Production and manufacturing fields of UACJ

- HOME

- Technology and R&D

- Equipment and Production Technology

- Production and manufacturing fields of UACJ

Deploying world-leading manufacturing capabilities with sophisticated facilities and long-cultivated technology

UACJ, a world-class aluminum manufacturer. Our competitiveness comes from craftsmanship and manufacturing capabilities supported by a diverse range of advanced production facilities. Leveraging one of the industry’s largest facilities for hot and cold rolling, extrusion, casting, and forging, we manufacture large products not matched by others and achieve high productivity.

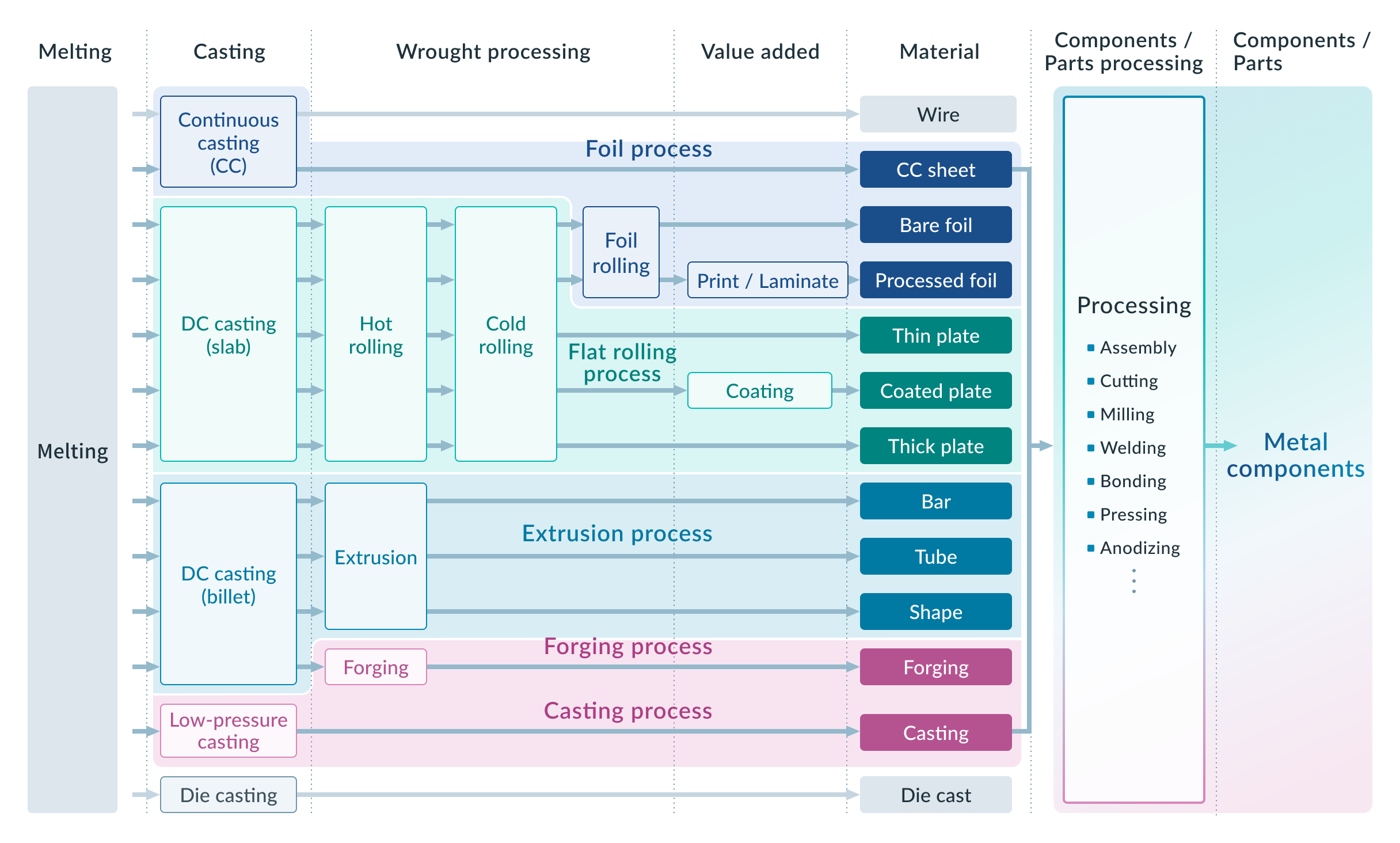

Harnessing our capabilities in casting, rolling (thin sheet, thick sheet, foil), extrusion (tubes, bars, shapes), forging, machining, and more, we have established a global supply system including sheet production bases in Japan, the US, and Thailand.

- CC:Continuous Casting DCCasting:Direct Chill Casting

Casting technology

UACJ uses direct chill (DC) casting, which makes it possible to achieve high quality efficiently. By solidifying molten metal rapidly, high-quality slabs and ingots with few internal defects are produced and demonstrate excellent performance in sheet rolling and extrusion. We also use low-pressure casting, which achieves uniformity and high dimensional precision, enabling us to provide high-strength castings in complex shapes.

