Fighting Global Warming

Basic Approach

The UACJ Group considers energy conservation to prevent global warming as a priority management issue. The director and executive officer serves as the chief executive officer in charge of energy management. Each year, action goals are set for reducing per-unit energy consumption from the previous fiscal year, and we pursue a policy of steadily implementing every measure possible to achieve the goals. Our medium-to-long-term objective is to improve our energy consumption per unit of production by an average of at least 1% annually, which is the target presented in the Energy Efficiency Act*1. The Environmental Committee (formerly the Climate Change Countermeasure Steering Committee) is charged with promoting these initiatives.

*1 Energy Conservation Act: Act on the Rationalization of Energy Use and Conversion to Non-Fossil Energy

Fiscal 2023 Results

The UACJ Group consumed a total of 17.2 million GJ of energy in fiscal 2023, a decrease of 13.1% from fiscal 2022.

Group CO2 emissions were 467,000 t-CO2 for Scope 1 and 366,000 t-CO2 for Scope 2 (reference value: market standard), for a total of 833,000 t-CO2, approximately 175,000 t-CO2 less than in fiscal 2022.

Group CO2 emissions per unit production were 0.917t-CO2/product ton, an 8.1% decrease from fiscal 2022.

Location-based method Scope 2 emissions were 446,000 t-CO2.

The improvement in the basic units is primarily attributable to ongoing improvement measures and the purchase of 240 million kWh of renewable energy electricity, which more than offset the deterioration in emission intensity accompany the lower production volume in fiscal 2023.

UACJ Group CO2 Emissions (Japan + overseas)

| Fiscal 2019 | Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | Fiscal 2023 | ||

|---|---|---|---|---|---|---|

| Fuel Scope 1 CO2 emissions (thousand tons CO2) |

ー | 514 | 493 | 557 | 528 | 467 |

| Electricity Scope 2 CO2 emissions (thousand tons CO2) |

Location-based | 492 | 446 | 479 | 480 | 446 |

| reference value: market standard*2 |

ー | ー | ー | ー | 366 | |

| Scope 1+2 CO2 emissions (thousand tons CO2) |

Location-based | 1,005 | 939 | 1,037 | 1,008 | 913 |

| reference value: market standard*2 |

ー | ー | ー | ー | 833 | |

| CO2 emissions per product ton*1 (t-CO2/product ton) |

Location-based | 1.118 | 1.109 | 0.999 | 0.998 | 1.001 |

| reference value: market standard*2 |

ー | ー | ー | ー | 0.917 |

- Note 1 Companies and sites as of September 30, 2024

- Note 2 Measurement scope:

(Japan) UACJ (Nagoya, Fukui, Fukaya), UACJ Extrusion Nagoya Corporation (Nagoya, Anjo), UACJ Extrusion Oyama Corporation, UACJ Extrusion Shiga Corporation, UACJ Extrusion Gunma Corporation, UACJ Foil Corporation (Shiga, Nogi, Isesaki), Nikkin Co., Ltd. (Saitama), UACJ Foundry & Forging Corporation, UACJ Metal Components Corporation (Sendai, Narita, Ena, Shiga, Hiroshima, Koriyama), UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum, Fukaya, Shiga, Nara), Izumi Metal Corporation, Kamakura Industry Co., Ltd., UACJ Marketing & Processing

(Overseas) UACJ (Thailand) Co., Ltd., UACJ Extrusion Czech s.r.o., UACJ Extrusion (Thailand) Co., Ltd., UACJ Foundry & Forging (Vietnam) Co., Ltd., UACJ Foil Malaysia Sdn. Bhd., UACJ Automotive Whitehall Industries, Inc.(6th Street、Madison、Progress Drive、Paducah、Flagstaff、Mexico), UACJ Metal Components Mexico, S.A. de C.V., UACJ Metal Components Central Mexico, S.A. de C.V., UACJ Metal Components (Thailand) Co., Ltd, P.T. Yan Jin Indonesia - *1 Measurement scope:

