Chemical Substance Management and Pollution Prevention

- HOME

- Sustainability

- A Future where the Earth can Continue to be Beautiful and Bountiful

- Chemical Substance Management and Pollution Prevention

Our Approach

The UACJ Group strives to properly manage chemical substances and control emissions while also switching to chemicals with low impacts on the environment and human health. We do this out of concern not only for effects on the natural environment but also for safety - for employees engaged in manufacturing our products and customers when they use our products. In our efforts to control emissions, we have established and abide by our own standards, which are stricter than those set forth in Japan’s Air Pollution Control Law, Water Pollution Control Law, local government ordinances, and conventions.

Fiscal 2024 Results

Pollutant Control at Individual UACJ Works (Fiscal 2024)

○: Measurements fall within standards

| Measurement Item | Nagoya Works (incl. Extrusion Div) |

Fukui Works |

Fukaya Works |

Oyama Works |

Foundry & Forging Works |

|

|---|---|---|---|---|---|---|

| Air | NOx, SOx, soot and dust | 〇 | 〇 | 〇 | 〇 | 〇 |

| Water | pH, BOD | 〇 | 〇 | 〇 | 〇 | 〇 |

| n-H (mineral oil), SS | 〇 | 〇 | 〇 | 〇 | 〇 | |

Control of PRTR Substances

The UACJ Group seeks to reduce pollutants by utilizing the Pollutant Release and Transfer Register (PRTR) system*1 based on the Act on the Assessment Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement* to ascertain and disclose the amounts of substances handled, released, and transferred in its operations.

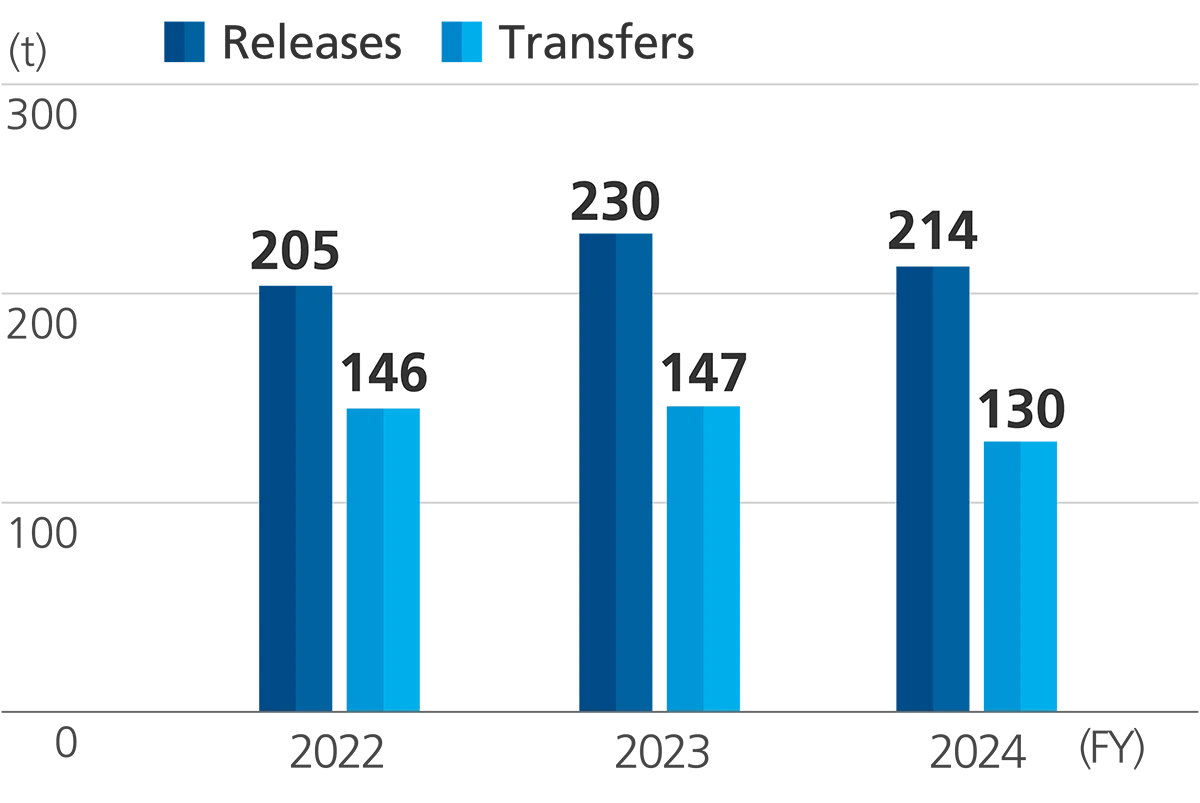

In fiscal 2024, with the increase in production volume from fiscal 2023, the handling volume increased by 43 tons (1.4%), but the group's overall emissions and transfers, across all target substances, have decreased by 26 tons (7%) and 17 tons (12%), respectively.

