Sheet and foil rolling technology

- HOME

- Technology and R&D

- Equipment and Production Technology

- Sheet and foil rolling technology

Rolling technology supporting high quality and productivity

Plate is produced by flat rolling—a processing method in pair of parallel rollers is rotated to turn an aluminum ingot, called a slab, into a thinner product, a plate.

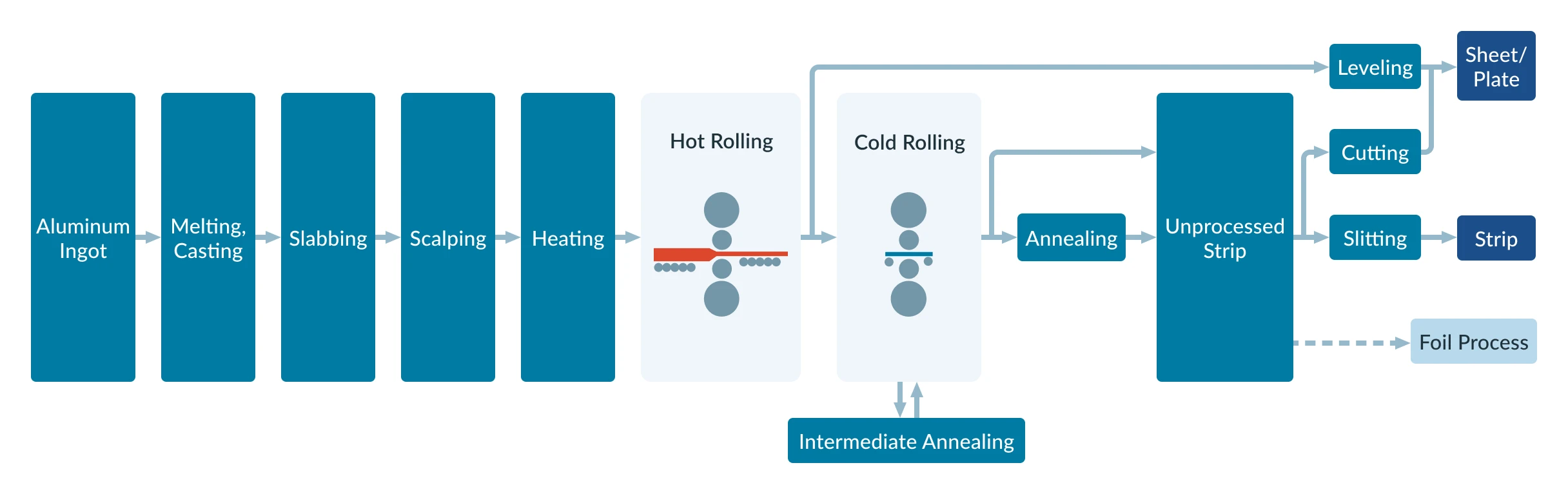

Flat rolling manufacturing process

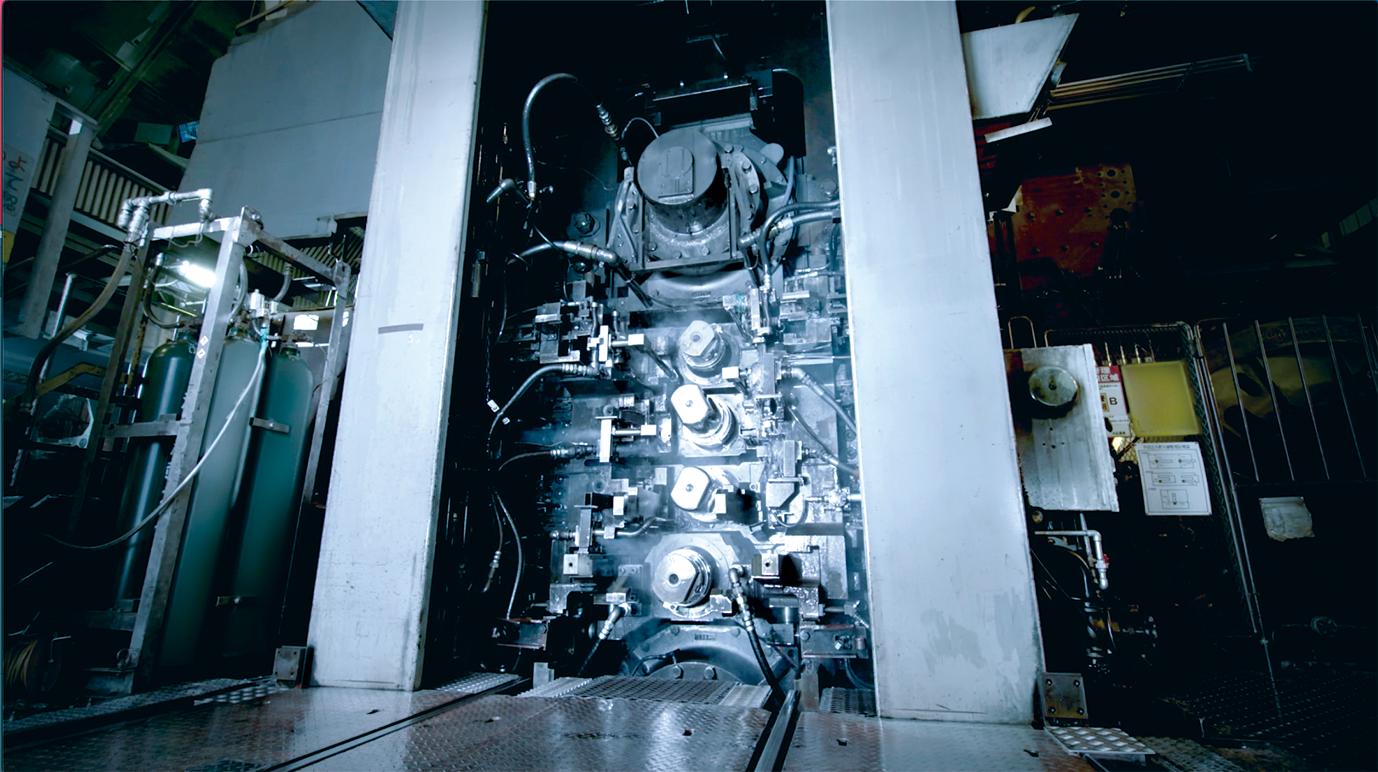

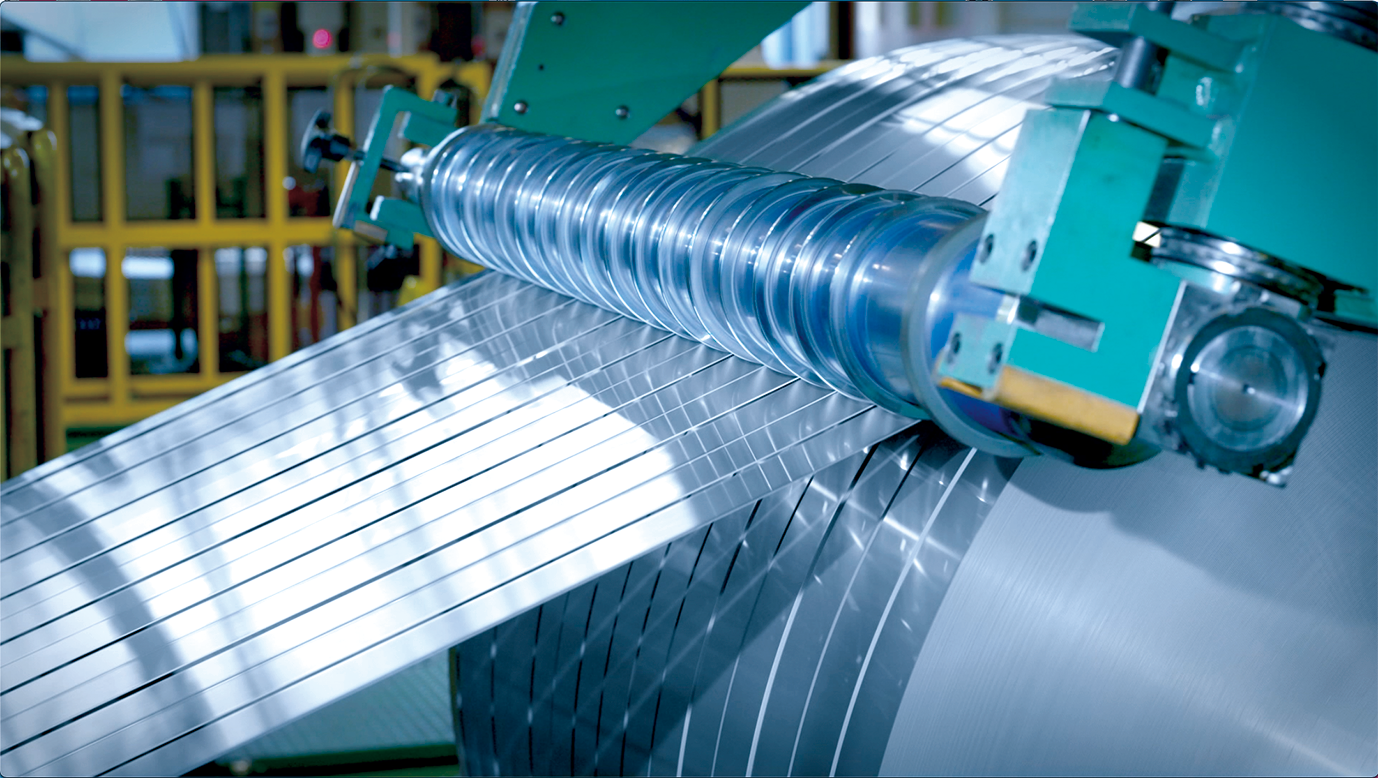

Our high-speed rolling capabilities achieve the ultimate in shape and thickness accuracy.

We manufacture high-quality aluminum products to meet increasingly diverse and sophisticated customer requirements by making full use of our world-class technology.

Products and applications that utilize flat rolled aluminum are ubiquitous, including packages, caps, cans, household utensils, roofs, building interiors and exteriors, outer packages, freezing, refrigeration, home electric appliances, aircrafts, subways, and bullet train cars. We have purchased state-of-the-art computerized production equipment for automatic flatness control (AFC), automatic board thickness control (AGC), and other advanced features. Such equipment enables us to respond to increasingly diverse and sophisticated customer needs. By significantly expanding our production range and employing advanced produciton technology, we are striving to improve the quality and precision of aluminum products and ensure their stable supply.

Melting & Casting

Through melting, chemical composition adjustment, and molten metal treatment, liquid aluminum is poured into slabs (long-rectangle ingots) for coils and plates.