(Japan) UACJ (Nagoya, Fukui, Fukaya), UACJ Extrusion Nagoya Corporation (Nagoya, Anjo), UACJ Extrusion Oyama Corporation, UACJ Extrusion Shiga Corporation, UACJ Extrusion Gunma Corporation, UACJ Foil Corporation (Shiga, Nogi, Isesaki), UACJ Foundry & Forging Corporation, UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum)

(Overseas) UACJ (Thailand) Co., Ltd., UACJ Extrusion Czech s.r.o., UACJ Extrusion (Thailand) Co., Ltd., UACJ Foundry & Forging (Vietnam) Co., Ltd., UACJ Foil Malaysia Sdn. Bhd., UACJ Automotive Whitehall Industries, Inc.(6th Street、Madison、Progress Drive、Paducah、Flagstaff、Mexico) - *2 Country emission factors are used for overseas business units when power company emission factors are not available.

UACJ CO2 Emissions (Parent only)

| Fiscal 2021 | Fiscal 2022 | Fiscal 2023 | ||

|---|---|---|---|---|

| Fuel Scope 1 CO2 emissions (t-CO2/yr.) |

ー | 363 | 338 | 309 |

| Electricity Scope 2 CO2 emissions (t-CO2/yr.) Location-based |

Location-based | 243 | 234 | 228 |

| reference value: market standard |

ー | ー | 195 | |

| Scope 1+2 CO2 emissions (t-CO2/yr.) |

Location-based | 606 | 571 | 537 |

| reference value: market standard |

ー | ー | 504 | |

| CO2 emissions per product ton (t-CO2/product ton) |

Location-based | 1,041 | 0.969 | 0.967 |

| reference value: market standard |

ー | ー | 0.91 |

Fiscal 2023 UACJ Group CO2 Emissions (Scope 3 Japan + overseas)

| Components | CO2 Emissions (kt-CO2) |

|---|---|

| Category 1: Purchased goods and services | 4,524 |

| Category 2: Capital goods | 116 |

| Category 3: Fuel- and energy-related activities not included in scopes 1 and 2 | 143 |

| Category 4: Upstream transportation and distribution | 106 |

| Category 5: Waste generated by business operations | 0.4 |

| Category 6: Business trips | 1 |

| Category 7: Employee commuting | 2 |

| Category 12: End-of-life treatment of sold products | 0.1 |

| Total | 4,893 |

Categories 8-11, 13-15 were excluded from the calculation because of their miniscule impact.

Main Initiatives in Production Processes

New Energy Saving Subcommittee

The UACJ Group Energy Saving Subcommittee meets regularly to promote energy-saving activities at business sites. Beginning in FY2022, we created the New Energy Saving Subcommittee with a revised member makeup and meeting schedule with the aim of stepping up our activities to reduce GHG emissions and promote energy conservation.

Examples of Energy-Saving Activities

The table below shows the main energy-saving activities implemented by the UACJ Group in fiscal 2023.

Group business sites are also implementing energy-saving measures, which include changing furnace heating systems, updating electrical equipment, and repairing steam and air leaks.

Examples of CO2 Emissions Reductions (New for fiscal 2023)

| Business Location | Theme | CO2Emissions Reduction Impact (t-CO2/yr.) |

|---|---|---|

| Nagoya Works | Improvement of heating furnace re-ignition after misfires | 800 |

| Multiple business sites | Improvement of heating furnace re-ignition after misfires | 400 |

| Nagoya Works | Improvement of melting furnace damper control during re-ignition | 300 |

| Nagoya Works | Upgrading to low-pressure (reverse osmosis) RO membranes | 200 |

Switching to LNG as a Heat Source for Production Processes

Using LNG as a heat source produces approximately 30% less CO2 emissions compared to LNG and heavy oil with the same calorific value.

As of the end of fiscal 2023, LNG (including city gas) accounted for approximately 90% of the fuel used at our three works on a calorific value basis.