- The PRTR system requires businesses handling chemical substances that are potentially hazardous to human health and the environment to estimate the amounts of chemical substances released from business sites into the environment (air, water, and soil) and transferred in waste, and report the data to the local governments. The governments then compile the reported data and estimates and publish the emission and transfer volumes.

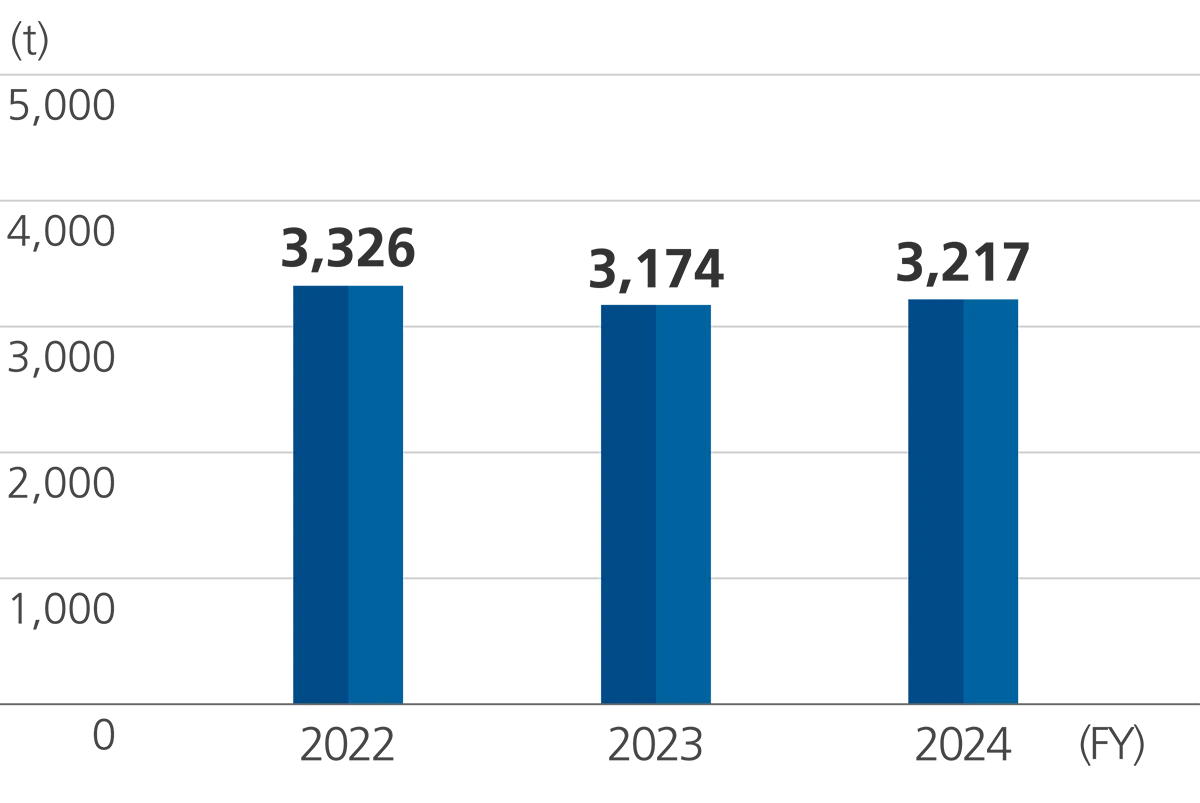

Amounts of PRTR Substances Handled

- (Contain manganese, chromium, nickel, and lead as alloy substances)

Amounts of PRTR Substances Released or Transferred

- Measurement scope: UACJ (Nagoya, Fukui, Fukaya, Nagoya(Extrusion), Oyama, Foundry & Forging) , UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum), UACJ Extrusion Anjo Corporation, UACJ Extrusion Gunma Corporation, UACJ Extrusion Shiga Corporation, UACJ Foil Corporation (Isesaki ,Shiga, Nogi)

- Companies and sites as of September 30, 2025.

