UACJ's Vision for Building an Aluminum Circular Society

- HOME

- Sustainability

- A Future where the Earth can Continue to be Beautiful and Bountiful

- UACJ's Vision for Building an Aluminum Circular Society

Our Approach

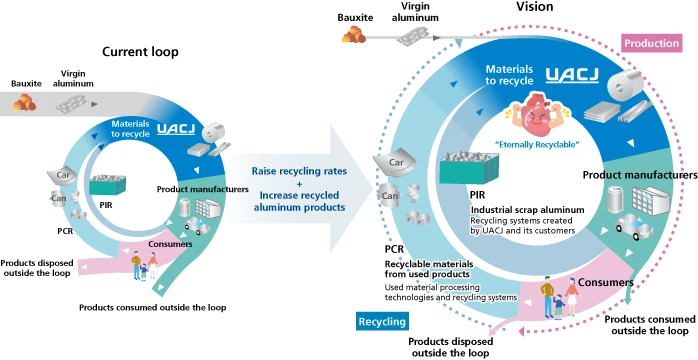

Aluminum is a material that can freely change shape and be reborn any number of times. We at UACJ fulfill the role of the "heart" that drives the circulation of aluminum recycling by connecting the material’s arteries (supply to society through customers in the manufacturing sector) and veins (return of recycled raw materials derived from various types of scrap).

