Environmental Consideration in Products

Basic Approach

The UACJ Group is working to enhance the functionality of aluminum materials to realize a low-carbon and recycling-oriented society.

Aluminum products can play a central role in a circular economy and in addressing global environmental issues. Our ALmitas⁺ SMART and other aluminum products reduce environmental impact, and we make maximum use of aluminum scrap and other post-consumer recycled materials.

| Product Development and Improvement | Contributions that Benefit the Environment and Society |

|---|---|

| Promote development and practical application of highly recyclable can stock materials | Advance horizontal recycling for resource circulation and greenhouse gas (GHG) reduction |

| Advance development and practical application of thermal management products using cast pin fins and extruded pipes | Save resources and reduce GHG emissions by improving thermal exchange performance to enable smaller and lighter equipment |

| Develop and improve aluminum materials to use as exterior panels, structural members, and batteries (housing, casing, battery foil) in next-generation automobiles | Reduce vehicle weights to save resources, improve fuel efficiency, and lower GHG emissions |

| Create an ALmitas⁺ SMART mass balance system to provide low GHG products | Provide low GHG products to reduce environmental impact Increase the volume of raw material recycling to promote resource recycling |

UACJ products represent roughly half of all the materials used in aluminum cans manufactured in Japan, which in fiscal 2022 amounted to approximately 330,000 tons of material for 21.5 billion cans. As part of our responsibility as the leading manufacturer of aluminum products, we actively promote the recycling of aluminum can scraps.

We are also simplifying and streamlining the delivery packaging of products and other items and streamlining our logistics processes for collecting and reusing packaging materials and racks.

Control of Chemical Substances included in Products

The UACJ Group strictly enforces proper controls over chemical substances used in its products. We respond to changes in environmental laws in Japan (such as to the Industrial Safety and Health Act and Chemical Substances Control Law) and overseas environmental laws (such as the EU REACH*1 regulation) by verifying the changes and making the necessary changes.

*1 REACH regulation: Registration, Evaluation, Authorization and Restriction of Chemicals.

Understanding and Communicating Information on Chemical Substances in Products

The UACJ management system ensures that we can fully communicate to our customers information from raw material manufacturers on the chemical substances contained in our products.

The Quality Assurance Department and the Environmental Management Department work together to provide chemical substance information in common industry formats in response to customer requests.

[Examples of Information Provision Formats]

- Safety Data Sheet (SDS) *2

- IMDS *3

- chemSHERPA *4

- *2 Safety Data Sheet (SDS): Documents with information on product hazards and other data and information in compliance with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS)

- *3 International Material Data System (IMDS): The material data system used in the automobile industry

- *4 Chemical information SHaring and Exchange under Reporting PArtnership (chemSHERPA): A system for communicating product chemical substance throughout the supply chain

Environmental Quality Management System Certifications by Customers

At its business locations required to have specified supplier certifications, the UACJ Group emphasizes the practice of chemical substance management that satisfies customer standards, and undergoes environmental quality management system certifications by customers. Going forward, we will continue to practice management that enables proper responses to customer demands.

