Forged Products

Axle Bearing Housing for N700 Shinkansen (Bullet Train)

- HOME

- Products

- Forged Products

- Axle Bearing Housing for N700 Shinkansen (Bullet Train)

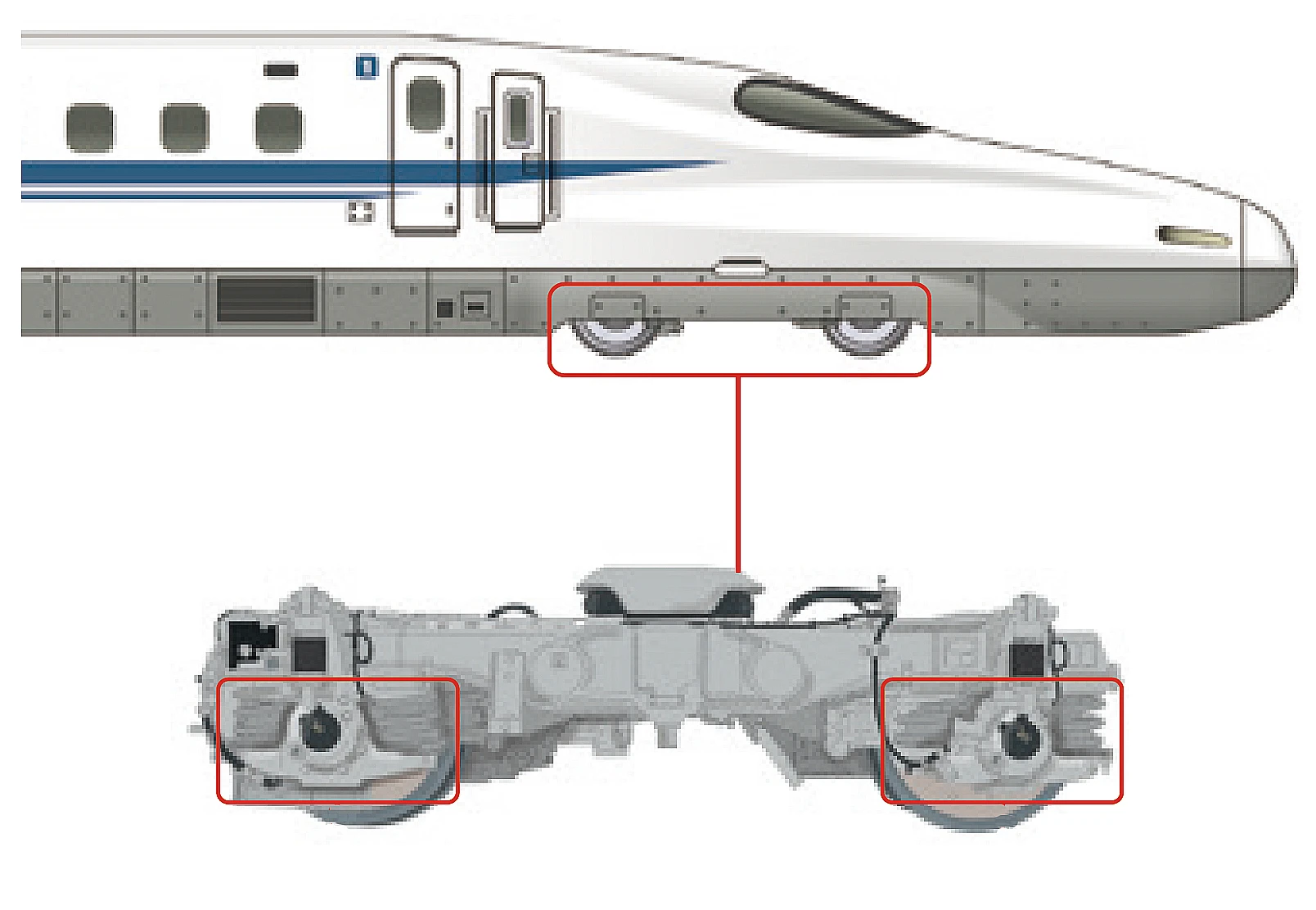

In the Underbody of High-Speed Railcars (Wheel Bearings)

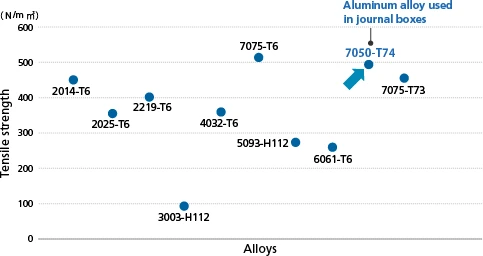

As rail speeds have increased in recent years, manufacturers have begun using 7050, a high-strength aluminum alloy that is forged at high temperature and pressure, for railcar bearings (journal boxes). This reduces their unsprung weight, gives cars greater stability and reduces fuel consumption. These features allow us to propose to customers the use of these housings in important high-speed vehicle components.