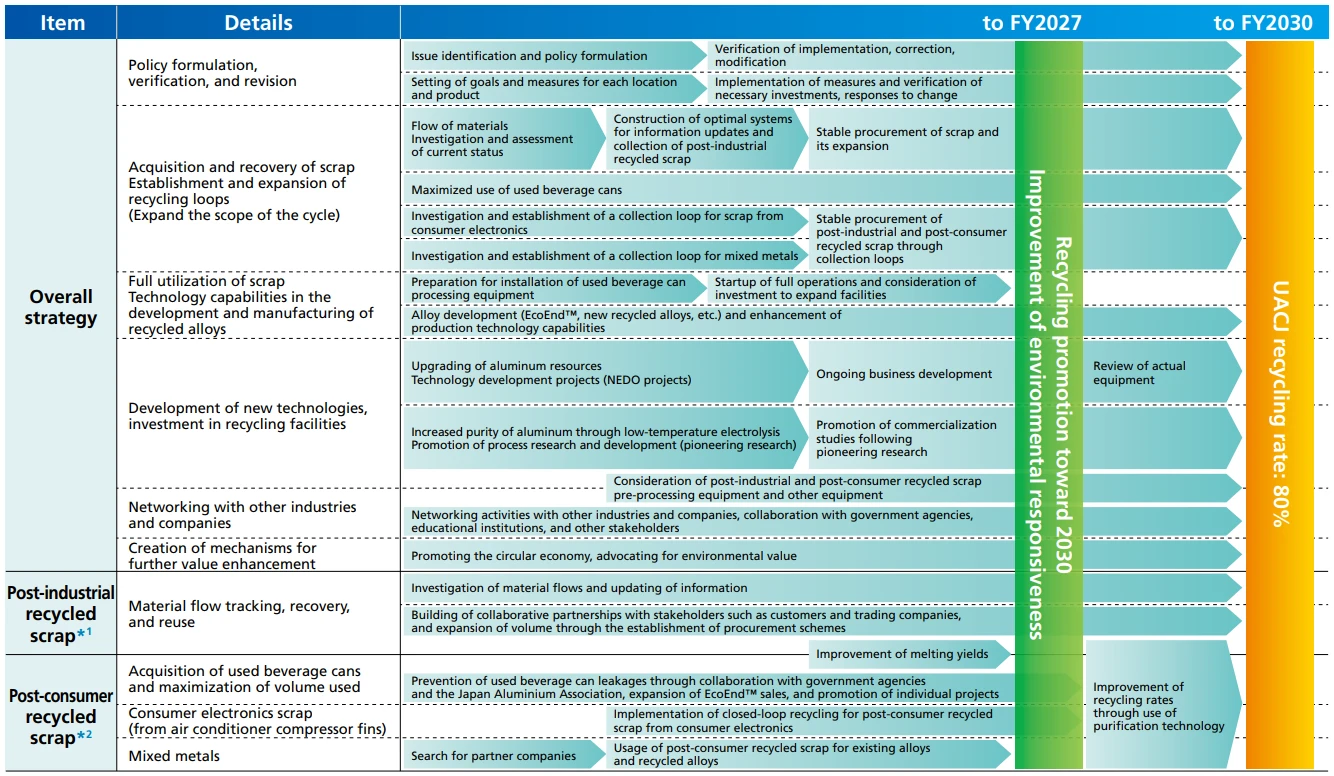

The promotion of a circular economy through aluminum recycling not only helps to create a recycling-based society, but also contributes to climate change countermeasures and Nature Positive initiatives. To this end, we have formulated and are implementing a road map to serve as the “heart” that promotes the recycling of aluminum, connecting the “arteries” that turn aluminum materials into products and deliver them to society with the “veins” that collect used products and scrap materials and return them to society again as recycled products.

Regarding the stable procurement of PIR*1 scrap, we will continue to establish schemes for can materials, automotive materials, home appliances, etc., and promote the recycling of materials used in the aerospace and defense industries, etc. Meanwhile, for PCR*2 scrap, we will establish a recycling system for automobiles, home appliances, and similar items. In addition, we will be involved in NEDO*3 projects and will be developing the technologies needed to establish a recycling loop.

In addition to these road maps, in order to drive the development of a recycling-based society for aluminum, we have also set a target of achieving a UACJ recycling rate*4 of 80% by fiscal 2030.

We will continue to explore the possibilities of aluminum to “lead a circular economy in aluminum” and realize “a future where the Earth can continue to be beautiful and bountiful.”

- Post-Industrial Recycled: Scrap generated during the processing of materials in the manufacturing industry

- Post-Consumer Recycled: Scrap derived from used products

- New Energy and Industrial Technology Development Organization

- A UACJ indicator that measures the recyclability of aluminum, calculated as the ratio of recycled aluminum to the amount charged to the melting furnace

Road map for leading a circular economy in aluminum

Recirculating systems created with aluminum

Aluminum Recycling: Our 3 Initiatives

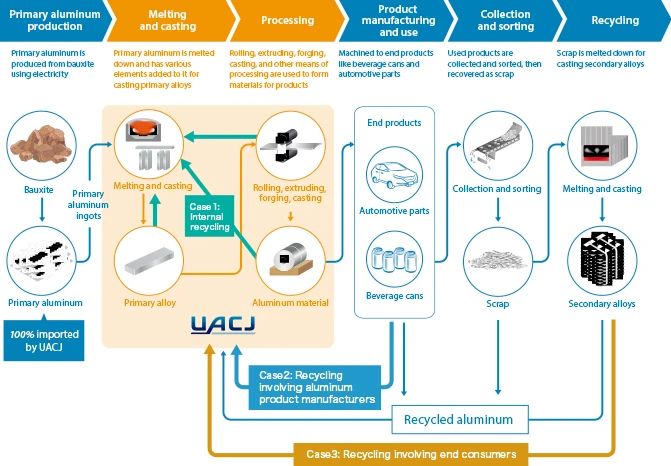

UACJ uses the technology it has developed over many years to make the best use of scrap generated in the material production process at its own plant, as well as scrap from the machining process at users of aluminum materials, and materials recovered from used products. Below are three specific examples of our efforts.

- Case 1: Internal recycling

Use of scrap generated in the material production process at our own plant - Case 2: Recycling involving aluminum product manufacturers

Use of scrap from machining process at large consumers - Case 3: Recycling involving end consumers

