Flat Rolled Products

Aluminum Alloy Sheets for Beverage Containers

- HOME

- Products

- Flat Rolled Products

- Aluminum Alloy Sheets for Beverage Containers

For Food and Beverage Containers

Aluminum cans are widely used in food product containers because they are lightweight, seal well, conduct heat and are easy to recycle. As demand increases for containers that address environmental issues, are functional and that can be crafted into attractive new designs, we are collaborating with clients to develop new materials that will help aluminum cans make even further inroads.

Features

- The can body sheets are reduced and high pressure resistance (full foam) can lid materials are used.

- The mixture of raw materials, downward pressure on the roller and temperature controls are adjusted to achieve optimal strength and processing hardness.

- The soaking temperature and duration, downward pressure on the roller and temperature control are used to achieve the optimal metallic structure and control the amounts of solute and precipitate.

- Can lids are made of CPCL. A uniform coating helps maintain high corrosion resistance.

Product Characteristics and Process Design

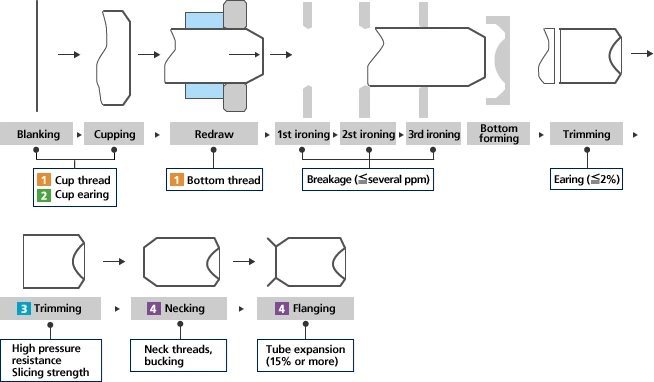

Aluminum Can Body Sheet Materials: Required Characteristics and Process Design

Preventing wrinkles and breaks

Controlling strength and processing hardness

- Composition of alloy

- Homogeneity conditions

- Cold rolling: downward rolling pressure, curling temperature

Sidewall control

Texture control

- Homogeneity conditions

- Hot rolling: downward rolling pressure, temperature

- Cold rolling: downward rolling pressure

Post-baking hardness

Control amount of solute/precipitate

- Homogeneity conditions

- Hot rolling: temperature

- Cold rolling: curling temperature

Necking, flanging

Control of strength and processing hardness

- Homogeneity conditions

- Cold rolling: downward rolling pressure, curling temperature

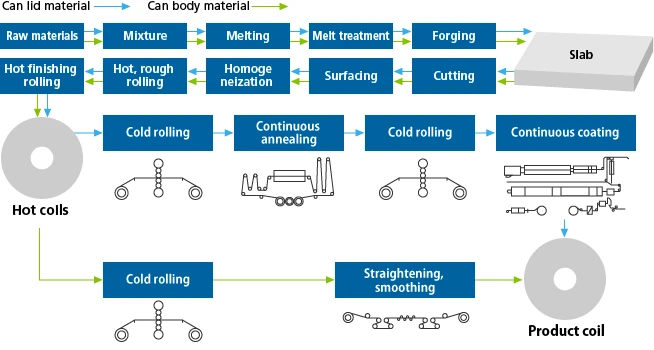

Production Process

Can stock production process

- Can body materials utilize self-annealing (SA) process