Flat Rolled Products

Aluminum Alloys for Lithium-ion Battery Sealing Materials

- HOME

- Products

- Flat Rolled Products

- Aluminum Alloys for Lithium-ion Battery Sealing Materials

Features

- The materials exhibit high weldability in laser welding (melting deeply and stably into each other).

- They are scarcely work-hardened in the explosion-proof valve machining range and are highly formable.

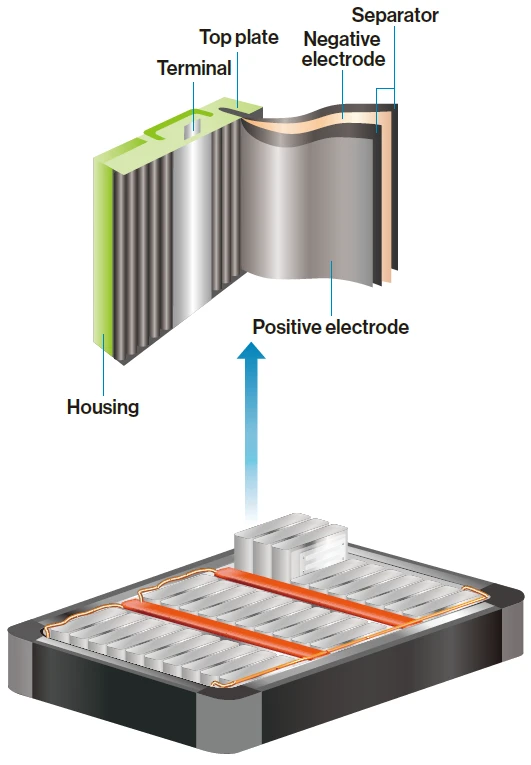

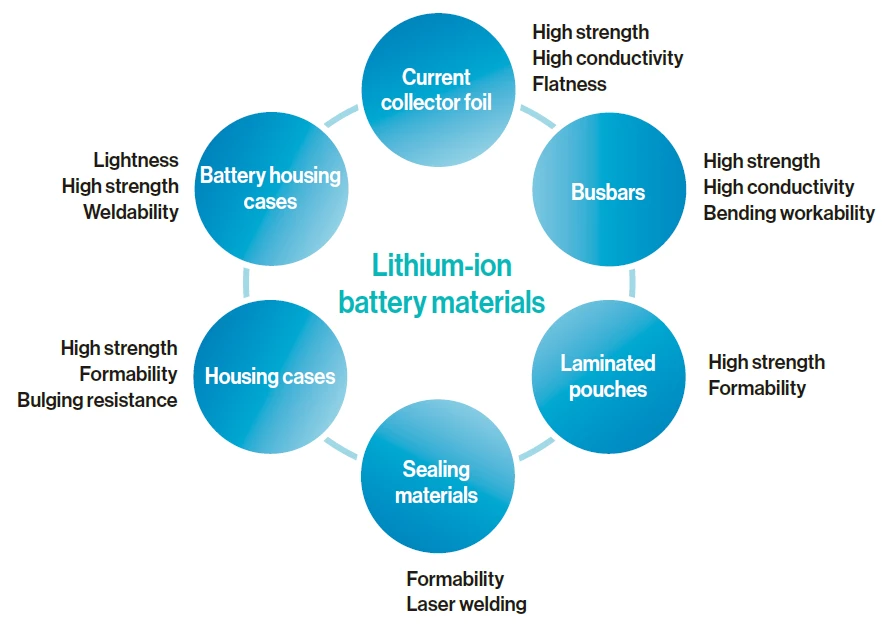

Lithium-ion battery related materials

- Battery housing cases

- Housing materials and sealing materials

- Peripheral members (busbar and tab-lead materials)

- Current collector aluminum foils

Mechanical properties

| Alloy | JIS name | Temper | Mechanical properties | Material properties | Features | |||

|---|---|---|---|---|---|---|---|---|

| Tensile strength (N/mm2) |

Proof stress (N/mm2) |

Elongation (%) |

Explosion-proof valve formability | Laser welding | ||||

| FS110 | 8079 | H12 | 105 | 95 | 21 | ◎ | ◎ | High-strength Al-Fe alloys High weldability in laser welding Easy explosion-proof valve machining |

| 303S | 3003 | O | 115 | 55 | 34 | △ | ○ | Standard Al-Mn alloys |

| H14 | 160 | 150 | 7 | |||||

| A350 | 1050 | O | 85 | 40 | 42 | ◎ | △ | Standard pure-aluminum |

- ◎:Very good ◯:Good △:Rather poor ✕:Poor