Environmental Management

- HOME

- Sustainability

- A Future where the Earth can Continue to be Beautiful and Bountiful

- Environmental Management

UACJ Group's basic environmental policy

Corporate Philosophy

The UACJ Group is thankful for the Earth’s abundance and life-supporting environment. Recognizing that the Earth is irreplaceable for all living things, we strive to protect the environment and create nature. We evaluate the environmental impact of current and future business activities across our supply chain, set concrete targets based on those evaluations, and take voluntary, proactive action to meet all laws and regulations and to minimize our impact and maximize our contribution to protecting the environment.

Guidelines

- We comply with environmental laws, regulations, and agreements, and institute our own standards for proper management of water, air, chemical substances, etc.

- We develop technologies and products that bring out the power of aluminum to minimize our impact and maximize our contribution to environmental preservation.

- We will contribute to achieving the goals of the Paris Agreement by advancing climate change initiatives and seeking to reduce greenhouse gas emissions across our supply chain.

- We take a leading role in driving a sustainable circular economy by promoting the recycling of aluminum and other primary and secondary materials.

- We work to conserve, restore, and enhance biodiversity, forests, and water resources, trying to pay back the value of ecosystems.

- We actively engage with stakeholders with the aim of living in harmony with nature and local communities.

Adopted August 2014

Amended March 2025

UACJ Corporation

Goals

UACJ Environmental Management Activity Policy

Slogan : We are grateful for the lush blue earth, and we will pursue aluminum to contribute to the formation of a sustainable society.

| Item | Indicator | FY2025 target | FY2030 target | |

|---|---|---|---|---|

| Eliminating serious environmental accidents | Number of serious environmental accidents | 1 or fewer | 0 | |

| Reducing industrial waste | Waste-plastic discharge per unit | 1% reduction vs. FY2024 | 25% reduction vs. FY2019 | |

| Promoting a circular economy for aluminum | UACJ recycling rate | 74.1% | 80% | |

| Addressing climate change | CO2emissions per unit | Scope 1・2 | 23% reduction vs. FY2019 | 30% reduction vs. FY2019 |

| CO2emissions per unit | Scope 3 | 17.4% reduction vs. FY2019 | 30% reduction vs. FY2019 | |

| Conservation, restoration, and creation of nature | Water withdrawal per unit | 22% reduction vs. FY2020 | 25% reduction vs. FY2020 | |

System

Environmental management system

Our company stipulates in its "Sustainability Policy" the basic philosophy and approach for promoting sustainability activities, including climate change measures. The "UACJ Group Basic Environmental Policies" (revised March 2025) also stipulates our environmental "Philosophy" and "Action Guidelines" (including circular economy, climate change measures, and Nature Positive).