Features

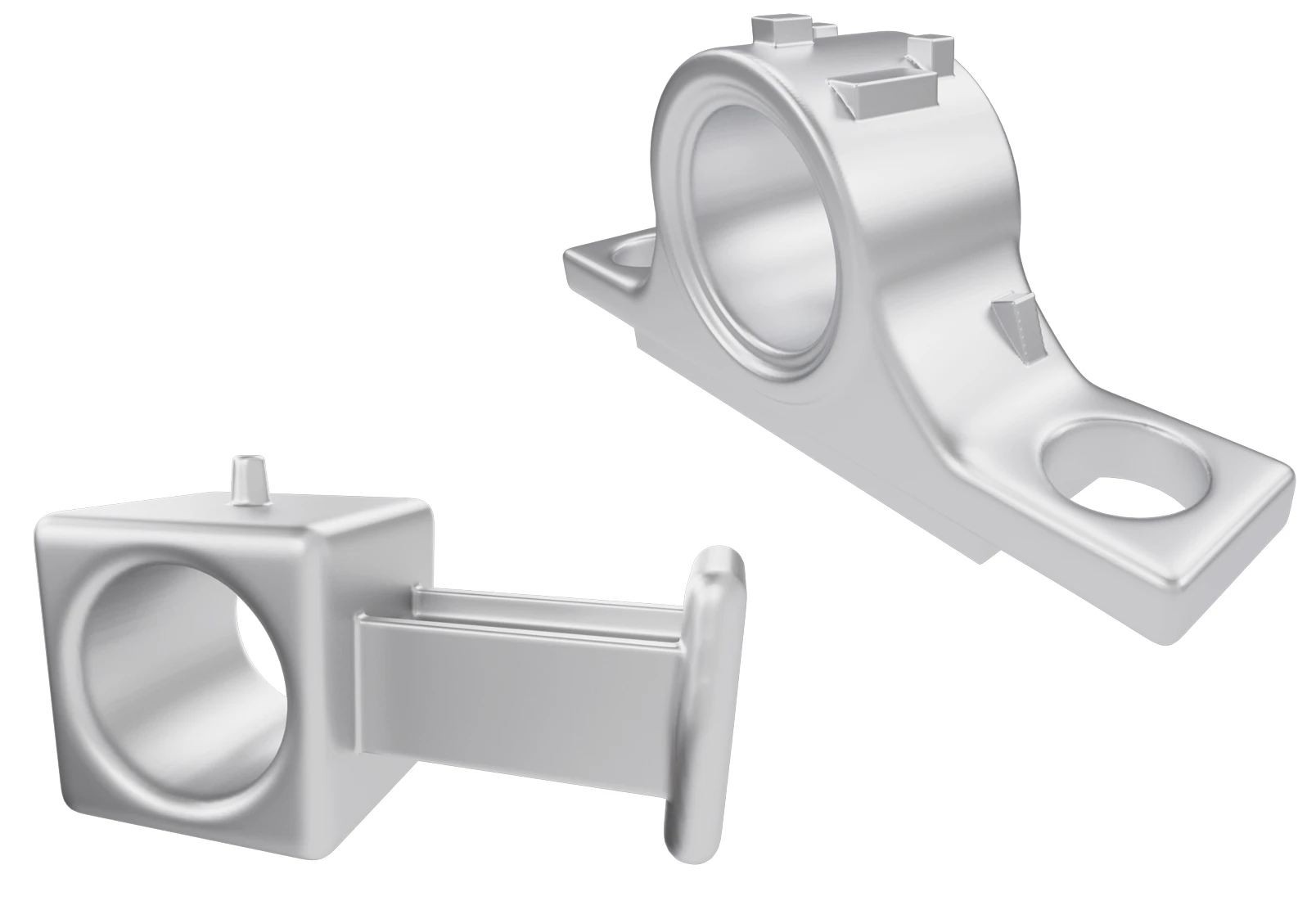

- Die forging and free forging can both be used to deliver products to specifications. Die produces items in shapes predetermined by the die, thereby minimizing the need for machining.

- 7050-T74 can be used when high strength is needed, as can be incorporated into heavy walled, heat-treated parts.

- This material has a specific weight of 2.8, making it one-third the weight of ferrous materials.

Applications

Journal box for wheel bearings of high-speed railcars

Location where used in journal boxes (Axle Bearing Housing)

- Specified location: Wheel journal box

- Production method: Die forging

- Advantage: Reduces unsprung weight

Product Characteristics

Tensile strength of typical aluminum alloy