Introduction of renewable energy-derived electricity

The UACJ Group is systematically introducing renewable energy-derived electricity to power its business sites. In fiscal 2023, we purchased approximately 240,000 kWh of renewable energy-derived electricity both in Japan and overseas through on-site PPAs, renewable energy electricity options, and non-fossil fuel certificates. This will reduce our CO2 emissions by approximately 105,000 t-CO2 per year*3. Of particular note, 20 domestic business sites*4 have switched to 100% renewable energy-derived electricity.

- *3 The CO2 emission coefficient was calculated using the national average for fiscal 2022, which is 0.438 kg-CO2/kWh.

- *4 UACJ Extrusion Nagoya Corporation (Anjo), UACJ Extrusion Gunma Corporation, UACJ Extrusion Shiga Corporation, UACJ Foundry & Forging Corporation, UACJ Metal Components Corporation (Sendai, Narita, Ena, Shiga, Hiroshima, Koriyama), UACJ Aluminum Center Corporation (Utsunomiya Color Aluminum, Shiga, Nara),UMP, Kamakura Industry Co., Ltd., Izumi Metal Corporation (Yamagata Logistics Center, Tochigi Logistics Center, Noda Logistics Center, Kawasaki Logistics Center, and Yashio Logistics Center)

- Note Companies and sites as of September 30, 2024.

Main Initiatives in Logistics

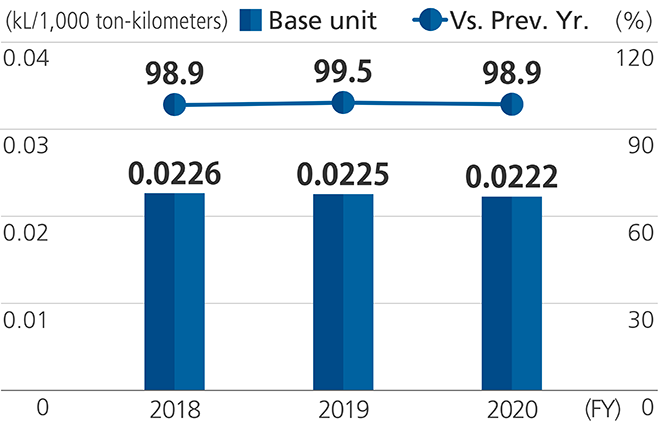

UACJ is taking steps to reduce the energy it uses in its logistics processes. As a “specified consignor”*5 as defined by the Energy Efficiency Act *6, UACJ is promoting activities with the aim of improving transport energy efficiency per ton-kilometer by an average of 1% annually over five years.

Transport energy intensity per sales volume in fiscal 2023 improved by 1.7% compared to fiscal 2022. This was driven by the increased effectiveness of improvement activities, such as those to increase load factor and boost the volume of ship transport.

Additionally, since 2001, we have worked closely with other companies in the same industry in an effort to reduce CO2 emissions for some of our aluminum extrusion products by using joint logistics to improve transport efficiency.

- *5 A specified consignor is a shipper that annually transports more than 30 million ton-kilometers of their own cargo

- *6 Energy Efficiency Act: Also known as the Act on the Rational Use of Energy, the act calls for consignor companies, which place orders with freight transport firms, and others to form specific plans to conserve energy and to reduce energy consumption.

Amount of Energy Used for Shipping, per Unit of Sales

- * Periodic report submitted values

Main Initiatives in Offices

Energy-Saving Activities in Offices

UACJ takes active steps to reduce energy consumption in its offices, including by controlling temperatures maintained by air conditioner systems following the Cool Biz and Super Cool Biz campaigns as strictly enforcing turning off of lights and electronic equipment when not in use.

The head office is promoting greater use of telework (work from home) and in January 2022 replaced individual desks with a free address system in its offices. Additionally, in July 2022, UACJ consolidated the head office functions of its affiliated companies in Otemachi, Tokyo as part of its efforts to further improve office space efficiency and to reduce energy consumption for air conditioning, lighting, and electronic equipment.

Office-Based Environmental Protection Measures

For office supplies, we are proactively sourcing items that comply with the Law Concerning the Promotion of Procurement of Eco-Friendly Goods and Services by the State and Other Entities and eco-mark items.