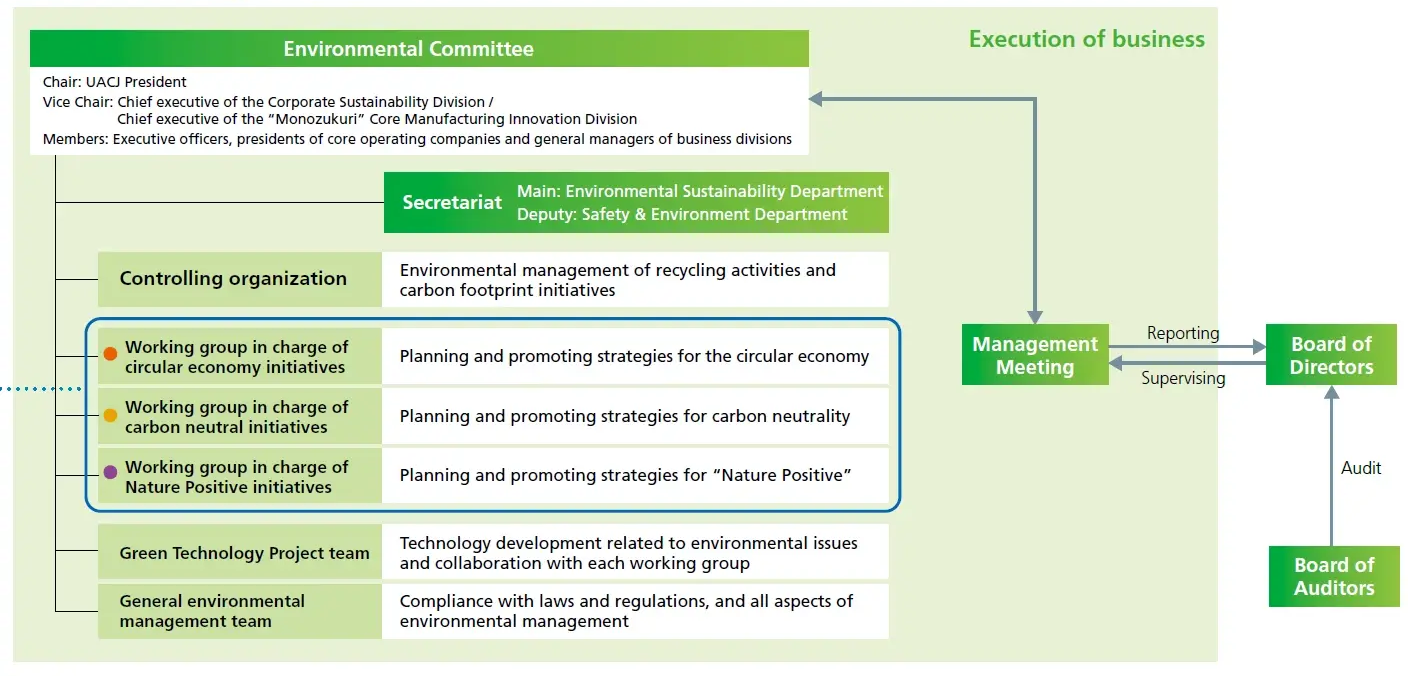

As our system for environmental initiatives, we have established an Environmental Committee chaired by the president. Under this committee, six working groups—a controlling organization, a carbon neutral WG, a circular economy WG, a Nature Positive WG, a Green Technology Project (GTPJ), and general environmental management—collaborate to advance initiatives. The results of WG deliberations and activities are reported from the Environmental Committee to the Board of Directors as necessary and receive approval.

Environmental management framework

Environmental Manager Meetings

Environmental managers from UACJ’s three manufacturing bases (located in Nagoya, Fukui and Fukuya), three works (two located in Nagoya and Oyama as well as the Foundry & Forging Works), the extrusion & metal components business, and foil business participate in Environmental Manager Meetings to confirm the Group’s progress toward its environmental targets and to exchange information on revisions to laws and regulations.

Environmental Management System

Environmental management systems are in place at each of the UACJ Group’s business locations, and nearly all of our plants have obtained the ISO14001 certification. Some of our smaller business locations have obtained the Eco-Action 21 certification by following the guidelines formulated by Japan’s Ministry of the Environment.

ISO14001:2015 Certifications (as of June 30, 2025)

| Business Location | Certifying Institution | Certification Number | Date Obtained |

|---|---|---|---|

| Nagoya Works | JIC Quality Assurance Ltd. (JICQA) | E440 | 2002.4 |

| Fukui Works | Det Norske Veritas (DNV) | 00484-2002-AE-KOB-RvA | 2002.4 |

| Fukaya Works | Japan Standards Association | JSAE545 | 2002.7 |

| Oyama Works | ASR | E2111 | 2002.9 |

| Nagoya Works(Extrusion Div.) | JIC Quality Assurance Ltd. (JICQA) | E440 | 2002.4 |

| UACJ Extrusion Anjo Corporation | JIC Quality Assurance Ltd. (JICQA) | E440 | 2002.4 |

| UACJ Extrusion Shiga Corporation | ASR | E2111 | 2002.9 |

| UACJ Extrusion Gunma Corporation | JIC Quality Assurance Ltd. (JICQA) | E773 | 2004.1 |

| UACJ Foil Corporation, Isesaki Works, Shiga Works, Nogi Works | JIC Quality Assurance Ltd. (JICQA) | E2442 | 2017.3 |

| Nikkin Co., Ltd. | JIC Quality Assurance Ltd. (JICQA) | E2442 | 2018.6 |

| Foundry & Forging Works | ASR | E2111 | 2002.9 |

| UACJ Metal Components Corporation, Ena Works | The High Pressure Gas Safety Institute of Japan | 04ER-420 | 2004.3 |

| UACJ Metal Components Corporation, Shiga Works | Japan Quality Assurance Organization | JQA-EM6018 | 2007.12 |

| UACJ Metal Components Corporation, Koriyama Works | JIC Quality Assurance Ltd. (JICQA) | E1711 | 2007.2 |

| Business Location | Certifying Institution | Certification Number | Date Obtained |

|---|---|---|---|

| UATH(Flat rolled products, Thailand) | JQA (JAPAN QUALITY ASSURANCE ORGANIZATION) | JQA-EM7557 | 2019.8 |

| UEXTH (Extrusion, Thailand) | UNITED REGISTRAR OF SYSTEMS | 57487/B/0001/UK/En | 2013.8 |

| UEXCZ (Extrusion, Czech Republic) | Lloyd's Register Group Limited | 10302172 | 2005.11 |

| UFOM (Foil, Malaysia) | AFNOR CERTIFICATION | N°2012/51248.3 | 2021.5 |

| UFFV(Foundry & forging, Vietnam) | SGS United Kingdom Ltd | VN14/00100 | 2014.8 |

| UMCM (Precision-machined metal components, Mexico) | BSI | EMS 572174 | 2012.12 |

| YJI (Precision-machined metal components, Indonesia) | BSI | EMS 557832 | 2010.1 |

| UMCTH (Precision-machined metal components, Thailand) | PERRY JOHNSON REGISTRARS,INC. | C2019-03001 | 2019.11 |

