Pick Up

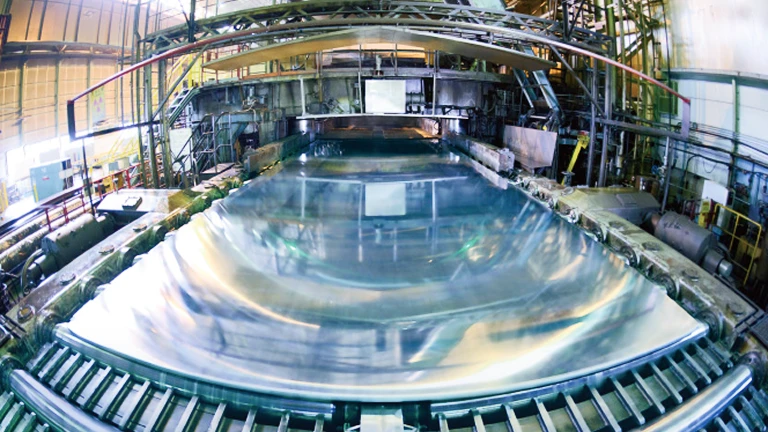

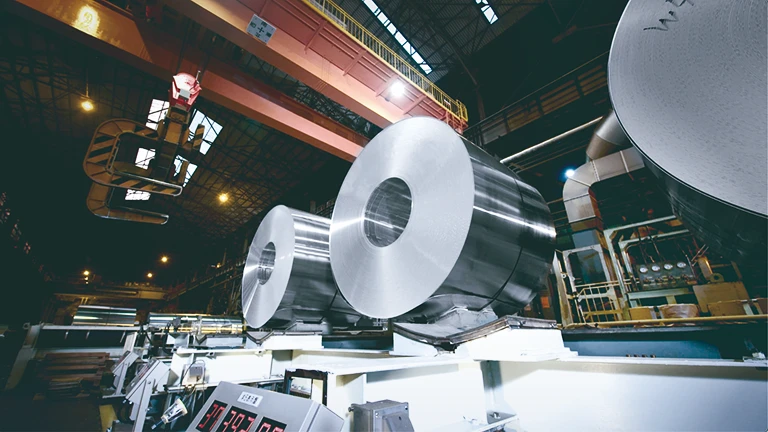

Promoting

aluminum recycling toward

a sustainable society

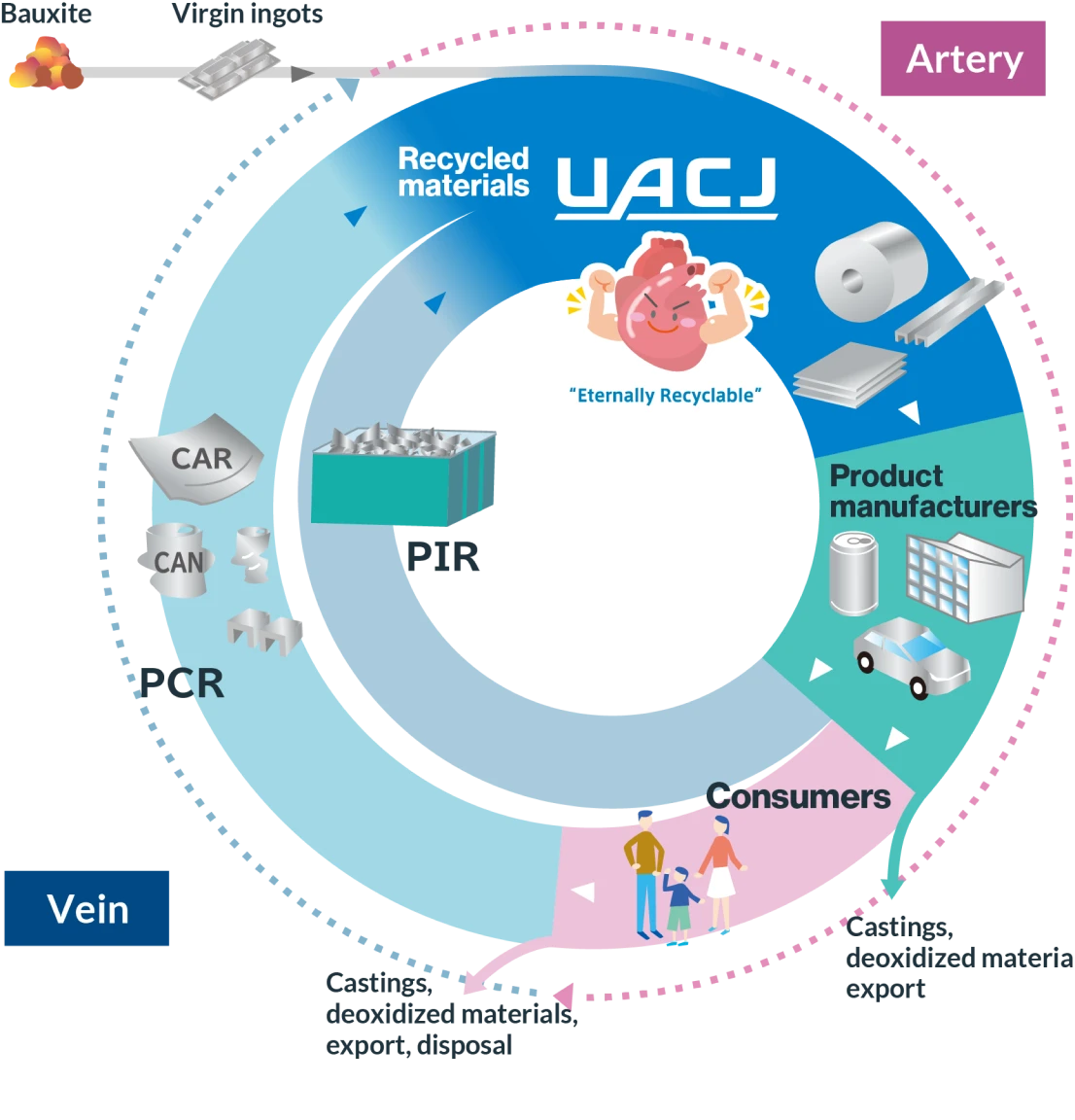

As a world-leading comprehensive aluminum manufacturer,

we serve as the "heart" of the aluminum recycling cycle,

contributing to industry development

and the realization of a sustainable society.

Important Notice

Information on Products and Technology

Technology and R&D

-

Here, we introduce the Group's philosophy, company profile, business summary, and domestic and overseas locations.

-

We also provide investor relations materials, growth strategies, financial data, and performance information, etc.

-

Here, we introduce our efforts toward the realization of a sustainable world.

Our Approach to Sustainability

A Future where the Earth can Continue to be Beautiful and Bountiful

A Healthy and Harmonious Society where Everyone can Feel Well-being