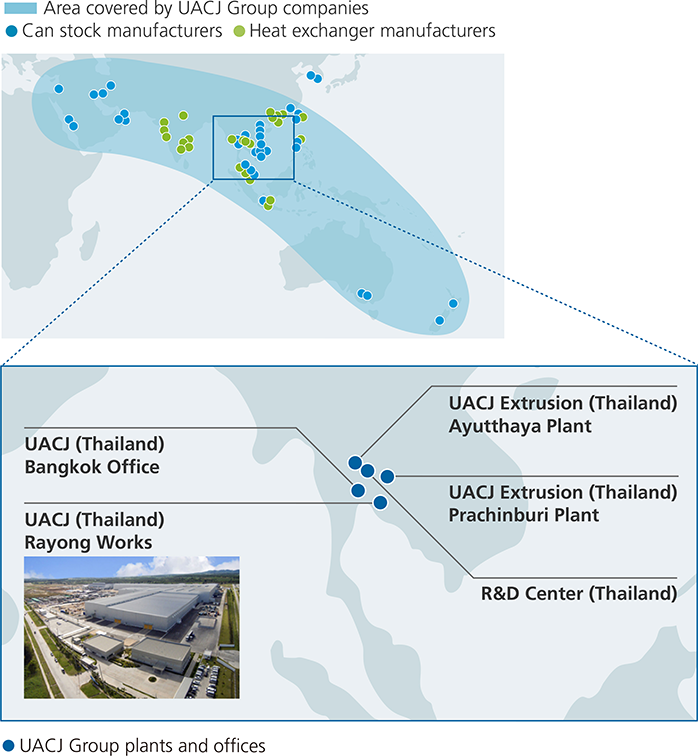

In Thailand, a country undergoing rapid economic growth, two companies of the UACJ Group manufacture aluminum materials and producsts as key suppliers in Southeast Asia. While meeting growing demand in the region, the Group is contributing to Thailand’s economy, providing employment opportunities, and developing the skills of workers.

UACJ Group contributionsContributing to Thailand’s economy

High-quality aluminum products help drive Thailand’s development

In Thailand, advanced industrial development is being promoted based on Thailand 4.0, a long-term economic model promoted by the Thai government. Aluminum is expected to be a key material for several of the 10 industries designated as important under the initiative, including next-generation vehicles, smart electronics, aerospace, and logistics. In the Southeast Asian market as a whole, demand for aluminum used for can stock and automotive heat exchangers is projected to grow as population and economic growth drive up personal consumption.

In 2015, UACJ (Thailand) Co., Ltd., established Rayong Works in Amata, a city in the province of Rayong, as Southeast Asia’s first flat-rolled aluminum manufacturing facilities integrating all processes from casting to finishing. Since then, the factory has been supplying aluminum products to countries all over Asia. Amid rising demand in the canned beverage and automotive markets, the company steadily boosted annual production capacity to 320,000 tons by the autumn of 2019, making it a leading supplier in the region.

Meanwhile, UACJ Extrusion (Thailand) Co., Ltd., has been manufacturing aluminum materials for automotive heat exchangers at its Ayutthaya Plant and Prachinburi Plant, and supplying the products to the Asian factories of European automakers. The Prachinburi Plant is now planning to boost monthly production capacity to 600 tons in the near future.

While meeting demand from Asian countries, UACJ (Thailand) is also supplying products to the Middle East and Australia, and UACJ Extrusion (Thailand) has broadened its customer base to Mexico and Brazil, contributing to greater exports from Thailand.

UACJ Group contributions Creating local employment

Recruiting and appointing employees to locally operate factories

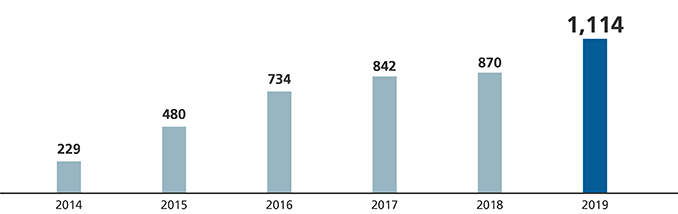

UACJ recognizes the importance of hiring locally based workers to operate its factories. In line with this approach, UACJ (Thailand) has steadily increased the number of Thai employees since it began operating in 2014, and the total surpassed 1,000 employees in May 2019. In the future, UACJ’s goal is to have its factories in Thailand run entirely by workers hired in Thailand.

When UACJ completes its third phase of investment in UACJ (Thailand)’s production facilities, they will be about the same size as UACJ’s main factories in Japan. Preparations are being systematically undertaken to enable Thai employees to operate the facilities and lay the foundations for a domestic aluminum product manufacturing industry. In recent years, for example, Thai employees have been assigned to manage safety, an essential task at the factories. With the expansion of the factories, operating manuals for newly installed equipment are being created and inspections and follow-ups are being carried out to ensure the safety of employees.

UACJ Extrusion (Thailand) began operating several years before UACJ (Thailand), and its Thai employees already handle most operations of the Ayutthaya and Prachinburi plants. In recognition of this achievement, senior officials from the Thai government met with UACJ’s executive officers in July 2018 and conveyed their support for the UACJ Group’s business activities and hope for further investment in Thailand going forward.

* Annual figures are as of May 31

UACJ Group contributionsDeveloping human resources

Passing down UACJ’s capabilities and improving employees’ skills

Positioning human resources development as central to its business, UACJ works to improve the capabilities of employees and raise their productivity in order to enhance the market competitiveness of its products. It also recognizes that refining the skills of workers can contribute to their country’s development over the long term.

When UACJ’s two subsidiaries in Thailand began operating, skilled engineers were sent from Japan to coach the local employees and provide on-the-job training. Operational manuals were produced in Japanese, Thai and English, and detailed training programs covered work procedures as well as the underlying objectives of the procedures. While teaching the local employees about the quality and spirit of manufacturing that UACJ has refined in Japan, the instructors also adapted the work processes to Thai culture and the viewpoints of the employees.

With the ongoing transfer of technology to UACJ Extrusion (Thailand), the local employees have continuously found innovative ways to improve production lines. In recent years, UACJ (Thailand)’s newly recruited employees have been gaining skills and knowledge through a three-year training program at UACJ’s R&D Center in Japan.

In addition, UACJ established the R&D Center (Thailand) in October 2018, the Group’s third such facility in addition to those in Japan and the United States. Led by employees who received technical training in Japan, the new facility is aiming to generate innovations by collaborating with both UACJ (Thailand) and UACJ Extrusion (Thailand), as well as public organizations and universities.

Safety training leads to 600 consecutive accident-free days

I joined the company in 2016 and currently serve as a senior manager of the Safety Department. In August 2019, we achieved 600 consecutive accident-free days at our factory thanks to the Japanese engineers who assisted our safety management over the years. That accomplishment was not easy, and it attests to the refined skills of our local employees. The UACJ Group pays close attention to manufacturing and quality, so we want to keep maintaining safety at UACJ (Thailand) based on that corporate culture.

Senior manager, Safety Department

UACJ (Thailand) Co., Ltd.

Growing together with the company as a manager

I joined the company in 2013 with the hope of advancing my career in procurement at a large corporation. Now I am a senior manager supervising 13 subordinates. Procurement is closely linked to factory production schedules and profitability, so we must take great care in our work. Everyone on my team recognizes the importance of that, and works to contribute to the growth of UACJ (Thailand) while refining our individual skills. Other female managers work in the accounting and finance departments, so I think we have a culture of gender equality in the company.

Senior manager, Procurement Department

UACJ (Thailand) Co., Ltd.