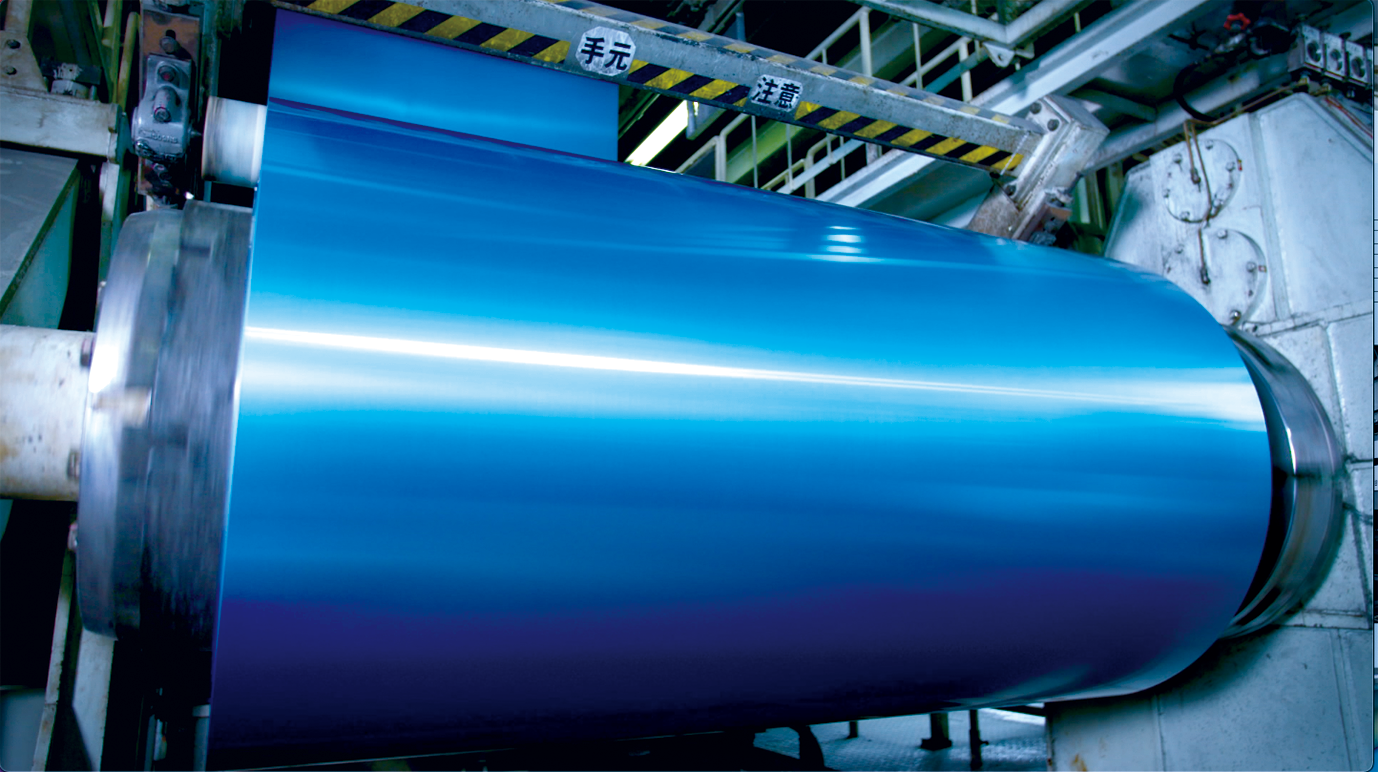

Hot Rolling

Cast slabs are milled, heated, and rolled into coils. Rolling processes include hot rough rolling, hot finishing rolling, and cold rolling. We possess the world’s fastest rolling mill.

