Forging technology

- HOME

- Technology and R&D

- Equipment and Production Technology

- Forging technology

High-strength and reliable large aluminum forged products for all fields

UACJ Corporation was the pioneer in Japan to engage in making aluminum forged products, and for many years contributed to the development of aviation and space technology. In addition to the aerospace sectors high strength, reliable large aluminum forged products are also used more and more in high speed railways, and semiconductor manufacturing equipment and ships.

UACJ Corporation is the world’s top-class integrated aluminum manufacturer. It meets various customer expectations by manufacturing high quality forged and cast aluminum products under an integrated system that incorporates every stage from the R&D of aluminum materials to ingots, tempering, and finishing.

Forging features

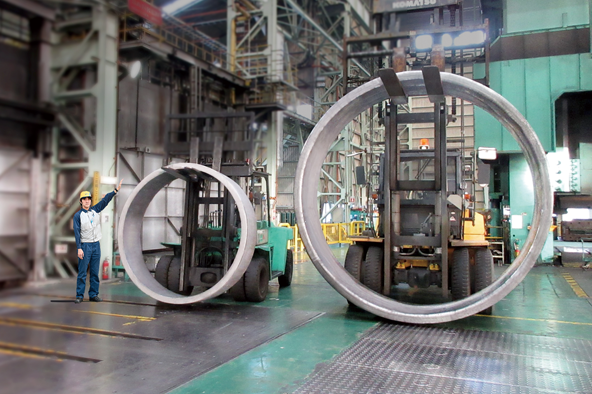

Foundry & Forging Works manufactures forged products such as important components to support highspeed train axles produced by die forging the strongest aluminum alloys, frames for aircraft fuselages, wall rings for space rockets that thoroughly reduce the residual stress, and Highspeed rotation supercharger fans for ships.

We have expanded the potential of aluminum by pursuing technological innovation and functionality in these products.

With a 15,000metric ton forging press, one of the largest in Asia, that can produce forged products up to 6 tons in weight, it is fully prepared to meet any customer r equest.

- Enabling forging of large products using 15,000-metric ton forging press

- Enabling high quality products using large heat treatment furnace

- Enabling integrated production from forging to machine processing

ton forging press

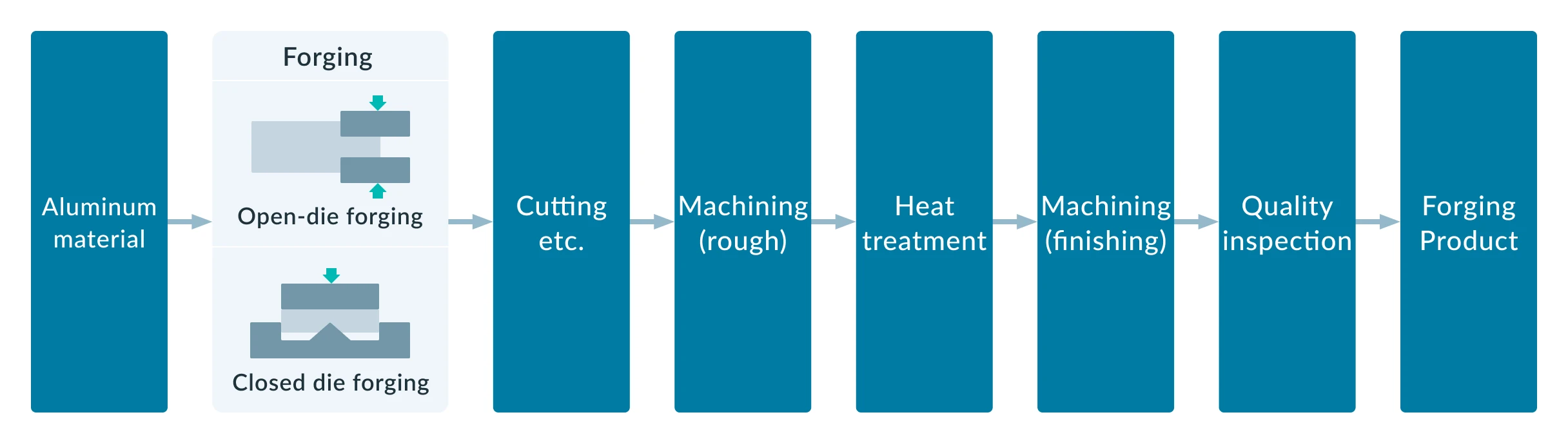

Types of forging technology

UACJ uses two types of forging processes: open die forging to shape an ingot while pressing, and closed die forging to form a shape using a die. We serve diverse needs to fulfill different product purposes and customer requests.