Creating a system to reduce environmental impact

Closed-loop recycling

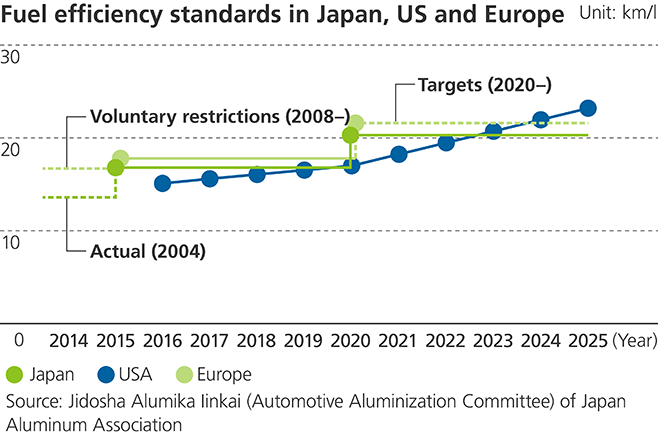

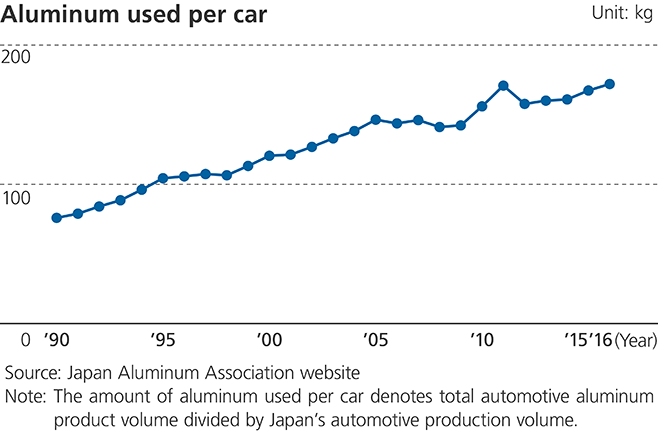

Aluminum is about one-third the weight of steel while offering high strength, corrosion resistance, and recyclability. Aluminum content in vehicles is expected to continue growing by roughly 3% annually in North America and likewise is increasing worldwide. Use is expected to also grow for electric vehicles and other types of transportation.

The UACJ Group is also contributing to closed-loop recycling of automobiles.

A closed-loop recycling is a system to collect industrial scrap materials and our own post-consumer products and reusing them multiple times while maintaining the quality of the original materials.

Approximately 90% of the CO2 emissions from aluminum manufacturing processes is generated in the smelting process of new aluminum ingots. In addition, reusing scrap material from press processes produces significantly less CO2 emissions than in the smelting and refining process for new aluminum ingots. Our closed-loop recycling system collects and reuses all scrap material from the vehicle manufacturing process, resulting in less use of new aluminum ingots and lower CO2 emissions.

Presenting the mass balance method option for reducing environmental impact

Japan is experiencing the effects of climate change with increasing incidents of extremely hot days and natural disasters, and companies and organization are being pressed to take urgent action. Some estimates show that CO2 emissions, a chief cause of global warming, are some 60% higher than they were 30 years ago. United Nations member countries responded in December 2015 by adopting the Paris Agreement at the 21st Conference of the Parties (COP21) to the United Nations Framework Convention on Climate Change (UNFCCC) in Paris. The Paris Agreement includes decarbonization with the goal of reducing GHG emissions to net zero in the second half of the 21st century.

In October 2020, the Japanese government declared its aim to achieve a decarbonized society with net zero GHG emissions by 2050.

UACJ followed in 2021 with the introduction of the new eco-friendly product brand, ALmitas⁺ SMART.

We expanded the options for customers seeking to improve their environmental performance by introducing the ALmitas⁺ SMART Mass Balance in April 2023. The system uses a third-party verified mass balance system for managing new aluminum ingot manufactured using green energy and closed loop recyclable materials and for ensuring controlled GHG emission intensity.

ALmitas⁺

ALmitas is an aluminum material and product brand that conveys the ever-expanding possibilities and appeal of aluminum, co-created with various partners using the UACJ Group’s proprietary technologies cultivated over the years. Based on our corporate philosophy of “Contribute to a prosperous and sustainable society with technologies that bring out the innate power of Materials,” we will continue to pursue the value of aluminum through the development of this brand, while communicating this value to the world and aiming to solve social issues through the business.

- Note 1 Mass balance: One of the management methods defined in the GHG Protocol and ISO 22095 for managing a mixture of raw materials and products with various origins and properties. It is also being introduced in other materials industries.

- Note 2 GHG (Greenhouse Gas): Includes gases other than CO2 such as methane, nitrous oxide, and hydrofluorocarbons. The refining process to obtain new aluminum ore involves the emission of gases other than CO2. Therefore, the International Aluminum Institute (IAI) and other organizations disclose GHG emissions.

- Note 3 Cradle to Gate: A term used in life cycle assessment (LCA) to refer to the entire process from mining of raw materials to product shipment.

- Note 4 The appropriateness of operations has been verified (limited assurance) by a third-party organization (JICQA).