Handling, Releases, and Transfers of PRTR Substances (Fiscal 2024)

| No. | Substance | Amount Used (kg) | Amount Released (kg) | Amount Transferred (kg) |

|---|---|---|---|---|

| 412 | Manganese and its inorganic compounds | 1,728,143 | 0 | 15,399 |

| 300 | Toluene | 518,639 | 30,290 | 44,058 |

| 80 | Xylene | 179,606 | 18,019 | 1,325 |

| 87 | Chromium and chromium(III) compounds | 174,879 | 15 | 26,644 |

| 594 | Ethylene glycol monobutyl ether*2 | 139,545 | 4,860 | 1,063 |

| 691 | Trimethylbenzene*2 | 128,203 | 80,400 | 1,124 |

| 273 | 1-dodecano | 112,977 | 65,470 | 23,311 |

| 53 | Ethylbenzene | 77,033 | 2,077 | 734 |

| 627 | Diethylene glycol monobutyl ether*2 | 60,395 | 1,891 | 397 |

| 737 | Methyl isobutyl ketone*2 | 15,607 | 333 | 55 |

| 308 | Nickel | 15,527 | 0 | 0 |

| 88 | Hexavalent chromium and its compounds | 14,844 | 0 | 31 |

| 374 | Hydrogen fluoride and its water-soluble salts | 13,584 | 1,214 | 10,905 |

| 302 | Naphthalin | 8,063 | 202 | 41 |

| 407 | Poly (oxyethylene) = alkyl ether | 4,821 | 4,733 | 40 |

| 207 | 2,6-Di-tert-butyl-4-cresol | 4,694 | 1,714 | 2,914 |

| 321 | Vanadium compounds | 3,159 | 0 | 0 |

| 392 | n-hexane | 3,157 | 599 | 1,165 |

| 1 | Water-soluble zinc compounds | 2,565 | 0 | 0 |

| 394 | Beryllium and its compounds | 1,262 | 0 | 0 |

| 595 | Ethylenediaminetetraacetic acid and its potassium and sodium salts*2 | 1,149 | 1,132 | 6 |

| 57 | Ethylene glycol monoethyl ether | 1,140 | 35 | 8 |

| 697 | Lead and its compounds*2 | 1,046 | 0 | 0 |

| 3,210,039 | 212,945 | 129,220 |

- Measurement scope: UACJ (Nagoya, Fukui, Fukaya, Nagoya(Extrusion), Oyama, Foundry & Forging) , UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum), UACJ Extrusion Anjo Corporation, UACJ Extrusion Gunma Corporation, UACJ Extrusion Shiga Corporation, UACJ Foil Corporation (Isesaki ,Shiga, Nogi)

- Companies and sites as of September 30, 2025.

- Substances subject to the PRTR Law revisions

Reducing VOC Releases

The UACJ Group has designated toluene, xylene, ethylbenzene, and trimethylbenzene as substances to be reduced and is taking steps to reduce atmospheric emissions of volatile organic compounds (VOCs).

The Group’s exhaust gas treatment systems, including the deodorizing equipment at Utsunomiya Color Aluminum Works installed in the previous year, sustained the low level of atmospheric emissions in fiscal 2023. Progress was also made toward incorporating an alternative substance for paint thinner.