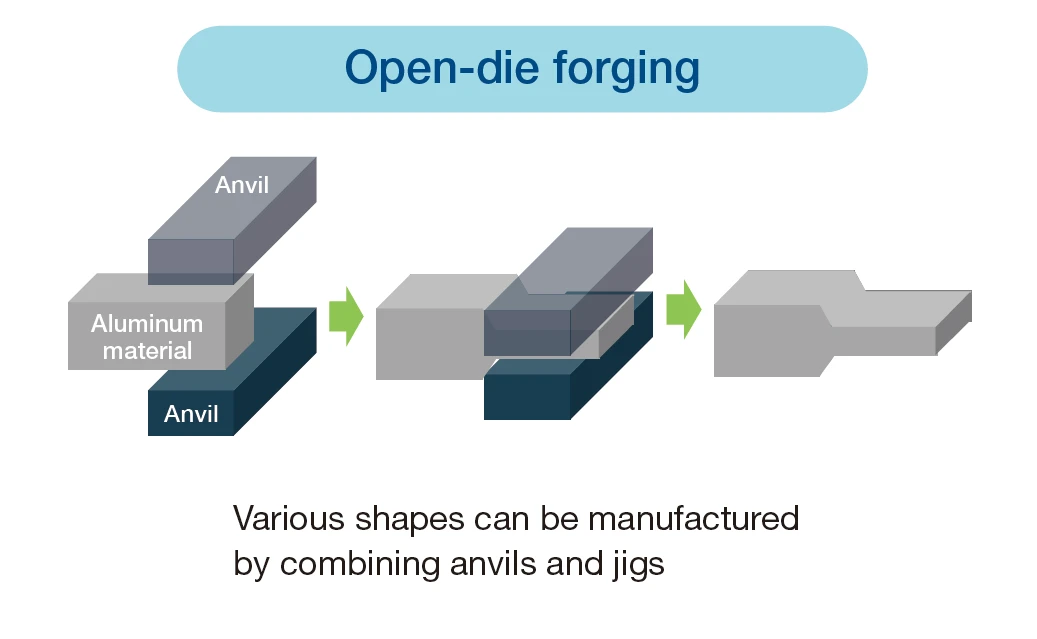

Open-die forging

Hand forging is suitable for large-scale and small-quantity

production because it is not confined to specific dies

Our hand forging is making Aluminum ingot into many differed forms by repeating pressure in certain areas using press and tools. This is suitable for products which cannot use dies such as large-scale and small-quantity products.

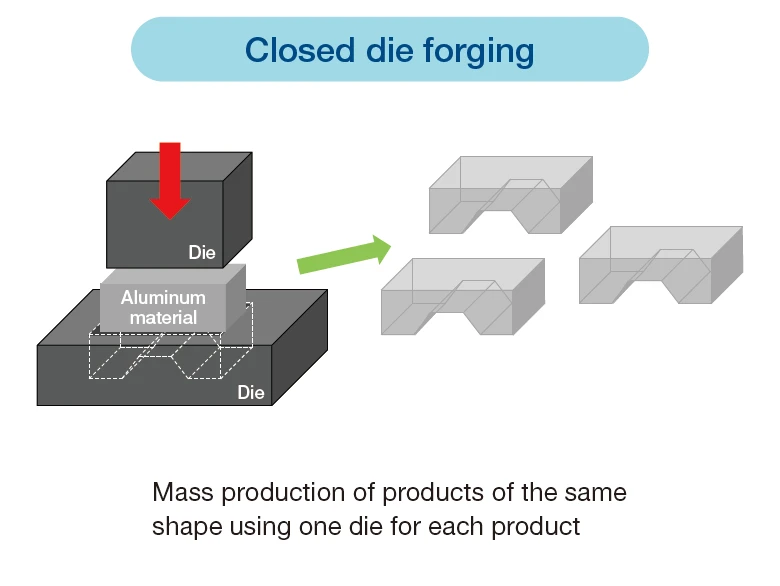

Closed die forging

Forging using dies similar in shape to the final product

This forging method uses dies shaped almost like the final product, making it possible to minimize the machining process or omit it altogether. It is suitable for mass production because it produces few variations in quality or size discrepancies.

Forging process

Under an all-in-one production system from aluminum material development to ingot casting, tempering, and finishing, we manufacture high-quality forged and cast aluminum products to meet customers’ expectations.