News Room 2015

Ceremony Marking the Start of Fully Integrated Manufacturing at the Rayong Works of UACJ (Thailand) Co., Ltd.

November 24, 2015

A ceremony commemorating the August 25, 2015 start of fully integrated manufacturing of flat rolled aluminum products at UACJ (Thailand) Co., Ltd. (Headquarters: Amata City, Rayong Province, Thailand; President: Akinori Yamaguchi; hereinafter, “UATH”), a wholly owned subsidiary of UACJ Corporation (Headquarters: Chiyoda-ku, Tokyo; President and CEO: Mitsuru Okada; hereinafter, “UACJ”), was held in Bangkok, Thailand on November 20. Among the approximate 500 invited guests were representatives of the governments of Thailand, Japan, and other countries, numbering around 20 in total, and customers and partner companies. The ceremony was also attended by UACJ chairman, Shigenori Yamauchi, and president, Mitsuru Okada, as well as UATH president, Akinori Yamaguchi.

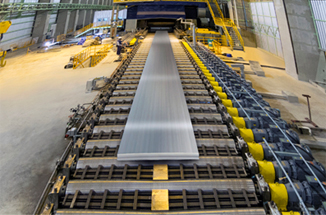

Having adopted the most advanced technology for its cutting-edge manufacturing facilities, UATH’s Rayong Works is the UACJ Group’s main producer of high-quality, cost-competitive flat-rolled aluminum products in Asia. With plans to be turning out 200,000 tons of flat-rolled products annually by 2017, and 300,000 tons annually in the future, the Rayong Works is set to provide flat-rolled aluminum products to customers not only in and around Southeast Asia, where growth is seen as a certainty, but also other regions including North America, the Middle East, and Africa.

UATH embarked on construction of the Rayong Works in March 2012 and commenced cold-rolling and finishing processes – the first phase of operational startup - in January 2014. Fully integrated manufacturing began in August 2015, when construction was completed on facilities for casting and hot rolling.

Having installed the world’s most advanced, and largest, casting and hot-rolling lines, cold-rolling mill, and surface treatment and painting lines, the Rayong Works is capable of supplying mainly Asian manufacturers of beverage cans and automobile parts with high-quality, high-value-added materials for the production of beverage cans, automobile heat exchangers, and other products. Moving forward, consideration will be given to expanding production facilities in line with demand increases to place the Rayong Works among the most advanced production facilities of its kind in Asia.

The Rayong Works is located on 500,000 square meters of land within the Amata City Industrial Estate in the eastern Thai province of Rayong, an area with the strategic benefit of easy export from Laem Chabang Port. At an elevation of 104 meters above sea level, the Rayong Works is at low risk of damage from tsunamis and floods.

In its Global Step I mid-term management plan, UACJ has put forth “Expand growth products in the transportation field – focusing on automobiles – and the energy field, and strengthen business in growth regions such as Asia” as one of its major policies. With the start of fully integrated manufacturing at the Rayong Works, the strengthening of manufacturing locations in Asia has assumed more concrete dimensions. By capturing demand in the Asian market, which is growing at an exceptional rate, the flat-rolled aluminum products business, with contributions from existing manufacturing bases in the U.S., China, Europe, and other locations, will achieve a stronger position in the global market, and continue to respond to wide-ranging customer needs.

Overview of UACJ (Thailand) Co., Ltd.

| Company name | UACJ (Thailand) Co., Ltd. |

|---|---|

| Representative | President, Akinori Yamaguchi |

| Location | Headquarters, Rayong Works: Amata City Industrial Estate 7/352 Moo 6, Tambol Mabyangporn, Amphur Pluakdaeng, Rayong Province 21140, Thailand Sales office: No.689 Bhiraj Tower at EmQuartier 26th FL., Room No.2602-2608, Sukhumvit Road, Klongton Nue, Wattana, Bangkok 10110, Thailand |

| Paid-in capital | 12.5 billion Thai baht |

| Employees (as of September 30, 2015) |

680 |

Overview of UACJ (Thailand) Co., Ltd. Rayong Works

| Site area | 500,000 m2 |

|---|---|

| Area under roof | Approx. 110,000 m2 |

| Main facilities and specifications | Casting line, hot-rolling line, cold-rolling mill, slitter, surface treatment and painting lines, etc. Hot-rolling rough mill specifications: Type: 4-high Reversing Mill Max. speed: 180 m/min Max. width: 2,250 mm(Roll face length: 2,500 mm) Max. weight: 30 tons Hot finishing rolling mill specifications: Type: 4-high 4-stand Tandem Mill Max. speed: 550 m/min Max. width: 2,250 mm(Roll face length: 2,500 mm) Max. weight: 28 tons |

| Production capacity (as of Sept. 30, 2015) |

192,000 tons |

| Products | Materials for the manufacture of beverage cans, automotive heat exchangers, and other products |

UATH’s Rayong Works, where fully integrated manufacturing was recently started, and its hot-rolling mill

Scene from the commemoration ceremony held on November 20, 2015 in Bangkok, Thailand

From left: UATH president, Mr. Akinori Yamaguchi; Minister of the Embassy of Japan in Thailand, Mr. Akihiko Uchikawa; UACJ chairman, Mr. Shigenori Yamauchi; Thai Minister of Industry, H.E. Dr. Atchaka Sibunruang; UACJ president, Mr. Mitsuru Okada; Secretary General, Board of Investment of Thailand, Ms. Hirunya Suchinai