Prevention of Air Pollution

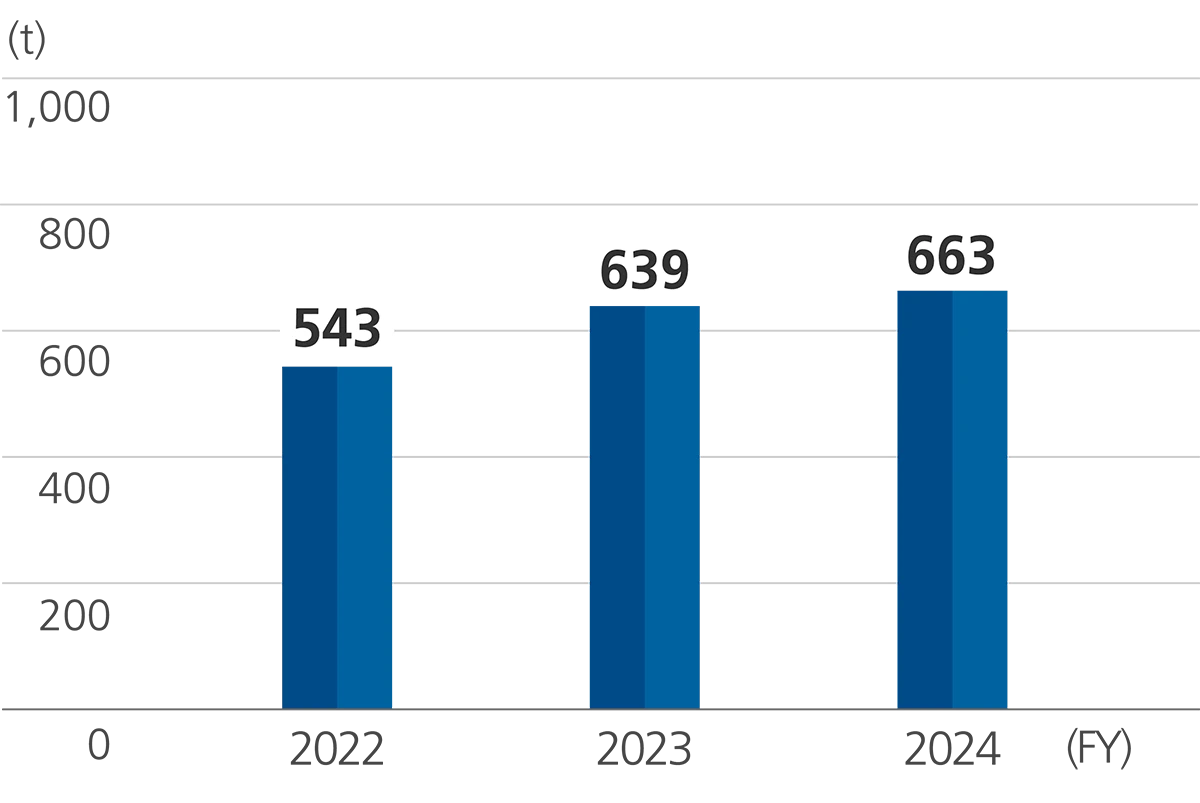

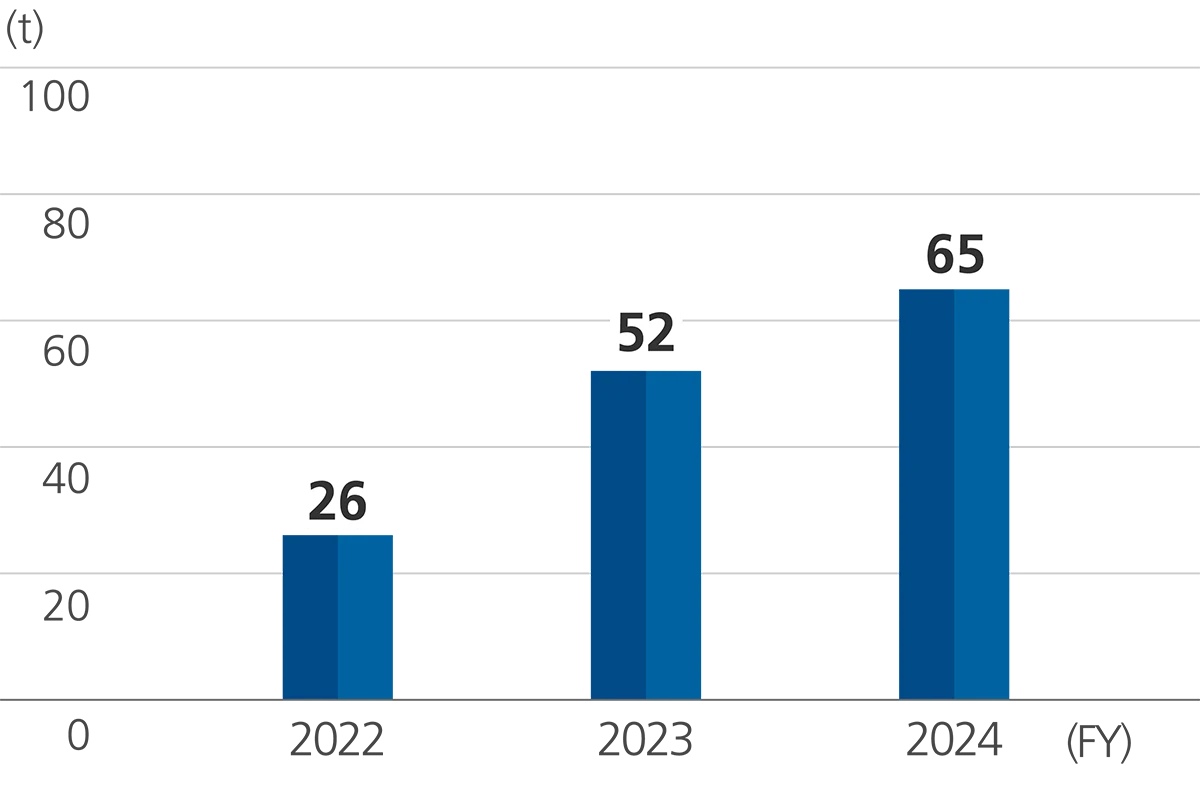

The UACJ Group is seeking to reduce emissions of air pollutants by maintaining and managing plant facilities and by converting fuel sources from heavy oil to LNG. Efforts to date are enabling the Group to maintain low levels of SOx and NOx emissions.

NOx Emissions

SOx Emissions

- Measurement Scope: UACJ (Nagoya, Fukui, Fukaya, Oyama)

- Companies and sites as of September 30, 2025.

Control of PCBs

In accordance with Japan's Act on Special Measures concerning Promotion of Proper Treatment of PCB Wastes (PCB Special Measures Law) (PCB: polychlorinated biphenyls), the UACJ Group conducts surveys at each business site, develops replacement plans, and advances the replacement and removal of targeted electrical items. Removed items are properly stored, managed, and disposed of.

Addressing the Problem of Asbestos

The UACJ Group records the history of asbestos use, examines the current status, and implements measures to reduce asbestos in its products, factory buildings, equipment, and fixtures. The Group has never used asbestos in its product or sold products that contain asbestos.

Regarding the buildings, sprayed asbestos, used in a small portion of buildings and posing a high scattering risk, was fully removed in fiscal 2024.

When regularly scheduled inspections are conducted, we are replacing equipment and fixtures with low asbestos risk with equipment and fixtures that do not contain asbestos.

Measures to Control Dioxins

The UACJ Group’s aluminum melting furnaces are categorized as “specified dioxin-emitting facilities” under the Act on Special Measures against Dioxins, and we strive to maintain the concentration of dioxins in exhaust gas below the regulatory levels.