Use of materials recovered from used products

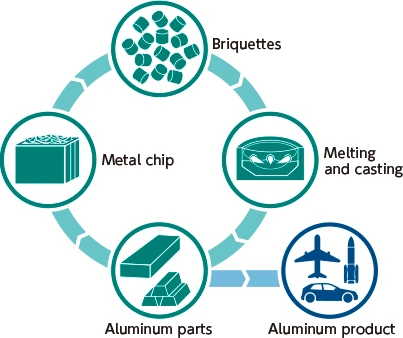

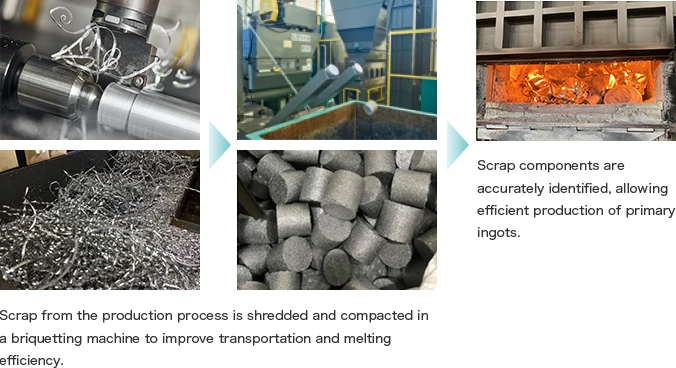

Case 1: Internal recycling:Promote recycling by introducing briquetting machines

Scrap generated in the material production process in the company's own plant is collected. After being compressed by a briquetting machine (metal chip compressor), it is melted down in the same way as primary aluminum and various elements are added. This allows the primary alloy to be cast again.

At each of UACJ's production site, scrap is considered a valuable resource and is reused to the maximum extent possible.

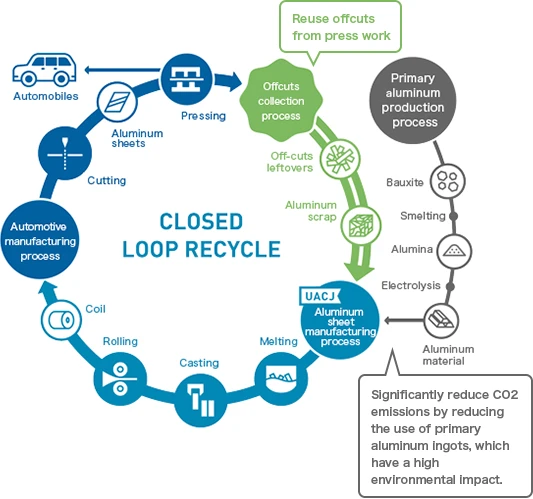

Case 2: Recycling involving aluminum product manufacturers:Reuse of scrap from automakers

Aluminum is easy to process and lightweight. Its use in automotive bodies can reduce fuel and energy consumption.

UACJ contributes to the reduction of environmental impact by collecting and reusing scrap from the automotive manufacturing process (this process is called "closed loop recycling").

Case 3: Recycling involving end consumers:Promote recycling of aluminum cans

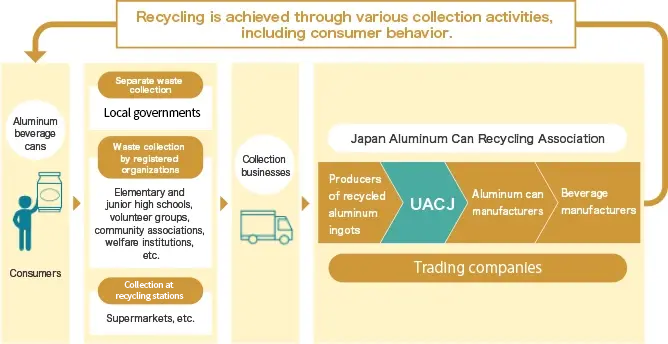

The recycling rate of aluminum beverage cans in Japan is one of the highest in the world at over 95%. As a member of the Japan Aluminum Can Recycling Association, UACJ Group actively participates in aluminum beverage can recycling activities.

In addition UACJ is promoting unique recycling initiatives such as “Can to Can recycling” (purchasing collected used aluminum cans as raw materials for recycling at each production site) and developing "EcoEnd(TM)" low-carbon aluminum beverage can lids with Toyo Seikan Group Holdings, Ltd.

- Percentage of used beverage cans recycled domestically and exported out of all aluminum cans consumed domestically.

(Used beverage cans recycled domestically + exported) / all aluminum cans consumed domestically