Sheet and foil rolling technology

Plate is produced by flat rolling—a processing method in pair of parallel rollers is rotated to turn an aluminum ingot, called a slab, into a thinner product, a plate.

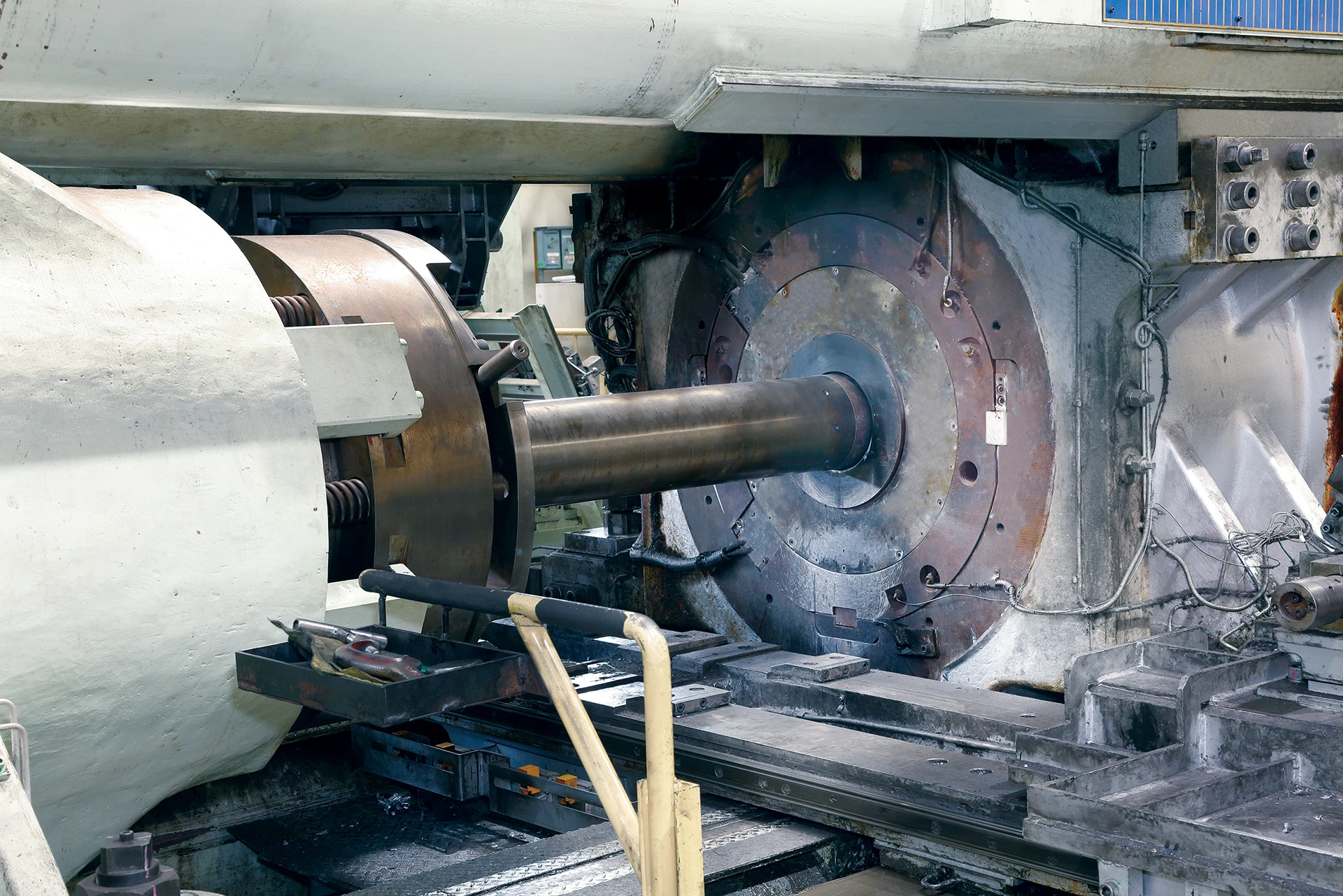

Extrusion technology

Extrusion is used to manufacture products that have different cross sections. Aluminum ingots, called billets, are extruded at high pressure and temperatures of 350°C to 550°C through dies of different shapes to manufacture products.

Forging technology

UACJ pioneered the manufacture of forged aluminum products in Japan and has been growing with and contributing to the development of aviation and space technologies. The use of high-strength, reliable, large forged aluminum products is not limited to aircraft and rockets, but is expanding to high-speed railways, semiconductor manufacturing equipment, and ships.

Processing technology

Aluminum products are used for a wide variety of applications, from transport vehicles such as automobiles and aircraft to the construction industry. They also come in many different shapes and sizes. These products are created by diverse processing techniques. We perform a wide range of processing such as cutting, milling, forming (e.g., bending and drawing), joining of dissimilar materials or various shapes of members, and surface treatment including coating, coloring, and anodizing. We provide one-stop solutions from the design stage to meet customer needs.

Recycling technology

Pursuing a sustainable future in coexistence with the planet and aiming to contribute to a circular economy, we are striving to develop advanced sorting and recycling technologies for removing elemental impurities.