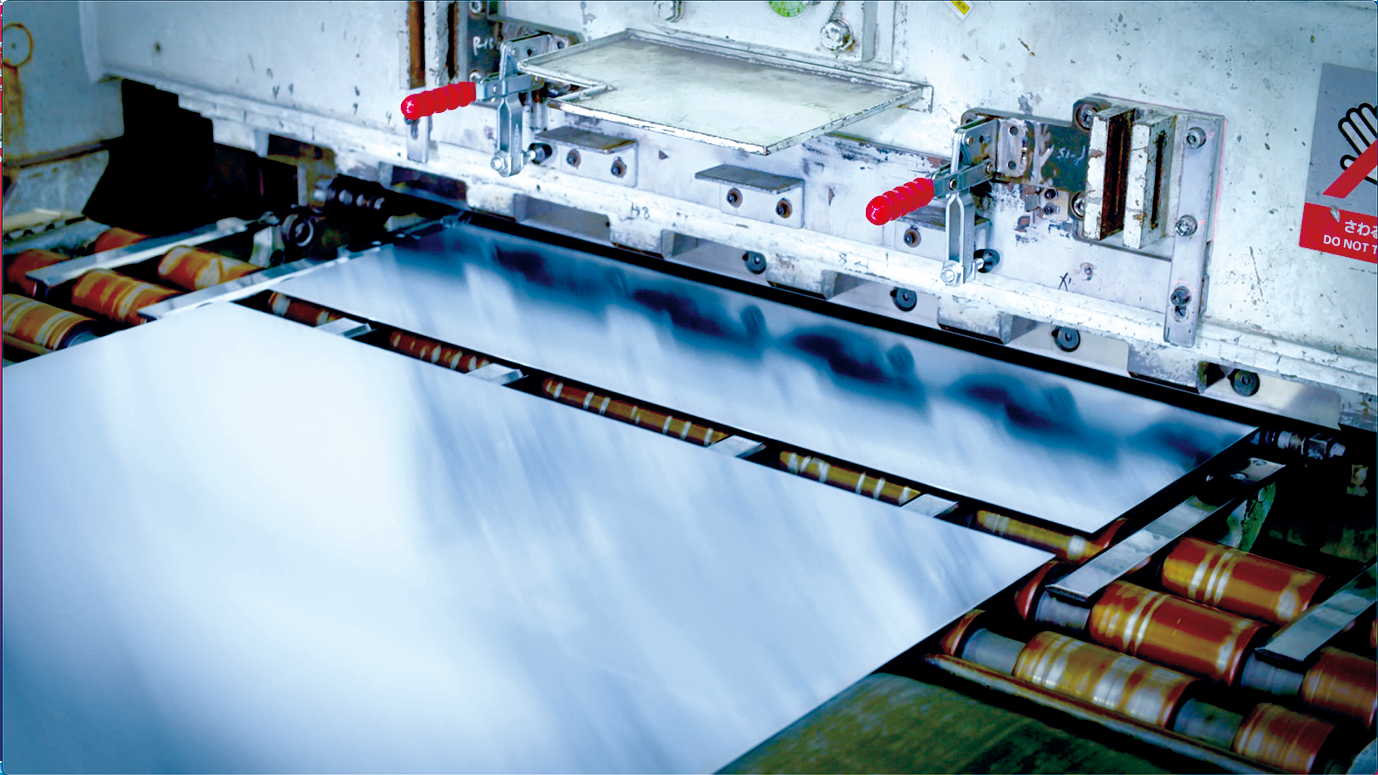

Finishing

Through finishing processes such as surface treatment, straightening, and cutting, we deliver aluminum products to our customers.

Thin-plate

Thick Plates

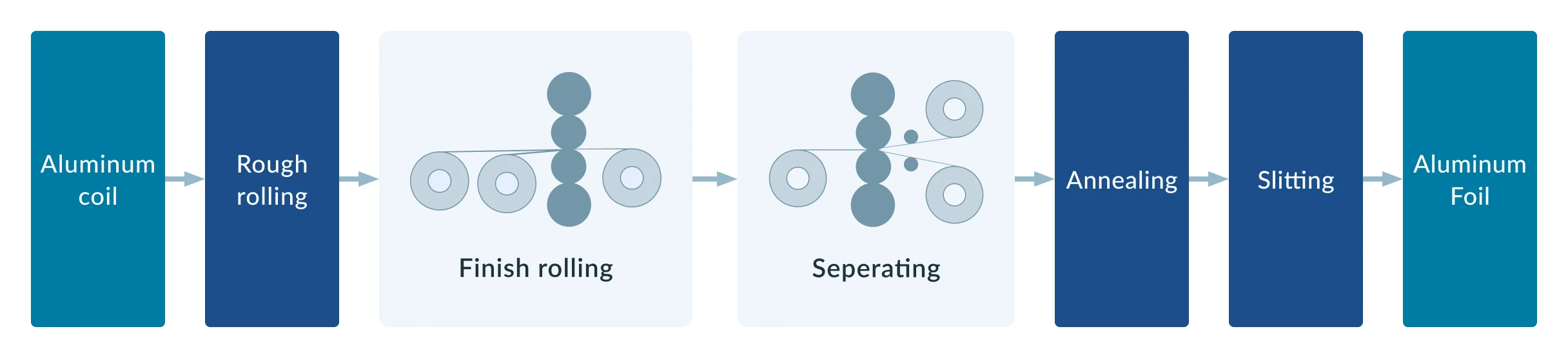

Foil manufacturing process

UACJ Foil produces high-quality products due in large part to stringent hygiene management for all processes (from import of base foil to manufacturing and shipping) and computer-assisted quality controls.