Occupational Safety and Health

- HOME

- Sustainability

- A Healthy and Harmonious Society where Everyone can Feel Well-being

- Occupational Safety and Health

Basic Policy and Management Structure

Basic Approach Occupational Safety and Health

In the belief that “the health and safety of our employees takes precedence over everything,” UACJ is working to create safe, hygienic, and healthy work environments by complying with labor-related laws and internal regulations, establishing an occupational health and safety management system, and conducting appropriate management. Occupational health and safety was listed as one of the materiality issues we identified in fiscal 2021, but in recognition of the fact that “ safe workplaces should be pursued as a matter of course,” we decided in fiscal 2023 to position it as one of our “Shared Foundation” — that is, something to be considered a natural state of affairs at UACJ.

Basic Policies on Safety and Health

Philosophy

The UACJ Group, recognizing that the existence of a business enterprise rests on a foundation of employee safety and health and that ensuring employee safety and health is a social responsibility of business enterprises, will respect the following principles as a matter of course.

Action Guidelines

- We will place employee safety and health before all else in all business activities.

- To eliminate all workplace hazards as a step toward achieving zero workplace accidents, we will take the required organizational measures, allocate the necessary management resources, and, with the participation of all employees, strive to implement safety and health activities on an ongoing basis.

- We will comply with the Industrial Safety and Health Law and other related laws and ordinances, and ensure employee safety and health in accordance with the safety and health provisions established by the Group companies.

- Gaining the cooperation of employees, we will conduct education and training that is necessary and adequate for ensuring safety and health for all employees, and continuously implement safety and health activities, to constantly elevate safety and hygiene standards.

- Sharing information on safety and health activities within the Group, and pursuing mutual enlightenment, we will work to improve understanding of safety and health principles, and raise safety and health awareness, among all employees.

- We will advance the development of comfortable work environments to reduce worker fatigue and stress.

- We will work to develop and implement new safety and health methods and technologies.

Safety and Health Management System

Safety and Hygiene Committee

In the January 2025 meeting of the Safety and Hygiene Committee, a report on fiscal 2024 activities was presented by the Safety & Environment Department and then the committee deliberated and approved the directions to be taken for fiscal 2025 safety and hygiene activities.

Business locations that achieved accident-free operations in fiscal 2024 were presented with President’s Safety Awards.

- [Presentations of President’s Safety Awards (12 business locations)]

Foundry & Forging works, UACJ Thailand Co., Ltd.(Rayong), UACJ Extrusion Shiga Corporation, UACJ Extrusion (Thailand) Co., Ltd.、UACJ Extrusion Czech s.r.o.、UACJ Metal Components Corporation(Narita)、UACJ Metal Components Central Mexico, S.A. de C.V.、UACJ Foil Corporation(Isesaki), UACJ Foil Malaysia Sdn. Bhd.、UACJ Aluminum Center Corporaion(Utsunomiya Color Aluminum, Nara), Nikkin Co(Saitama) - Companies and sites as of September 30, 2024

Safety and Hygiene Managers’ Committee

The Safety and Hygiene Managers’ Committee, with members including representatives of the Safety & Environment Department, and Safety Managers of the works and principal affiliates, meets once every month to discuss safety and work environment inspections and maintenance at each business location. The committee also refines the unified rules and promotes their inculcation across the breadth of the Group.

Going forward, we will continue to act vigorously to ensure that our safety and health management systems are equal to our needs.

Safety Management Initiative

Occupational Safety and Health Management System

The Nagoya, Fukui, and Fukaya works have adopted and are operating worker safety and health management systems, and are pursuing activities with the goal of achieving zero accidents in the workplace.

Safety and health activity plans are prepared at each works in accordance with the UACJ Group’s safety and health activity aims. Plans are finalized once they are approved by the head of each works, and then discussed and approved by the worker/management joint Safety and Health Committee at each works.

To help ensure that safety and health management is practiced at the highest standards, we have established internal audit and other schemes based on the management system. Through internal audits, we conduct self-assessments of system operations, assuring in the process, that PDCA (Plan-Do-Check-Action) cycles are being used. In addition, to enhance the safety management standards of the entire Group, we hold annual liaison meetings of people in charge of safety and hygiene at Group companies.

To achieve further enhancement going forward, we intend to improve the accuracy of internal audits.