We do this by maintaining the optimum amount of combustion air in the aluminum melting furnace and thoroughly controlling the input materials, thereby preventing the production of dioxins.

As required by law, we also inspect our aluminum melting furnaces for dioxins each year and report the results to the government. The dioxin inspections in fiscal 2024 found levels below the legal requirements at all of our 24 designated air quality facilities and 2 designated water quality facilities.

Prevention of Water Pollution

The partially amended Water Pollution Prevention Act enforced in June 2012 requires the submission of notifications regarding hazardous substance in storage facilities, piping, and other areas as well as compliance with standards for structures and other facilities.

The UACJ Group completed the necessary actions at all operating sites prior to the end of the grace period on May 31, 2015.

Prevention of Soil and Groundwater Contamination

UACJ (Oyama works) and UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum) used specified hazardous substances in the past and are continuing with cleaning operations for contaminated groundwater. The companies’ monitoring of the effectiveness of their efforts are showing that the contamination levels are decreasing.

Measures Deal with Soil and Groundwater Contamination

| Business Location | Period | Contaminant | Response |

|---|---|---|---|

| UACJ (Oyama works) | Since fiscal 1999 | Tetrachloroethylene | Soil replacement, water extraction and purification |

| UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum) | Since fiscal 2004 | hexavalent chromium, fluorine | Soil replacement, water extraction and purification |

- Companies and sites as of September 30, 2025.