- Note Companies and sites as of September 30, 2025.

Eco-Action 21 (as of June 30, 2025)

| Business Location | Certifying Institution | Certification Number | Date Obtained |

|---|---|---|---|

| UACJ Metal Components Corporation, Narita Works | Chibaken Kankyo Zaidan | 341 | 2005.5 |

| UACJ Aluminum Center Corporation, Utsunomiya Color Aluminum Works | Institute for Promoting Sustainable Societies | 12021 | 2017.10 |

| UACJ Metal Components Corporation, Hiroshima Works | Institute for Promoting Sustainable Societies | 12626 | 2018.12 |

| UACJ Metal Components Corporation, Sendai Works | UACJ Metal Components Corporation, Sendai Works | 12744 | 2019.4 |

- Note Companies and sites as of September 30, 2025.

Initiatives

On-site Inspections

On-site inspections are conducted at Group business sites in Japan to prevent environmental troubles, formulate and promote execution of measures to reduce and eliminate risks, and to ensure full compliance with environmental laws and regulations.

Inspection teams consisting of environmental officers and members of the Safety & Environment Department visit the business sites and utilize a site’s environmental reports and on-site verification to inspect the status of compliance with laws and regulations and the progress of improvement measures. The Safety & Environment Department provides guidance and support for issues that need to be addressed. The inspections are part of our efforts to raise the Group’s level of environmental management.

Status of Compliance with Environmental Laws and Regulations

In fiscal 2024, one accident occurred in which wastewater slightly exceeded the regulatory environmental standard. On September 30, 2024, a regular on-site inspection by Kusatsu City was conducted at UACJ Foil Corporation's Shiga Works. At that time, the mass of n-hexane extracts in the sampled sewer (domestic) wastewater slightly exceeded the standard value. We reported that the main cause was a reduction in wastewater volume due to water-saving measures, which concentrated oil components derived from hand-washing detergent. As recurrence prevention measures, we are implementing detergent improvement, wastewater volume management, and establishment of an inspection system.

Environmental Investment

The UACJ Group’s environment-related investment in fiscal 2024 amounted to approximately ¥320 million. Investments included replacement of DX gas generators (Nagoya Works), renewal of rolling mill coolant piping (Fukui Works), renewal of air-conditioning equipment (all sites), renewal of PCB-containing electrical equipment (all sites), and conversion of ceiling lighting to LED (all sites).

Environmental Education

We conduct environmental education for all employees as another measure for fulfilling our social responsibility to protect the global environment.

The Safety & Environment Department and the environment units of individual business locations lead environmental education initiatives. The Safety & Environment Department conducts fundamental environmental education activities, the purposes of which are to enlighten and raise awareness of environmental protection, and promote understanding of the UACJ Group’s Basic Environmental Policies. Meanwhile, the environment units of individual business locations carry out environmental education initiatives to foster the skills and numbers of internal auditors needed to ensure that each business location conducts its daily activities with sensitivity toward the environment.

We encourage employees to obtain public qualifications in environmental fields and are developing a workforce that is capable of appropriately responding to trends in environmental regulation. Individual business locations conduct general environmental education programs and special education programs for employees engaged in work that could have significant environmental impacts.

Numbers of Employees with Environmental Management Qualifications (As of April 30, 2025)

| Qualification | Qualified Employees |

|---|---|

| Pollution Control Manager - Air | 52 |

| Pollution Control Manager - Water | 43 |

| Pollution Control Manager - Noise | 14 |

| Pollution Control Manager - Vibration | 10 |

| Pollution Control Manager - Noise & Vibration | 16 |

| Pollution Control Manager - Dioxins | 24 |

| Energy Manager | 53 |

| Certified Environmental Measurer | 2 |

| Manager Responsible for Industrial Waste Requiring Special Controls | 56 |

| Manager Responsible for Handling of Poisons and Deleterious Substances | 12 |

| ISO14001 Internal Auditor | 237 |

- Data is for all UACJ and Group companies in Japan.