Conditions with Regard to Workplace Accidents

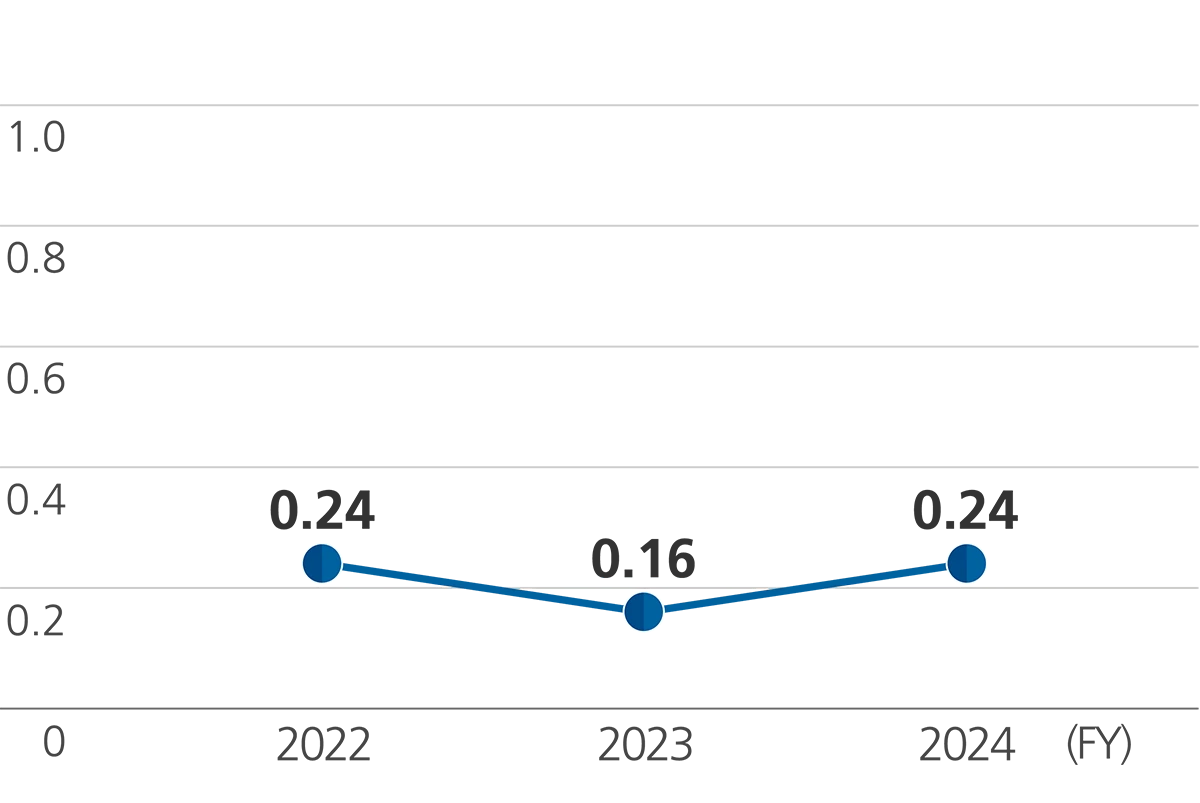

In the most recent three year period, the number of workplace accidents*1 at Group companies in 2022 was 6, in 2023 was 4, and in 2024 was 6. The overall frequency in 2024*2 was 0.24.

- Indicators were revised in fiscal 2022 to increase their effectiveness.

UACJ Group Frequency Rate of Workplace Accidents*2

- Number of accidents is the total number of accidents resulting in death, lost worktime, and or non-lost worktime.

Scope: UACJ Group business sites, including overseas business sites (including on-site subcontractors) - Overall frequency serves as an index for evaluating the occurrence (frequency) of occupational accidents by multiplying the number of accidents (including non-lost worktime) due to occupational accidents by one million and dividing by the number of total working hours during the statistical period.

Toward Intrinsic Safety

The UACJ Group is striving to achieve intrinsic safety in its equipment and facilities. To do this, we are conducting risk assessments by examining work processes from various angles to thoroughly eliminate hazards and harmful factors. Safety measures are taken beginning with the facilities, equipment, and work approaches evaluated as having high risk levels. Residual risks, too, are all addressed with provisional measures.

Based on uniform equipment safety standards the group introduced in March 2015, zones are being delineated within facilities and thorough safety measures are being implemented for each. Furthermore, when facilities are to be newly introduced or modified, intrinsic safety is achieved by conducting checklist-based safety examinations at the design, operation startup, and other stages.

Safety-First Corporate Culture and Personnel Development

At the UACJ Group, job-level training includes safety and health education, and content aimed at raising safety awareness. Furthermore, experiential training aimed at enhancing awareness of dangerous situations, and competitions to encourage workers to hone crane and forklift skills, are held regularly.

For managers, safety and health education and training sessions are held to promote acquisition of the position, knowledge, and attitudes necessary for implementing safety management. In addition, to elevate safety and health management standards at individual Group companies, safety and health education, safety inspections, and other support initiatives are actively undertaken to foster a safety-first corporate culture and advance personnel development along the same lines throughout the Group.

Principal Safety and Health Awards

| Award | Recipient | |

|---|---|---|

| 2024 Japan Aluminum Association Workplace Safety Award of Excellence |

Special Award of Excellence | UACJ Extrusion Gunma Corporation UACJ Extrusion Anjo Corporation UACJ Foil Corporation(Isesaki) UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum) |

Workplace Environment Improvement Activities

To make better workplace environments, we are systematically taking steps to improve conditions with regard to summer heat, winter cold, dust, and noise; eliminate work that requires excessive physical exertion or taxing body positions; and add break areas and other features (e.g. adding or renovating break areas and on-site restrooms) that make environments more livable. Concerning summer heat in particular, we are moving forward with installation of air conditioning and ventilation equipment in places where it is needed and introducing clothing with integrated fans.